Method for repairing spindle taper hole through autogenous grinding device

A technology of taper hole and spindle, which is applied in the direction of grinding drive device, grinding automatic control device, grinding machine tool parts, etc., which can solve the problem that the grinding process is not given a clear calculation formula of taper, and the accuracy of final taper repair cannot be accurately detected. , affecting grinding accuracy and other issues, to achieve the effect of simple and easy-to-understand calculation principles, reduce external factor interference, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

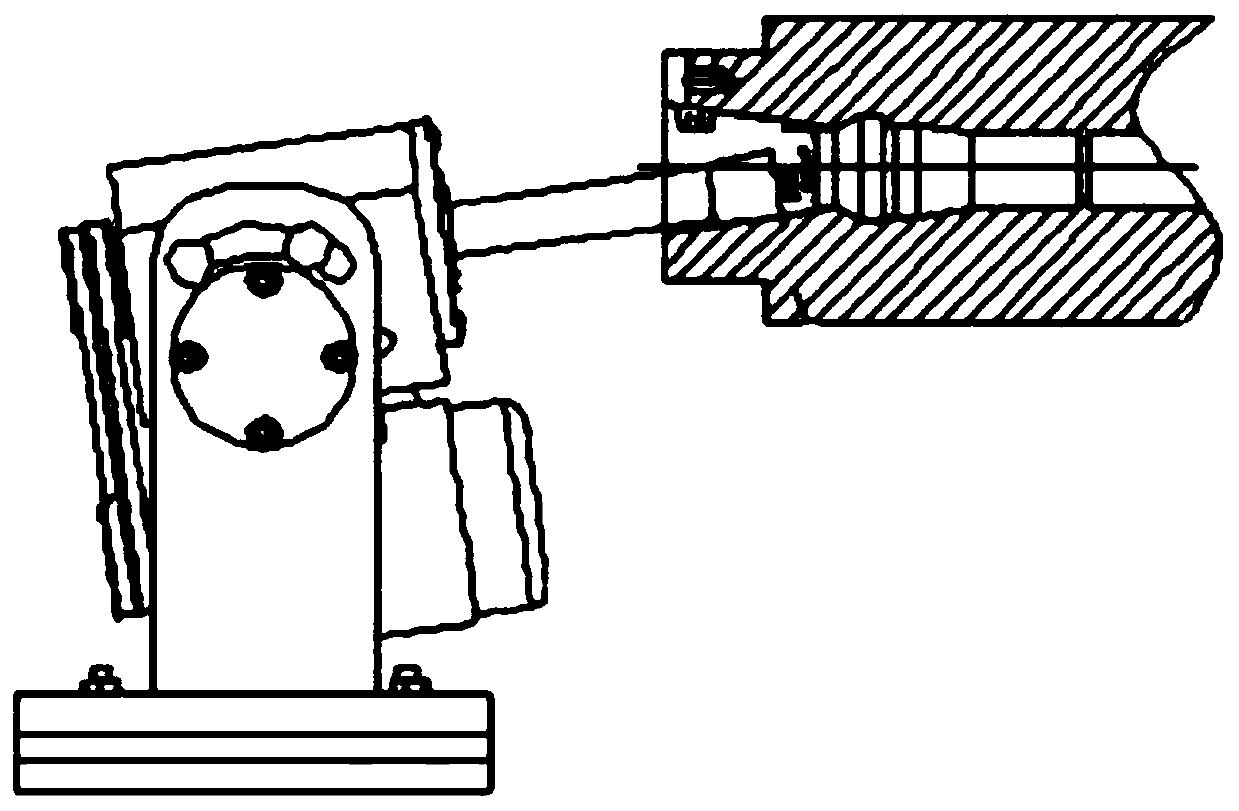

[0061] A method for repairing the taper hole of the main shaft using an autogenous grinding device of the present invention adopts a repairing device for the taper hole of the main shaft of a machine tool (self-grinding machine for short) to repair

