Prefabricated rail top air duct for metro station and construction method of air duct

A technology for rail top air ducts and subway stations, which is applied in mine/tunnel ventilation, earthwork drilling, mining equipment, etc. It can solve problems such as difficult pouring and compaction, affecting the construction period of the whole line, and difficult construction, so as to facilitate transportation and hoisting , save the amount of concrete, no need for post-maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

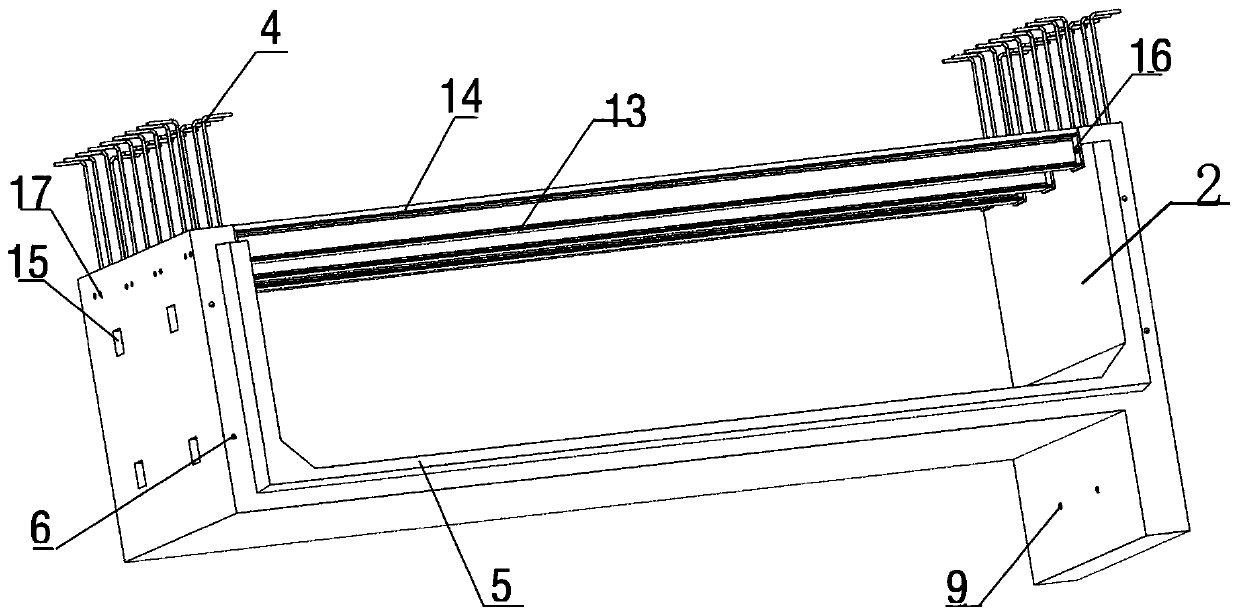

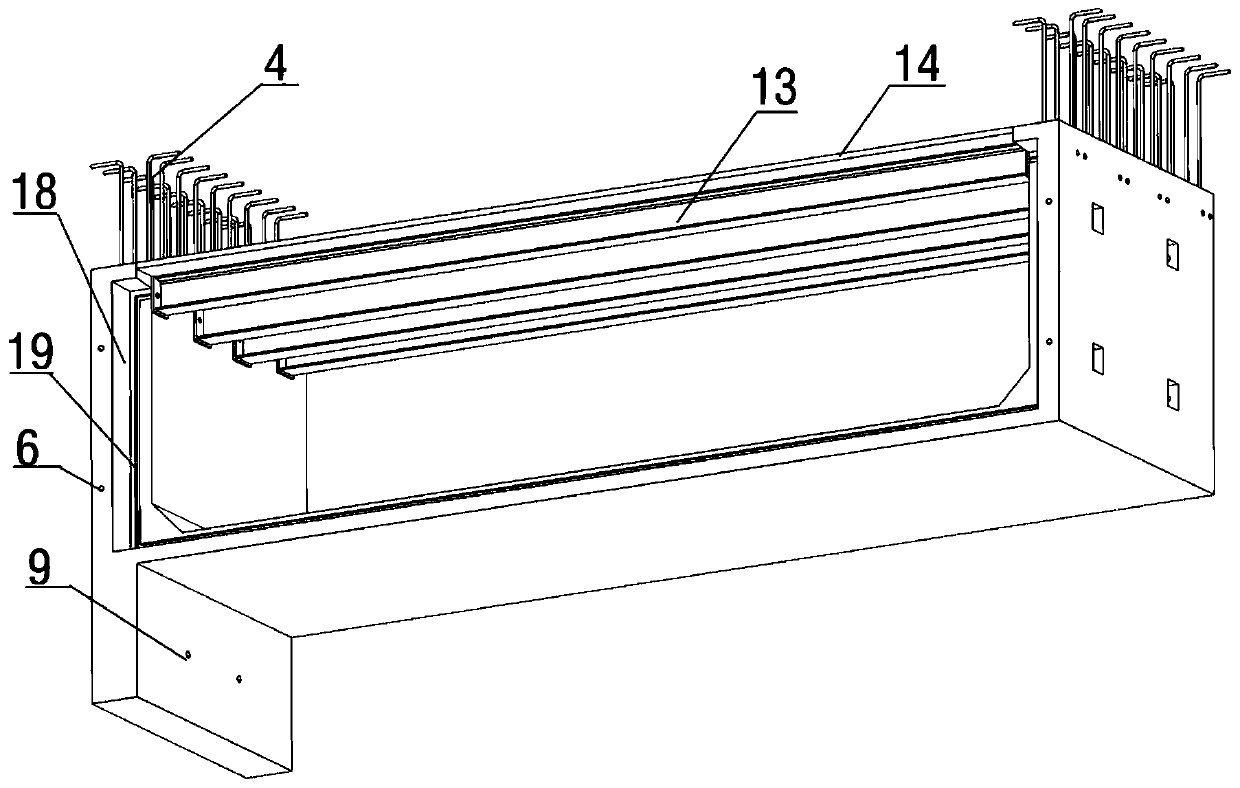

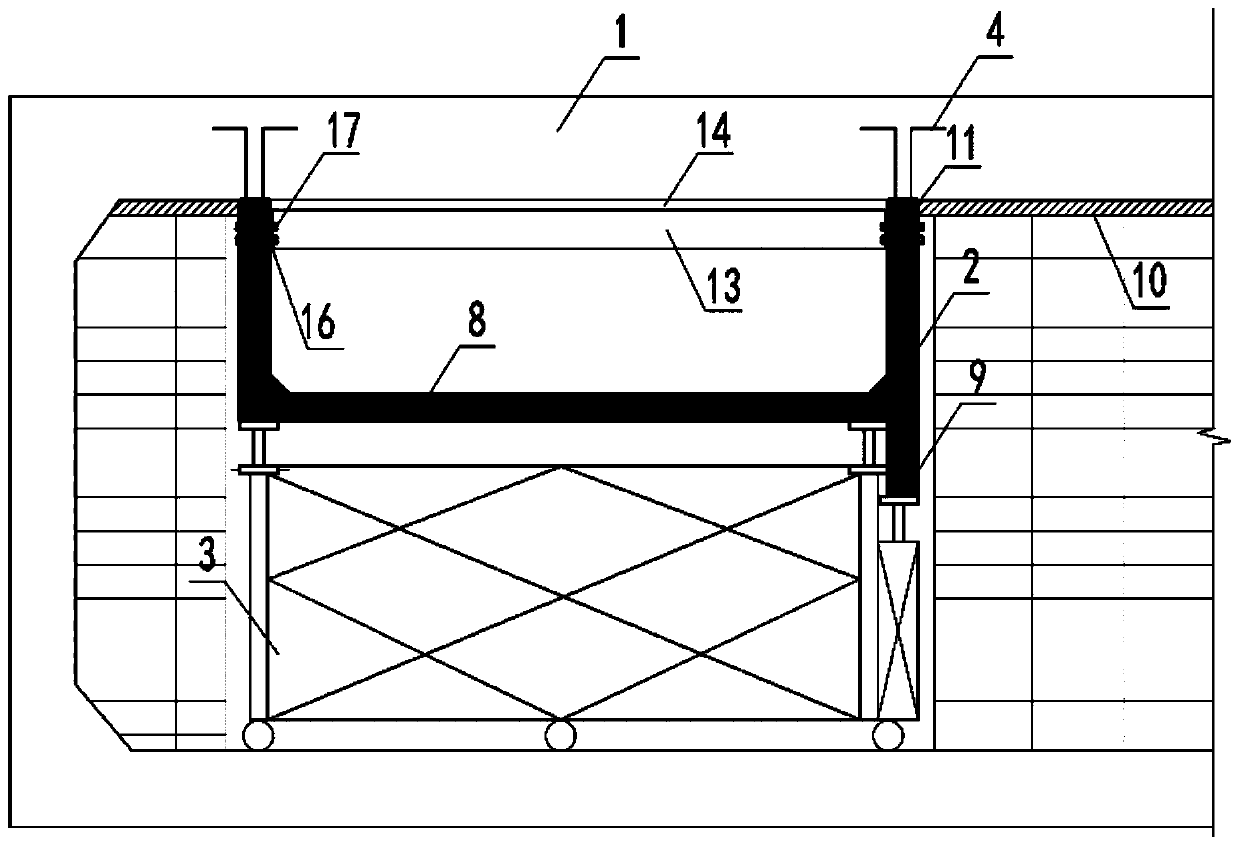

[0071] figure 1 with figure 2 It is a front view and a rear view of a rail top air duct of the present invention. The prefabricated rail roof air duct includes a U-shaped air duct 2, the inner bottom plate of the air duct and the two side plates are integrally formed, and the top of the air duct side plate is reserved with a steel bar 4, and the steel bar can be bent into an "L" shape or internal Hollow rebar connectors. The air duct port is composed of the air duct bottom plate and the two side plates, and has two end faces. One end of the air duct port has a protruding