Production process of double-faced woolen product

A production process, false double-sided technology, applied in fabric surface trimming, weaving, yarn and other directions, can solve the problem of unsightly appearance and achieve the effect of rich colors and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of false double-sided cloth production technology provided by the invention comprises the following steps:

[0036] a. Weaving: use a loom to weave double-faced cloth, the selected warp yarns include warp yarns A and warp yarns B, the warp yarns A are slubbed yarns containing wool, and the warp yarns B are double-strand polyester threads; The weft yarn includes a weft yarn A and a weft yarn B, the weft yarn A is a slubbed yarn containing wool, and the weft yarn B is a ply of two strands of woolen yarn of different colors and a single strand of polyester filament of a third color Yarn; wherein two strands of slubbed yarns of different colors and a single strand of third-color polyester filaments of weft yarn B are straightened out into the drum through a wire device, wherein two strands of slub yarns of different colors are cross-wound on the third-color and On polyester filament;

[0037] b. Steaming: carry out steaming treatment on the woven double-faced wool; ...

Embodiment 2

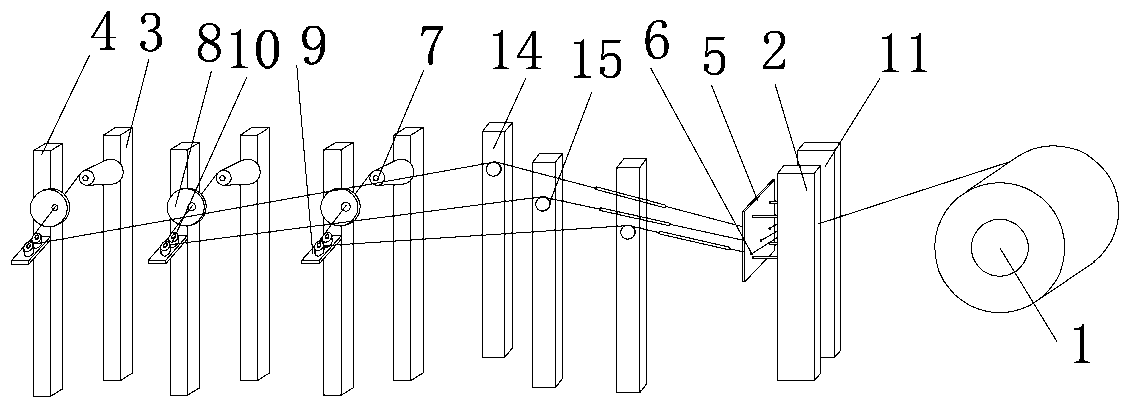

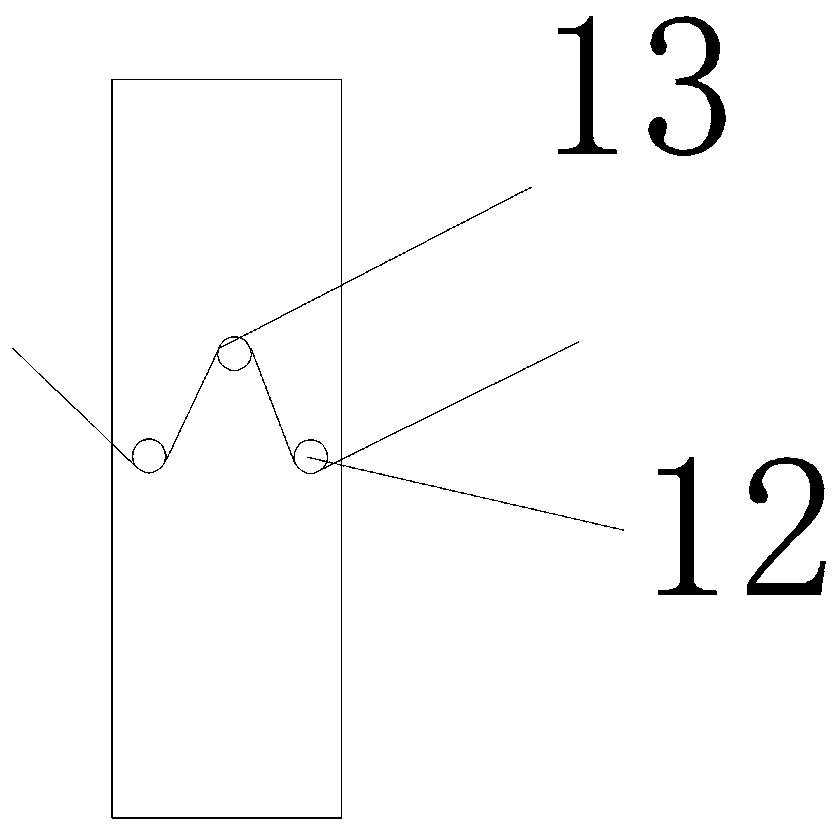

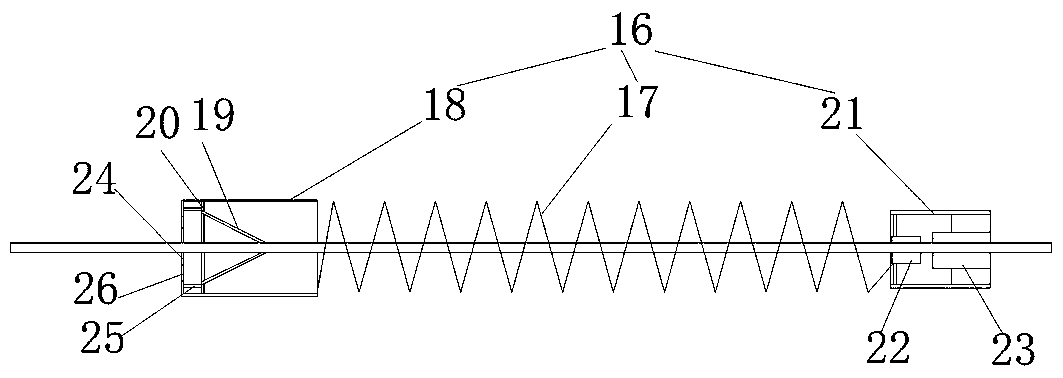

[0047] The invention also discloses a wire device, which includes a drum 1 driven by a driving motor, a tensioning device 2, three first fixing frames 3 and three second fixing frames 4; The front end of the tightening device is equipped with a wire assembly 5, and the wire assembly is provided with a plurality of parallel introduction holes 6 that are convenient for the yarn to pass through and are at the same level; The rod is used to install the yarn bobbin; the second fixed frame is equipped with a fixed disk 8, and the fixed disk is equipped with a threading hole; the middle part of the second fixed frame is equipped with a side plate 9, and the side plate is equipped with a guide wheel Group 10, the yarn on the yarn drum passes through the threading hole through the guide wheel group, the wire assembly and the tensioning device, and then is wound on the drum; the tensioning device includes a pair of fixing seats 11; a pair of the A pair of bottom rods 12 at the same leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com