Automatic high-flux SPR detector

A detector and high-throughput technology, applied in the direction of chemical instruments and methods, instruments, measuring devices, etc., can solve the problems of high cost, low flux, and difficulty in distinguishing non-specific adsorption, and achieve long service life, easy replacement, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

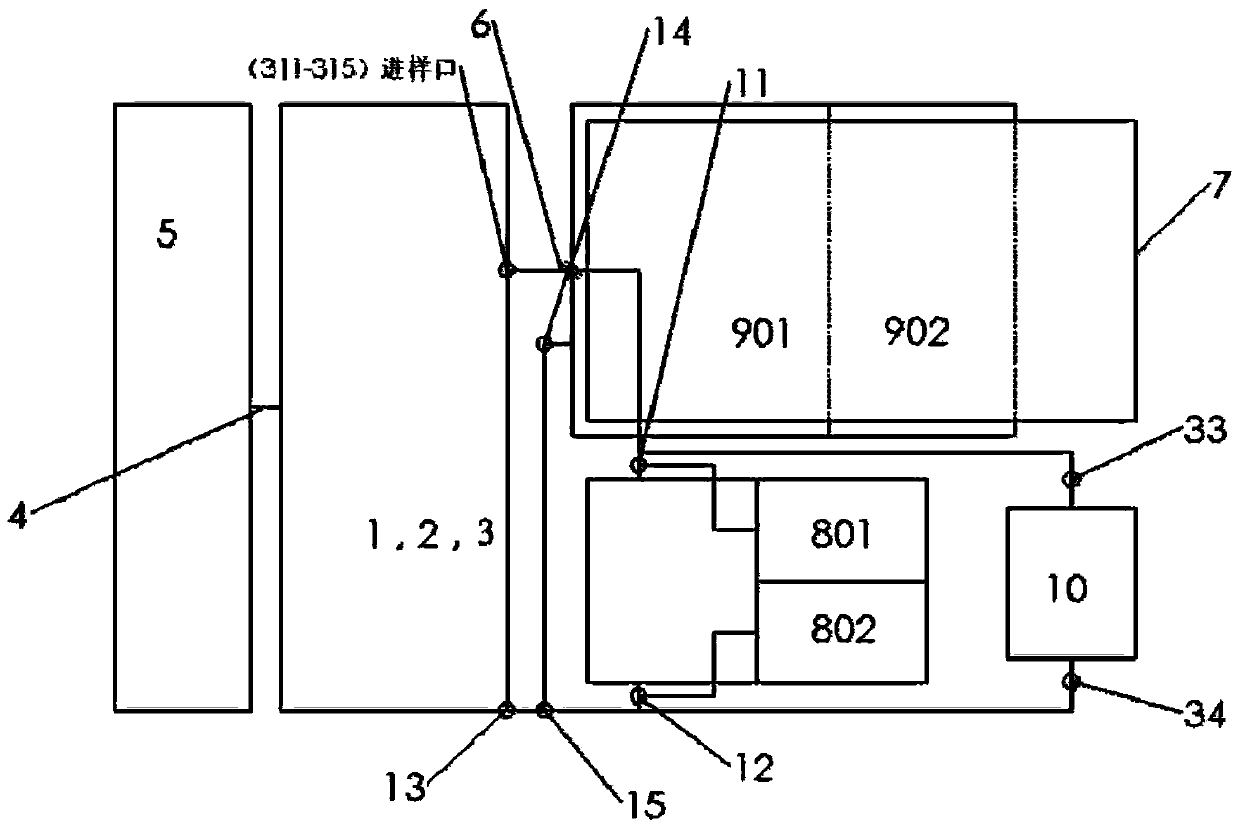

[0030] see figure 1 as well as Figure 9 , the present invention provides an automatic high-throughput SPR detector, comprising a laser 1, an optical group 2 for exciting SPR, an SPR biosensor 3, a detection signal collector 4, a control and analysis unit 5, a flow pipeline 6, and an automatic sampling Device 7 and automatic cleaning device 8, automatic waste collection device 9, laser 1, optical group 2 for exciting SPR, SPR biosensor 3 are connected to control and analysis unit 5 through detection signal collector 4, and flow pipe 6 is connected to SPR biosensor 3 , Automatic sampling device 7 and automatic cleaning device 8.

[0031]In this embodiment, the light group 2 for exciting SPR includes a beam expander 201, a collimator 202, ...