structure 5 extending outward, and the other end of the air duct port is provided with a first groove 18 corresponding to the protruding structure 5, so that the protruding structure 5 can be inserted into the first The groove 18 is also provided with a "mouth"-shaped second groove 19 inside the first groove 18 for filling the compound rubber sealing strip.

[0072] One end protruding from the side plate ...

Embodiment 2

[0090] Such as Image 6 Shown is a schematic structural view of the second embodiment of the present invention. The prefabricated rail roof air duct includes side panels, bottom panels and partition walls 20, and the side panels, bottom panels and partition walls 20 are provided with reinforcement bars 4, which can be beard tendons in an "L" shape after bending or The inner hollow steel bar connector, the side plate, the bottom plate and the partition wall 20 are pierced with section steel 13, and the section steel 13 is in an inverted "T" shape, and a wooden formwork 14 is arranged on the lower surface of the section steel 13. The long side of the bottom plate is divided into two parts by a partition.

[0091] The rail top air duct includes at least two, and the end formed by the bottom plate and the side plate is provided with a first groove 18, and the first groove 18 is filled with a composite rubber sealing strip. A pre-embedded steel box 21 is pre-embedded at one end c...

Embodiment 3

[0108] In Embodiment 3 of the present invention, the "U-shaped" or "W-shaped" rail top air duct as in Embodiment 1 or Embodiment 2 is used, and the steel bar connector is embedded in the side plate of the rail top air duct in this embodiment , the upper surface of the steel bar connector is flush with the upper surface of the side plate of the rail top air duct, and the connection mode between other rail top air ducts is as described in Embodiment 1 or Embodiment 2, using flat end surface connection or receiving type concave-convex The connection method of the interface.

[0109] Embodiment 3 of the present invention is a method for simultaneous construction of a prefabricated rail top air duct and a prefabricated laminated mid-slab or rear-hanging construction with a cast-in-place mid-slab, comprising the following steps:

[0110] (1) Make a "U"-shaped rail top air duct, and pre-embed steel bar connectors in the two side panels of the rail top air duct, and the upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com