Screen printing plate structure of monocrystalline silicon solar cell

A solar cell and monocrystalline silicon technology, applied in the field of solar cells, can solve the problems of positive electrode current conduction affecting the whole cell, easy cracking and breaking of the edge of the cell, large shading area of the positive electrode, etc. Metal conduction resistance, avoiding easy cracking and breaking, reducing the effect of damage probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

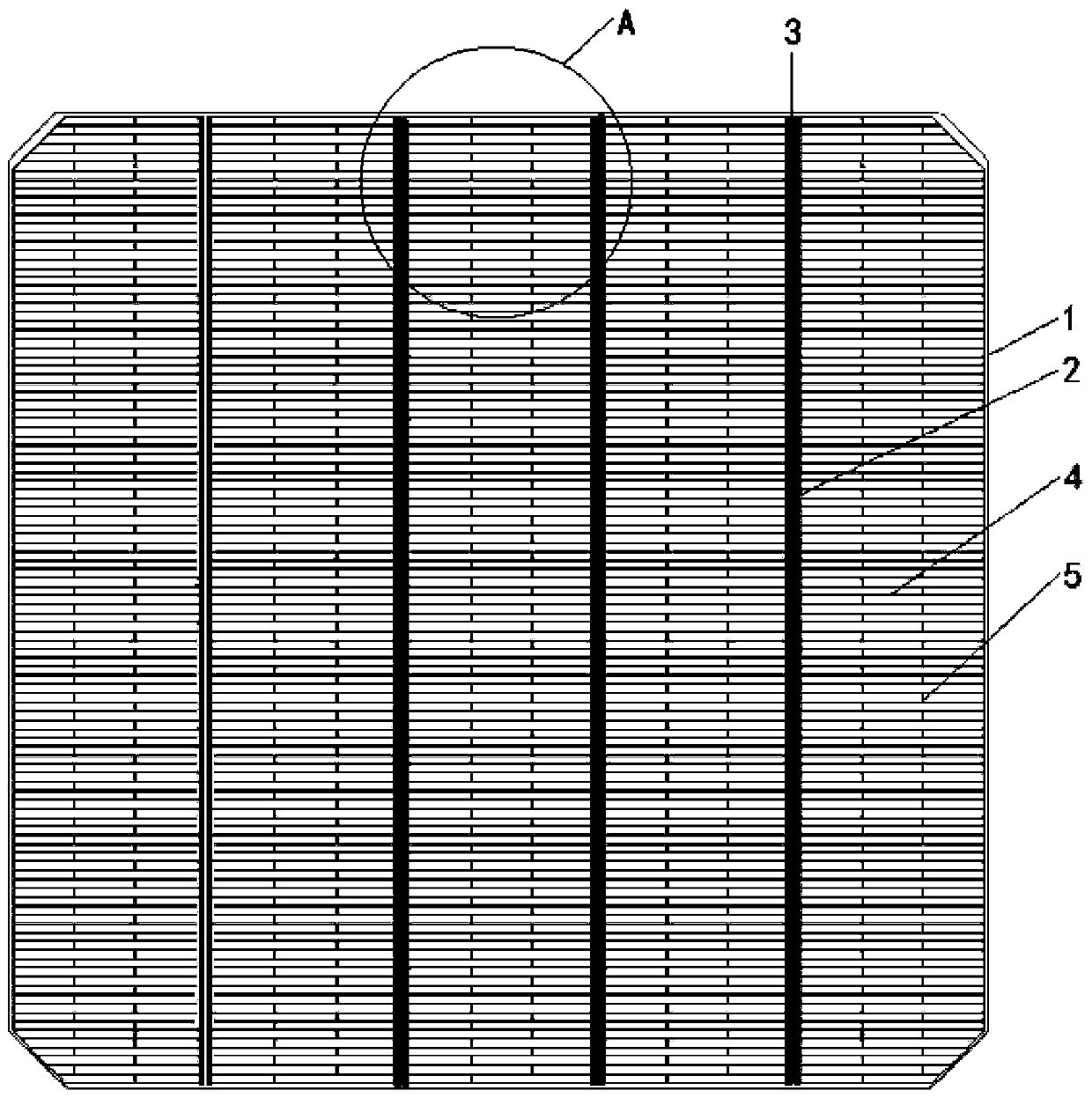

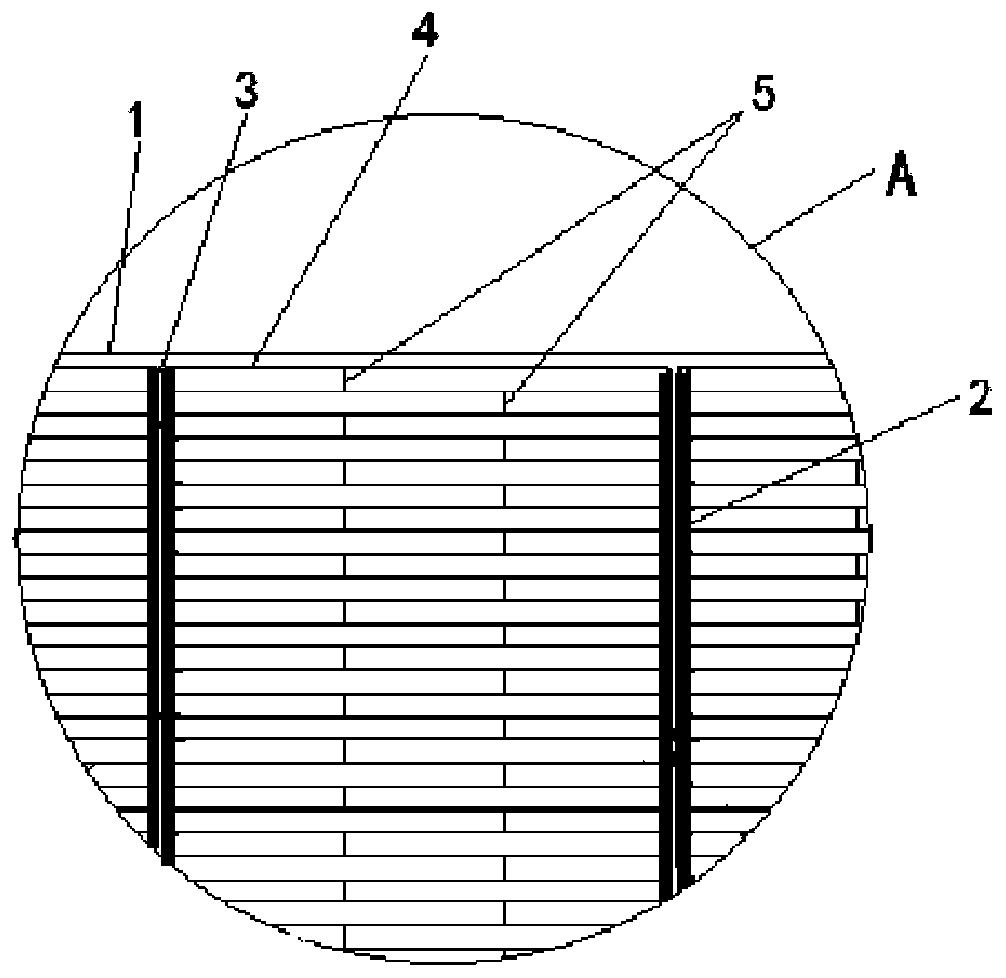

[0033] Such as Figure 1 to 2 As shown, this embodiment provides a mesh structure of a monocrystalline silicon solar cell, which includes a cell 1 with a number of front electrode regions on the front of the cell 1, and bus bars 2 between adjacent front electrode regions. The middle of the main grid line 2 is provided with a partition 3, the main grid line 2 is vertically connected with a number of sub-grid lines 4 located in the front electrode area, and both ends of the main grid line 2 are connected to the outermost sub-grid line 4, adjacent sub-grid lines 4 An anti-breakage grid line 5 is connected between the grid lines 4.

[0034] In this embodiment, the front side of the cell (that is, the positive electrode) adopts a partition structure, where it can generally be divided into 5 front electrode areas, and a partition area is provided in the middle of the main grid line to ensure the collection of photo-generated carriers and the assembly On the basis of welding reliability...

Embodiment 2

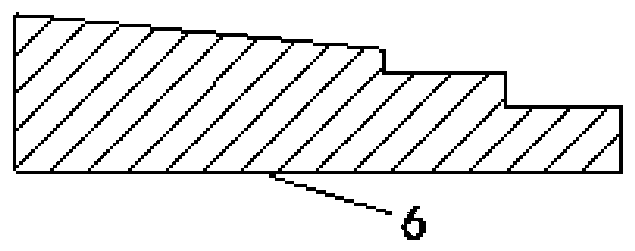