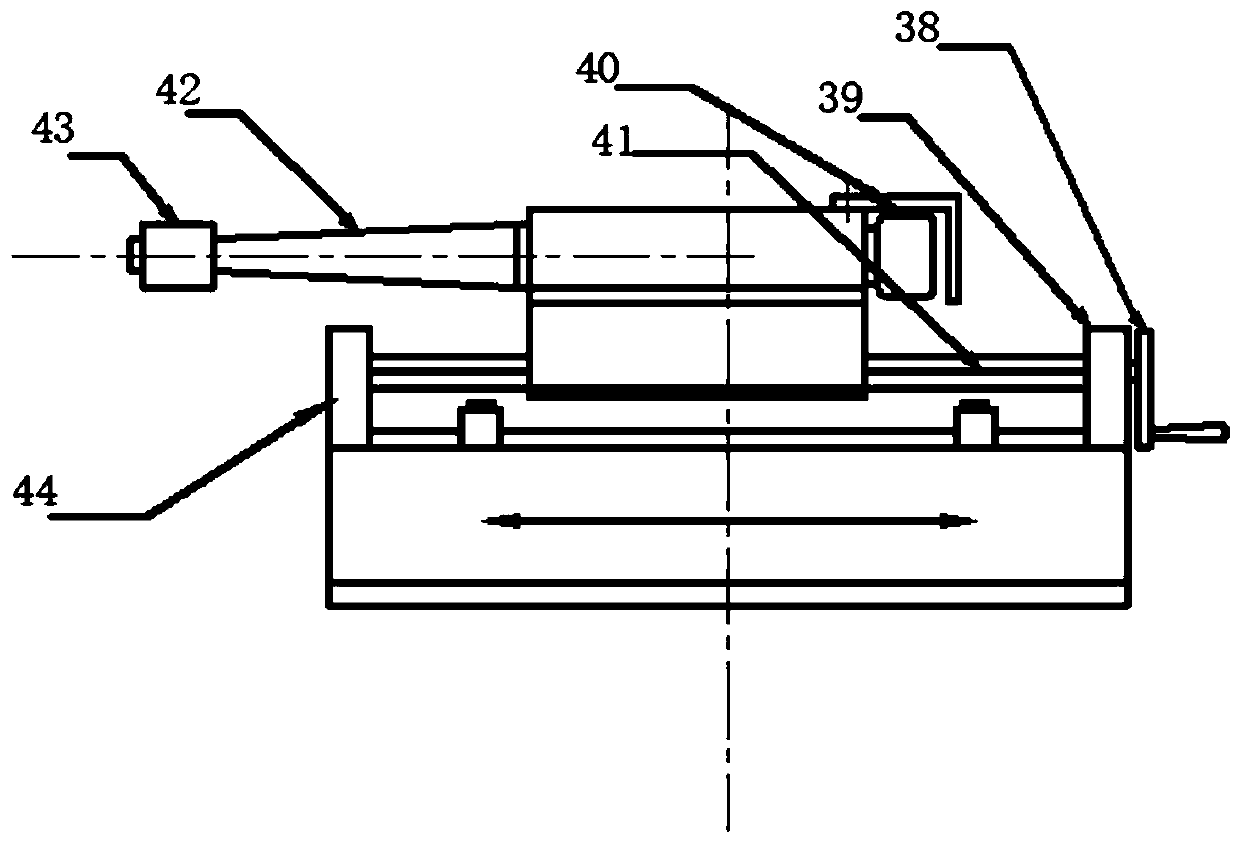

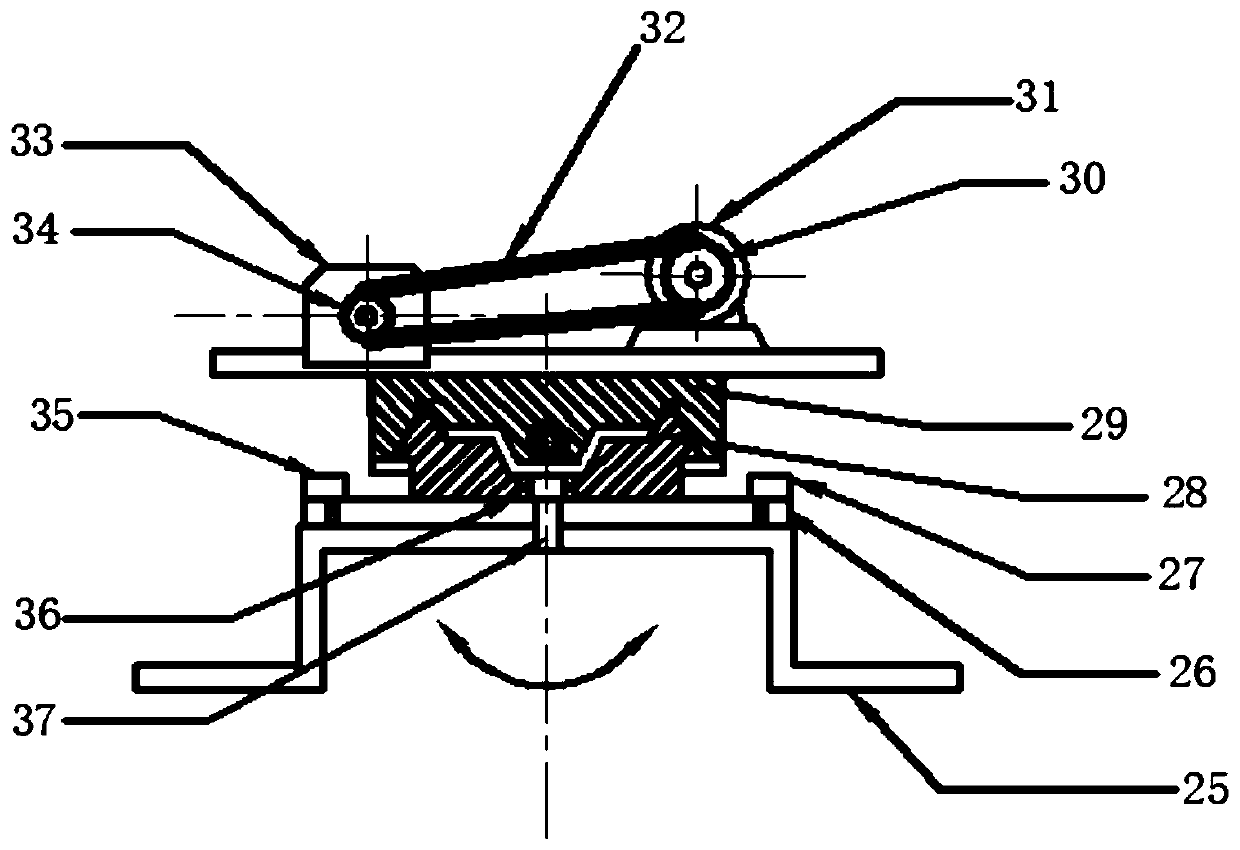

[0062] Described a kind of machine tool spindle taper hole repairing device (abbreviation self-grinding machine), such as figure 2 , 3 Shown: mainly composed of base 25, guide rail bottom plate 26, pressure plate 27, pressure plate 35, bearing 36, rotary shaft 37, guide rail 28, feed carriage 29, lead screw 41, lead screw support 39, handwheel 38, lead screw support 44, grinding wheel main shaft cover 33, grinding wheel main shaft 42, grinding wheel 43, belt pulley 34, protective cover 40, transmission belt 32, belt pulley 30, motor 31 constitute.

[0063] Guide rail base plate 26 is fixed on the base 25, and guide rail 28 is fixed on guide rail base plate 26, and guide rail 28 central holes are connected rotary shaft 37 by bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com