A pressure relief method for overlying residual coal pillars at short distances

A short-distance, coal-pillar technology, applied in earthwork drilling, surface mining, underground mining, etc., can solve problems such as weak pressure relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

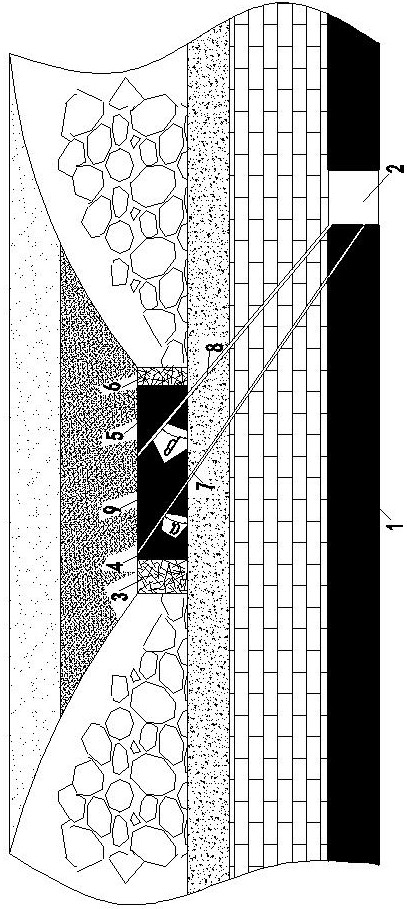

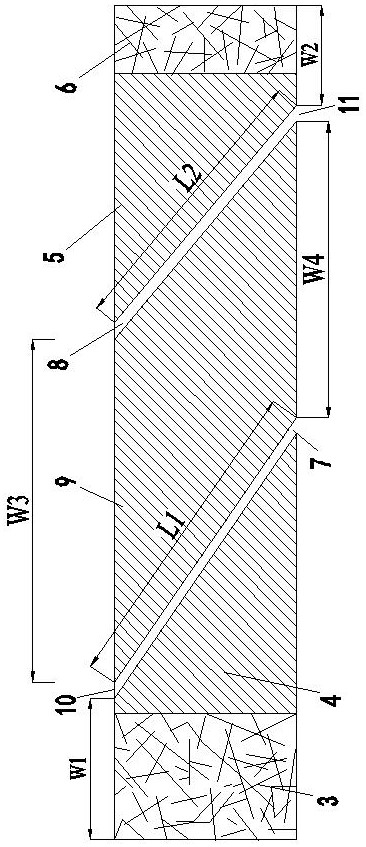

[0053] The width of the residual coal pillar in the No. 2.3 coal seam in a coal mine is 16m, the height is 4.57m, the thickness of the underlying No. 4 coal seam is 3.05m, and the distance between the No. 2.3 coal seam and the No. 4 coal seam is 10m. The distance to the left side of the underlying coal seam is 10m.

[0054] (1) Sampling by drilling, collecting 5 coal samples from the overlying coal seam on site;

[0055] (2) Process the coal samples obtained in step (1) into 6 standard test pieces in the laboratory, conduct variable-angle shear experiments, and measure the cohesion of the coal samples , coal seam internal friction angle ;

[0056] (3) The coal sample cohesion C and internal friction angle measured according to step (2) , to determine the width X of the crushed zone 6 formed by the impact of primary mining in the coal pillar 1 :

[0057]

[0058] Where: the height of the overlying coal pillar M =4.57m; Coal seam Poisson's ratio , side pressure coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com