Embodiment 2

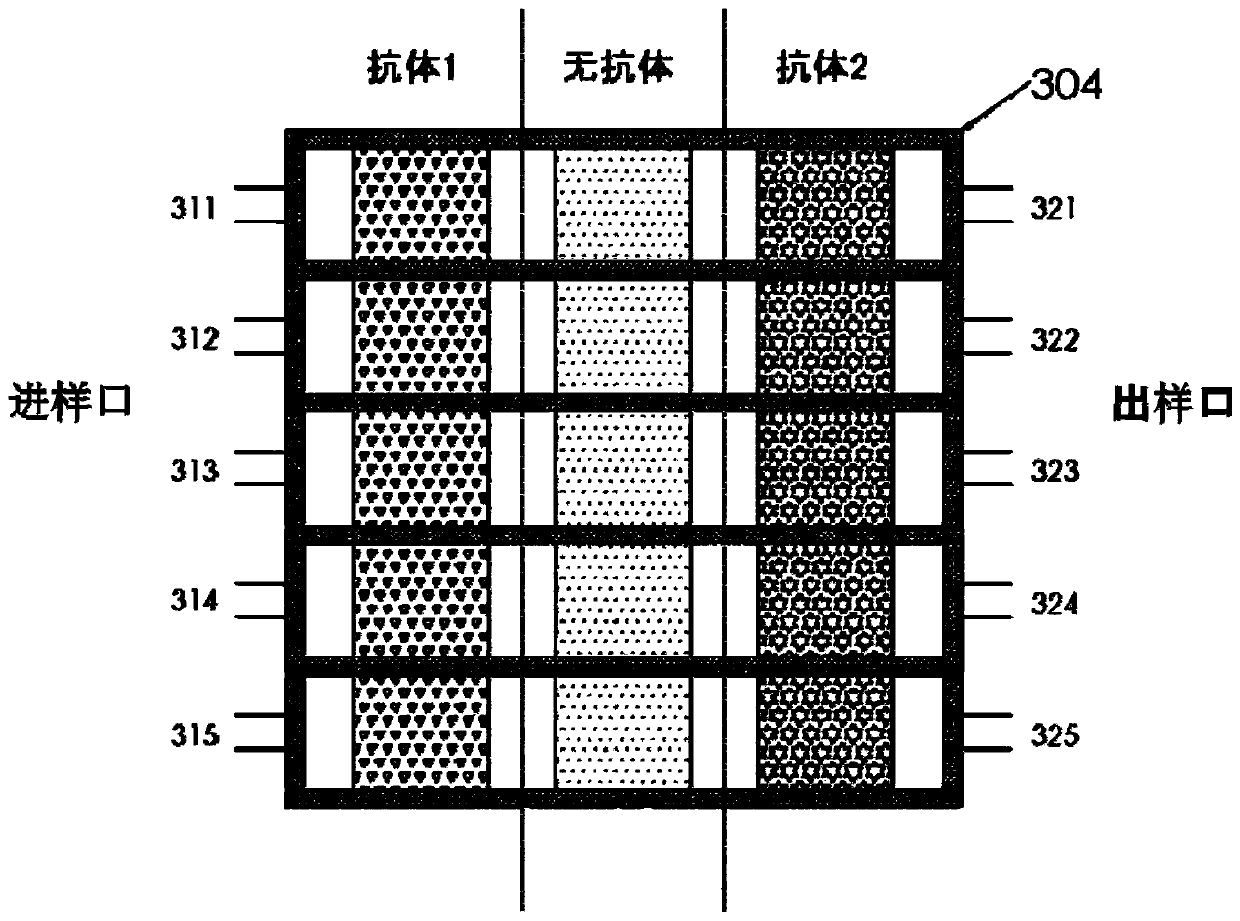

[0039] The biochip 302 is arranged in an array of at least 5 rows*3 columns, each row is a channel, and a sample is detected, and the immobilized biosensitive molecules in each column are antibody 1, no antibody, and antibody 2 from left to right. The column without antibody is used as a reference to eliminate the influence of the difference in refractive index of different samples, or other factors such as temperature on the result analysis. The biochip 302 includes a base layer and a coating layer arranged on the surface of the base layer. The biochip 302 also has a flow cell 302, at least five sample inlets, and at least five sample outlets. The sample inlets correspond to the sample outlets one by one. The sampling port is connected with the sampling needle 20 through the flow hose 24 . The base layer is a silicon chip, and the silicon chip is coated with a gold film or a composite film, and the carboxylated dextran layer is fixed by covalent coupling on the silicon chip c...

Embodiment 3

[0041] The sampling needle 20 is much larger than the flow pipe 6, and can produce a large enough opening after piercing, so as to facilitate the dumping of waste liquid in the later stage. An easy-to-replace rubber gasket 17 is arranged above the sampling needle 20, and the cleaning notch matches the rubber gasket to ensure the tightness between the sampling port and the sampler interface, and the gas siphon unit can work normally to complete the sample injection. The rubber gasket 17 is an annular ring whose lower diameter is slightly smaller than that of the upper part. When the three-dimensional motion mechanical arm 25 moves down in the Z direction and squeezes the rubber gasket 17, the elasticity of the rubber is used to make the interface well sealed; Matching, the structure is the same as the thermos cup lid. When the rubber sealing gasket 17 is aging, it is easy to replace, maintain good sealing performance, and prolong the service life of the whole system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com