Moisture permeation, ventilation and high hydrostatic pressure breathable film and preparation method thereof

A technology of hydrostatic pressure and breathable membrane, which is applied to flat products, other household appliances, applications, etc. It can solve the problems of high moisture permeability of breathable membranes, high air permeability and high hydrostatic pressure cannot coexist, and achieve excellent physical properties and uniform moisture permeability , High resistance to external pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

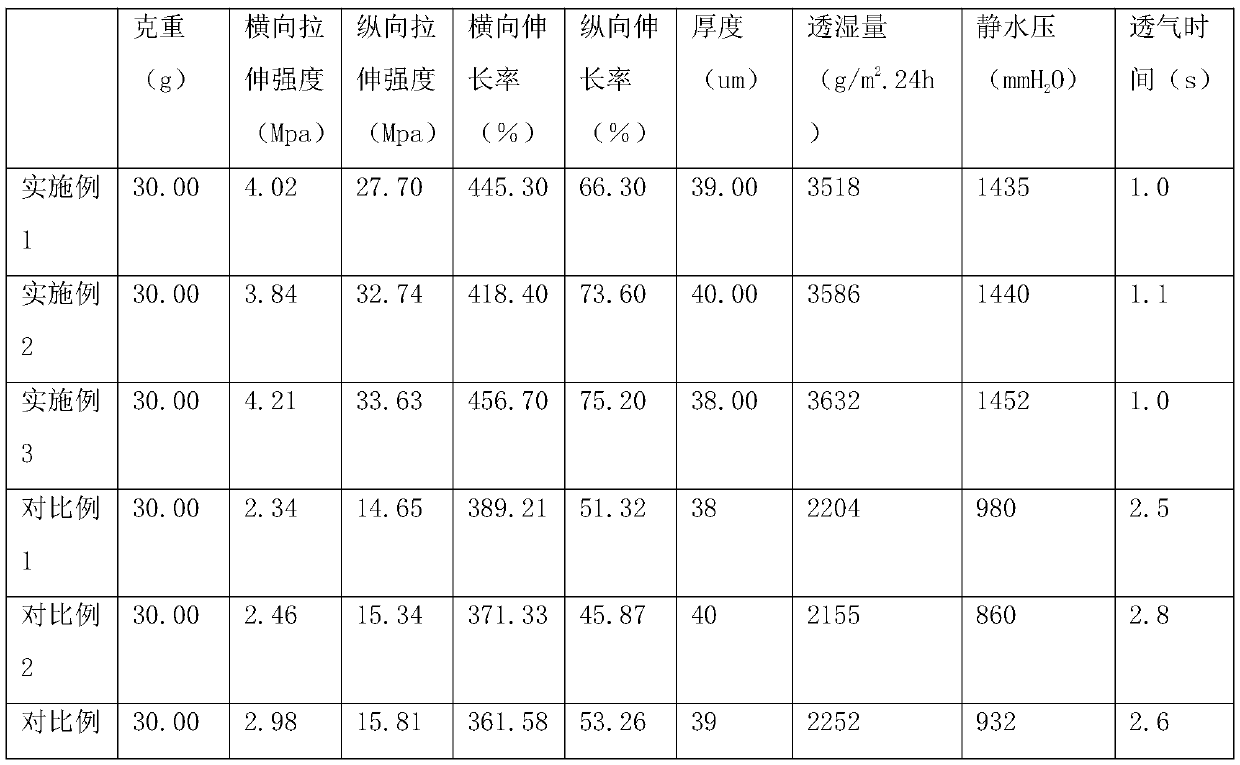

Embodiment 1

[0029] Embodiment 1: the preparation of breathable film

[0030] The method comprises the following steps: (1) uniformly feeding the raw materials metallocene linear low-density polyethylene, linear low-density polyethylene and calcium carbonate fine powder with a particle size of 2 μm respectively using a feeder; the raw materials are calculated by weight percentage : Metallocene linear low density polyethylene is 5%, linear low density polyethylene is 10%, breathable material is 85%;

[0031] (2) The mixture is extruded through a three-layer co-extrusion and melted, and then extruded through a die, wherein the screw temperature on both sides is 185°C, the middle screw temperature is 190°C, and the die head temperature is 190-200°C;

[0032] (3) Cooling after blowing the film to form a film bubble; when blowing the film, it is blown by cold wind, and the temperature of the cold wind is 12-18°C; cooling is carried out at a room temperature of 20-25°C by air flow;

[0033] (4)...

Embodiment 2

[0036] Embodiment 2: the preparation of breathable film

[0037] The method comprises the following steps: (1) uniformly feeding the raw materials metallocene linear low density polyethylene, linear low density polyethylene and calcium carbonate fine powder with a particle size of 5 μm respectively using a feeder; the raw materials are calculated by weight percentage : Metallocene linear low density polyethylene is 15%, linear low density polyethylene is 15%, breathable material is 70%;

[0038] (2) The mixture is extruded through a three-layer co-extrusion and melted, and then extruded through a die, wherein the screw temperature on both sides is 185°C, the middle screw temperature is 190°C, and the die head temperature is 190-200°C;

[0039] (3) Cooling after blowing the film to form a film bubble; when blowing the film, it is blown by cold wind, and the temperature of the cold wind is 12-18°C; cooling is carried out at a room temperature of 20-25°C by air flow;

[0040] (4...

Embodiment 3

[0043] Embodiment 3: the preparation of breathable film

[0044] The method comprises the following steps: (1) uniformly feeding the raw materials metallocene linear low-density polyethylene, linear low-density polyethylene and calcium carbonate fine powder with a particle size of 2 μm respectively using a feeder; the raw materials are calculated by weight percentage : Metallocene linear low density polyethylene is 20%, linear low density polyethylene is 20%, breathable material is 60%;

[0045] (2) The mixture is extruded through a three-layer co-extrusion and melted, and then extruded through a die, wherein the screw temperature on both sides is 185°C, the middle screw temperature is 190°C, and the die head temperature is 190-200°C;

[0046] (3) Cooling after blowing the film to form a film bubble; when blowing the film, it is blown by cold wind, and the temperature of the cold wind is 12-18°C; cooling is carried out at a room temperature of 20-25°C by air flow;

[0047] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com