[0040] Such as Figure 1 to 4 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, a contact extension 6 is connected between the main gate line 2 and the auxiliary gate line 4, and the height of the contact extension 6 is greater than that of the auxiliary gate. The height of the wire 4, the contact extension 6 gradually narrows from the end close to the bus line 2 to the end far away from the bus line 2.

[0041] The length of the contact extension 6 is 0.3-0.7 mm, the width of the end of the contact extension 6 close to the bus line 2 is 0.6 mm, and the width of the end of the contact extension 6 away from the bus line 2 is 0.3 mm.

[0042] In this embodiment, the contact extension section can prevent the sub-gate line and the main gate line from being broken. In addition, when the collected conduction current in this area is concentrated to the maximum, the slurry of the contact extension section is superimposed in the height direction to ex...

Embodiment 3

[0044] Such as Figure 5 to 6 As shown, this embodiment is further optimized on the basis of embodiment 1. Specifically, the back of the battery sheet 1 is provided with a plurality of longitudinally arranged strip hollow areas 7 at positions corresponding to the front electrode area, where the strip hollow areas 7 Each column can be set up to 4 to form a 4X5 square array of strip hollow areas 7 as a whole. The strip hollow areas 7 are embedded with hollow electrodes 8, and both ends of the hollow electrodes 8 are connected vertically. Strip pins 9 arranged at equal intervals.

[0045] In this embodiment, a number of strip hollow areas are opened on the back of the cell, and hollow electrodes are nested and printed, and a number of strip pins are arranged on the edges of the hollow electrodes to ensure the basis for the overlap between the back of the cell (ie, the back electric field) and the hollow electrodes The upper part reduces the overlap area of the paste, reduces the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com