Motor monitoring method

A technology for motor monitoring and motor under test, applied in the direction of motor generator testing, measuring electricity, measuring devices, etc., can solve the problems of production and life impact, poor versatility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: a kind of motor monitoring method, comprises the following steps:

[0034] S1: Paste a unique identification code on the surface of the motor casing. The unique identification code is used as a kind of identity information of the motor and at the same time as a login port. The identification code can be in the form of barcode, two-dimensional code, NFC chip, etc. The parameters of the motor can be obtained by scanning the code of the device.

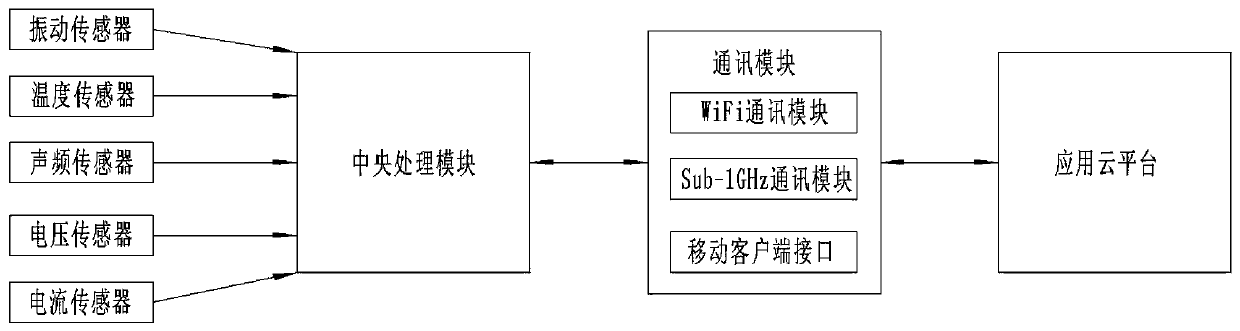

[0035] S2: Integrate the data acquisition module for the motor under test; embed the temperature sensor inside the stator coil of the motor, fix the vibration sensor and the audio frequency sensor inside the rotating bearing, and embed the voltage sensor and current transformer in the motor distribution box.

[0036] S3: Integrate the data acquisition module with the central processing module; integrate the data of the audio frequency sensor, vibration sensor, temperature sensor, voltage sensor and current sensor wit...

Embodiment 2

[0041] Embodiment 2: a kind of motor monitoring method, comprises the following steps:

[0042] S1: Paste the unique identification code on the surface of the motor casing. The unique identification code is used as a kind of identity information of the motor and at the same time as a login port. You can log in and enter the relevant parameters of the motor by scanning the code with the relevant electronic equipment and save the relevant parameters. Parameter information; create a motor list; the second scan can automatically connect to the motor list.

[0043] S2: Integrate the data acquisition module for the motor under test; fix the audio frequency sensor, vibration sensor and temperature sensor on the surface of the motor shell, and embed the voltage sensor and current sensor in the motor distribution box.

[0044] S3: Integrate the data acquisition module with the central processing module; integrate the data of the audio frequency sensor, vibration sensor, temperature sen...

Embodiment 3

[0049] Embodiment 3: A motor monitoring method, which is suitable for quick inspection or fixed inspection when a database has been established for a certain type of motor in Embodiment 1 and Embodiment 2, including the following steps:

[0050] S1: Paste the unique identification code on the surface of the motor casing. The unique identification code is used as a kind of identity information of the motor and at the same time as a login port. You can log in and enter the relevant parameters of the motor by scanning the code with the relevant electronic equipment and save the relevant parameters. Parameter information, build a motor list; the second scan can be automatically connected to the motor list.

[0051] S2: Integrate the data acquisition module for the motor under test; fix the audio frequency sensor, vibration sensor and temperature sensor on the surface of the motor shell.

[0052] S3: Integrate the data acquisition module with the central processing module; integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com