Silica particles for electrode material and preparation method and application of silica particles

An electrode material and particle technology, applied in the field of silicon-oxygen particles and their preparation, can solve the problems of electrolyte consumption, complex preparation process, large polarization, etc., and achieve the effects of reducing lithium ion loss, reducing specific surface area, and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Preparation method

[0058] 1.1 Preparation of secondary particles

[0059] Get 100kg of silicon oxide powder (i.e. primary particle, D10=0.60 μm, D50=1.78 μm, D90=3.59 μm, SPAN=1.68, x=1 in SiOx general formula, specific surface area 8.9m 2 / g) and 12kg of coal tar pitch powder were added to the VC mixer, and mixed for 30 minutes at a speed of 16m / s at the maximum diameter of the stirring part, so that the two raw materials were evenly mixed. Subsequently, the rotation speed was reduced to reduce the aforementioned linear velocity to 8m / s, and at the same time, nitrogen gas was introduced as an inert protective gas, and then the temperature was raised at a rate of 3°C / min, and the temperature was raised to 300°C and kept for 4h, and then naturally cooled to room temperature. Complete the granulation process of silicon oxide and pitch. During this process, as the temperature in the VC mixer rises, the asphalt gradually softens, and is evenly coated on the surface o...

Embodiment 2

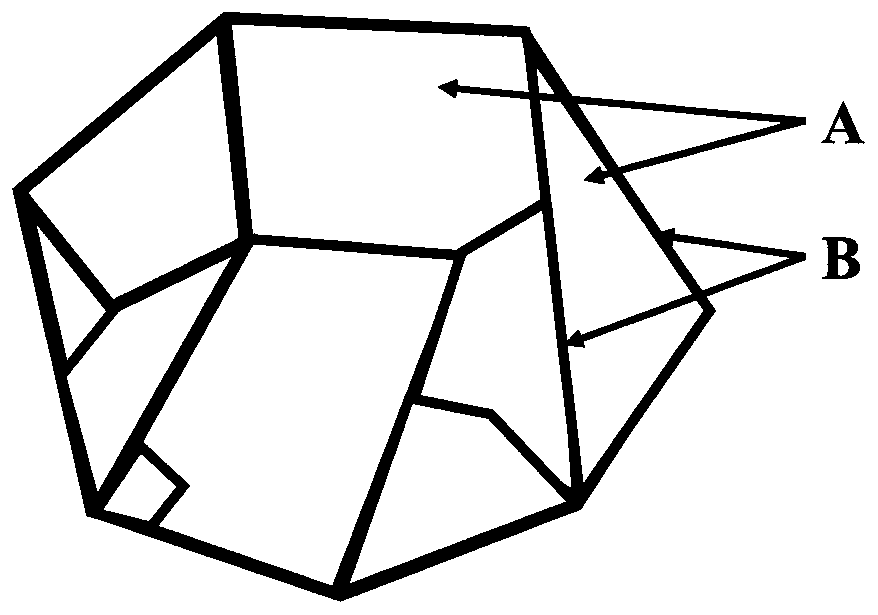

[0077] The process of Example 2 is similar to Example 1, the difference is that in the material synthesis process, in addition to taking 100kg of silicon oxide powder and 12kg of coal tar pitch powder into the VC mixer, an additional 0.3kg of Ketjen black and 0.2 kg of multi-walled carbon nanotube conductive additive powder. The final product is therefore a silica / amorphous carbon composite secondary particle containing conductive additives with a structure such as image 3 As shown, the material is composed of silicon oxide primary particles A, conductive additive C and a carbon layer B that connects and coats the two. The conductive additive C is evenly dispersed inside and outside the secondary particles. D10=1.78μm, D50=3.89μm, D90=7.01μm, SPAN=1.34 of the final product, and the specific surface area is 3.0m 2 / g, tap density 0.84g / cm 3 , the carbon content is 5.3wt%, and the grain size corresponding to the Si(111) crystal plane is 2.9nm.

[0078] The half-cell and full...

Embodiment 3

[0080]Get 100kg of secondary granules made in Example 1, and get 1kg of petroleum pitch powder, add VC mixer, mechanically mix under the condition of line speed 3m / s after 10 minutes, slow down to 2m / s, in nitrogen protection atmosphere The device was heated to 300° C. for 1 h while stirring, and then slowly cooled to room temperature. The above pitch-coated material was kept at 400°C for 2 hours in an argon inert atmosphere, then heated to 900°C for carbonization for 4 hours, naturally cooled to room temperature, crushed, sieved and demagnetized to obtain a second layer of amorphous Carbon coated silica / amorphous carbon composite particles. The final product has D10=2.13μm, D50=4.65μm, D90=7.87μm, SPAN=1.23, and the specific surface area is 2.4m 2 / g, tap density 0.95g / cm 3 , the carbon content is 5.8wt%, and the grain size corresponding to the Si(111) crystal plane is 2.9nm.

[0081] The half-cell and full-cell evaluation methods are the same as in Example 1, and the resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com