Natural gas or hydrogen filling system and filling method

A filling system and natural gas technology, applied in the field of energy gas filling control, can solve problems such as temperature rise, unsatisfactory natural gas temperature control, failure to achieve the purpose of natural gas filling control, etc., so as to reduce gas flow heating and offset temperature rise. Defects, effects of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

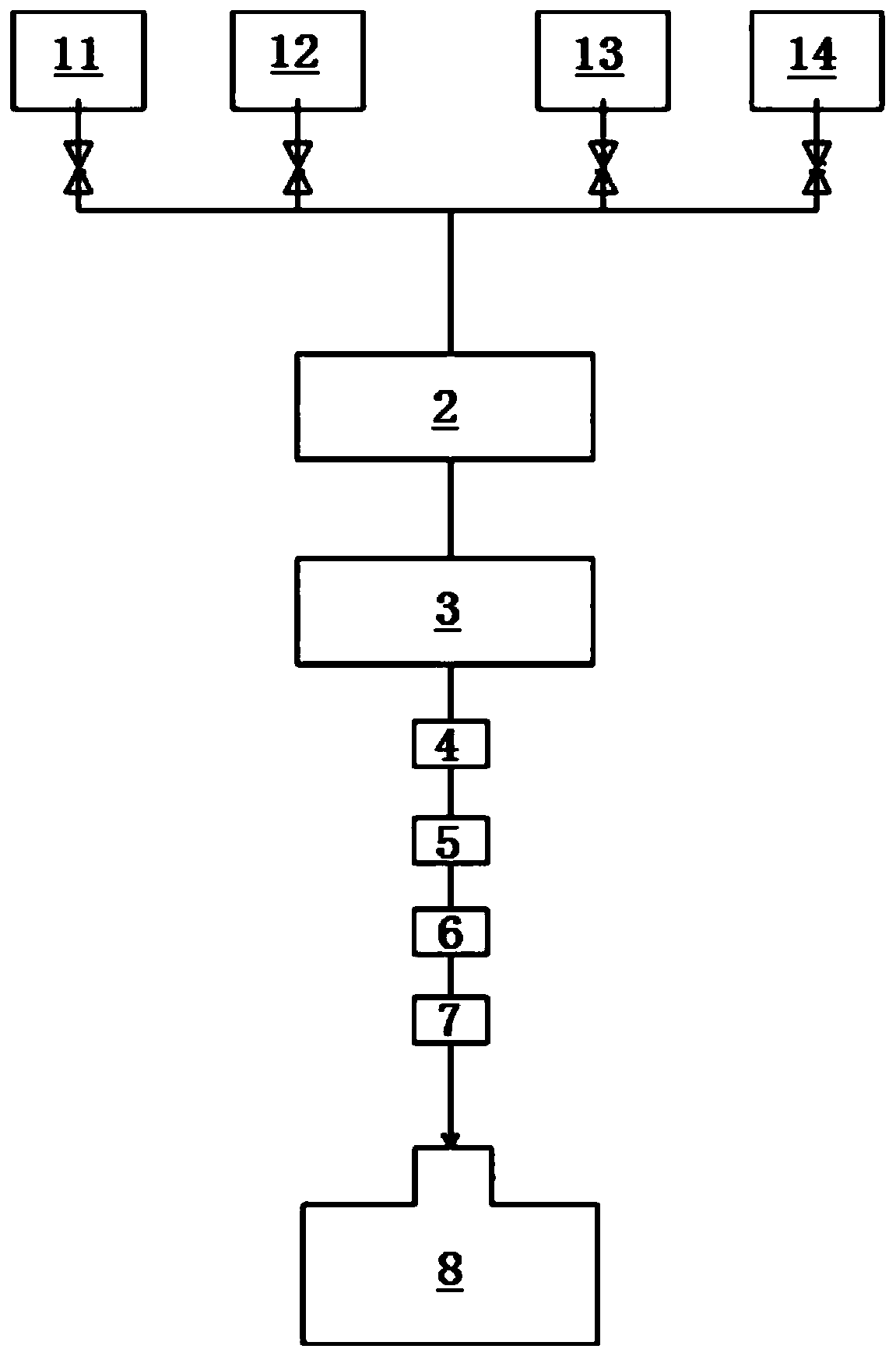

[0088] Such as figure 1 The natural gas or hydrogen filling system shown includes multi-stage air pressure charging tanks 11-14, mixed charging pipelines, multi-stage charging switching valves, multi-stage charging control precooling devices and charging valves. The multistage air pressure charging tank comprises the first gas storage tank 11 (high pressure gas tank), the second gas storage tank 12 (medium pressure gas tank), the third gas storage tank 13 (low pressure gas tank), the fourth gas storage tank 14 (shared gas tank or spare gas tank). The four gas storage tanks are respectively set with different pressures, for example, the pressure of the first gas storage tank is 70MPa, the pressure of the second gas storage tank is 50MPa, the pressure of the third gas storage tank is 25MPa, and the pressure of the fourth gas storage tank is 45MPa. The natural gas in the gas storage tanks is pressurized to a gradually increasing pressure state, and each gas storage tank is respe...

Embodiment 101

[0094] A method for filling natural gas or hydrogen, using the natural gas or hydrogen filling system as described in Example 1 to fill natural gas, prevent the temperature of the gas from rising, and control the temperature of the gas storage cylinder on the passenger car to keep it within a safe range , improve filling efficiency. The specific filling method is as follows.

[0095] (1) Use the movable expansion joint to connect with the bottle mouth valve on the gas cylinder on the passenger car.

[0096] (2) Open the third gas storage tank 13 (low pressure gas tank, 25Mpa), the second gas storage tank 12 (medium pressure gas tank, 50Mpa) and the first gas storage tank 11 (high pressure gas tank) in sequence according to the order of air pressure from low to high. Gas tank, 70Mpa) for filling, while adjusting the cooling power of the pre-cooler to keep the temperature of the filling gas stable; until the filling of the gas storage cylinder is completed.

[0097] In the spe...

Embodiment 2

[0110] A natural gas filling system capable of preventing the gas temperature from rising, including high, medium and low three-level air pressure gas filling tanks + a shared four-level pressure drop pipeline, and the four-level gas filling tanks are respectively equipped with inflation switch valves to realize four-level inflation control . The decompression pipeline is connected to the mixed gas pipeline, and then the mixed gas pipeline is connected to the precooling device. The gas storage tanks include a first gas storage tank, a second gas storage tank, a third gas storage tank, and a fourth common gas storage tank. Set different pressures for the four-stage gas storage tanks + pipelines, for example, the pressure of the first gas storage tank is 70MPa, the pressure of the second gas storage tank is 60MPa, the pressure of the third gas storage tank is 50MPa, and the pressure of the fourth common gas storage tank is 40MPa. The natural gas pressurization process is in a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com