A method of vacuum sintering method for laser cladding preparation coating process

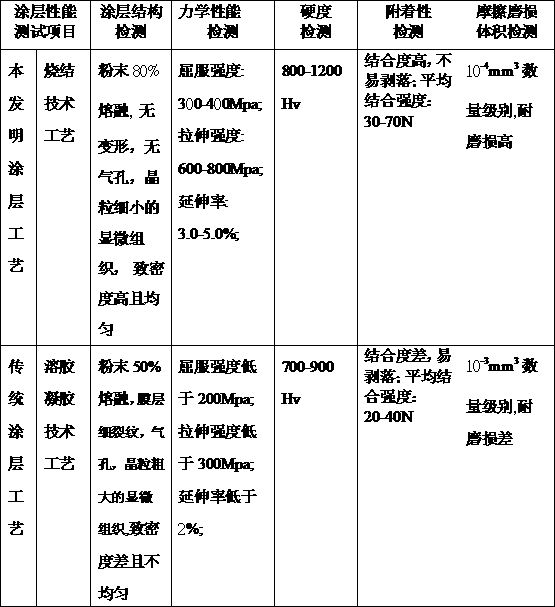

A laser cladding, vacuum sintering technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of low coating quality, difficult to meet technical requirements, powder waste, etc. 1. The effect of high powder utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Pre-treat the substrate to remove dust, grease and rust on the surface of the substrate;

[0049] (2) Powder treatment, place the mixed powder in a planetary ball mill, and then put it in a drying oven to dry for 3 hours, then, mix the mixed powder evenly into the adhesive to achieve the uniform mixing and blending of the powder to be clad into a paste or Paste, ready for use; (3) Spread the powder to be clad in paste or paste on the surface of the substrate in different forms by screen printing; (4) Preset the paste or paste on the surface of the substrate by screen printing The powder to be clad is dried in a high-temperature oven, then heated and hardened in a vacuum at 800°C for 12 hours, and sintered to form a preset layer; Melting under the assistance of ultrasonic waves produces a molten pool to form a pseudo-solid coating, so that the pre-set layer and the base material can be metallurgically bonded to obtain a composite coating. The process parameters of t...

Embodiment 2

[0051] (1) Pre-treat the substrate to remove dust, grease and rust on the surface of the substrate;

[0052] (2) Powder treatment, place the mixed powder in a planetary ball mill, and then put it in a drying oven to dry for 3 hours, then, mix the mixed powder evenly into the adhesive to achieve the uniform mixing and blending of the powder to be clad into a paste or Paste, ready for use; (3) Spread the powder to be clad in paste or paste on the surface of the substrate in different forms by screen printing; (4) Preset the paste or paste on the surface of the substrate by screen printing The powder to be clad is dried in a high-temperature oven, then heated and hardened in a vacuum at 1200°C for 12 hours, and sintered to form a preset layer; Ultrasonic-assisted melting is performed to generate a molten pool to form a pseudo-solid coating, so that the pre-set layer and the base material are metallurgically bonded to obtain a composite coating. The process parameters of the abov...

Embodiment 3

[0054] (1) Pre-treat the substrate to remove dust, grease and rust on the surface of the substrate;

[0055] (2) Powder treatment, place the mixed powder in a planetary ball mill, and then put it in a drying oven to dry for 3 hours, then, mix the mixed powder evenly into the adhesive to achieve the uniform mixing and blending of the powder to be clad into a paste or Paste, ready for use; (3) Spread the powder to be clad in paste or paste on the surface of the substrate in different forms by screen printing; (4) Preset the paste or paste on the surface of the substrate by screen printing The powder to be clad is dried in a high-temperature oven, then heated and hardened in a vacuum at 900°C for 12 hours, and sintered to form a preset layer; Melting under the assistance of ultrasonic waves produces a molten pool to form a pseudo-solid coating, so that the pre-set layer and the base material can be metallurgically bonded to obtain a composite coating. The process parameters of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com