Hydrogen absorption material for electronic packaging and preparation method thereof

A hydrogen-absorbing material and electronic packaging technology, applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as failure of hydrogen content exceeding the standard of sealed electronic device components, reduced solderability, increased production cycle, etc. , to achieve good hydrogen absorption capacity, high production efficiency and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

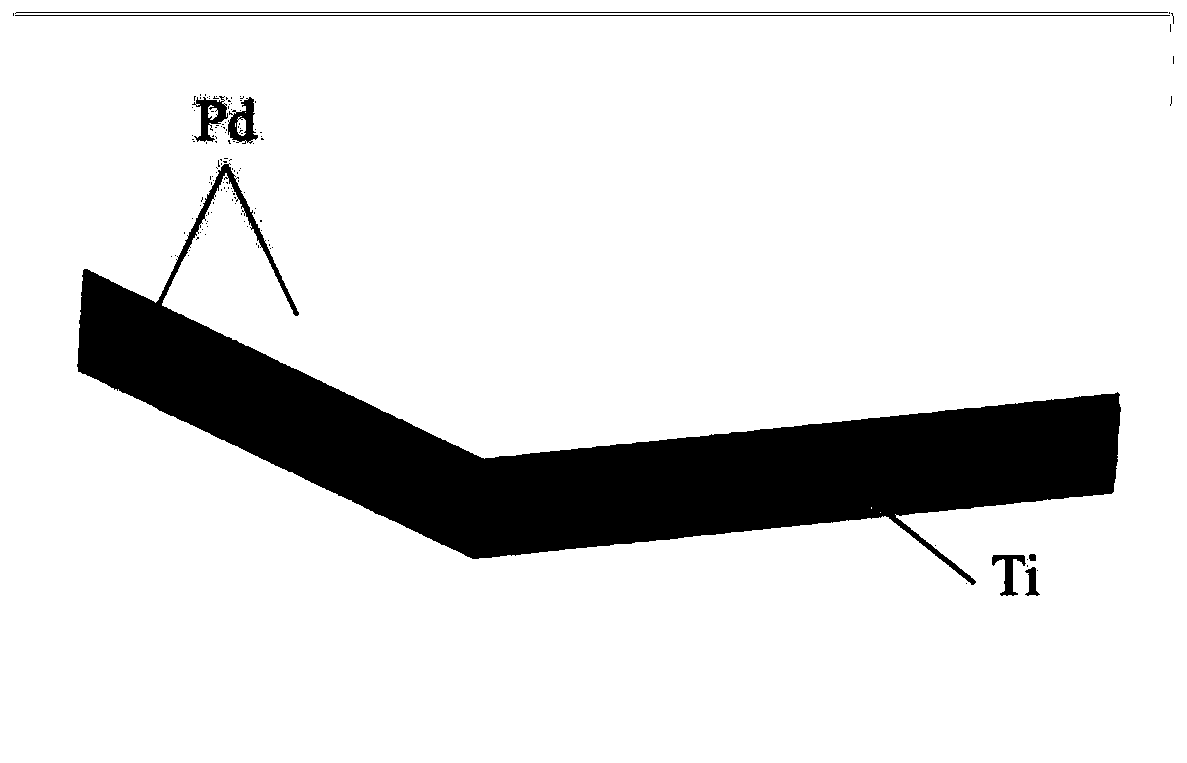

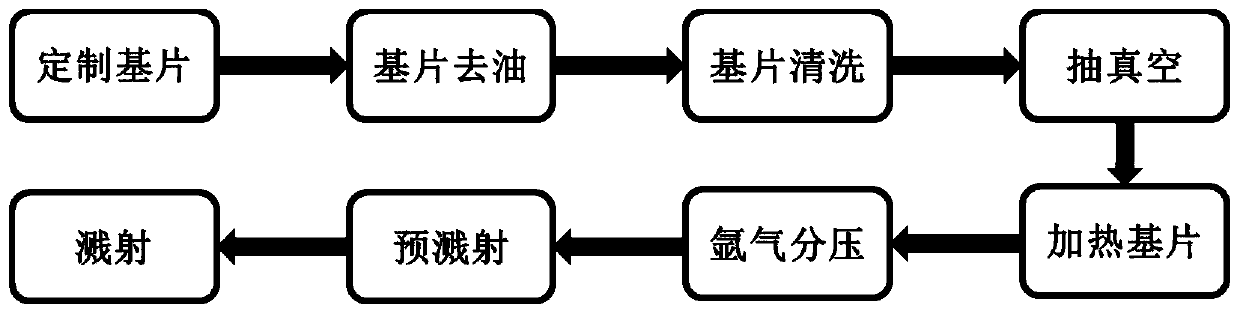

[0049] A hydrogen-absorbing material for electronic packaging, with a structure such as figure 1 shown. A titanium sheet with a purity greater than 99% is used as the sputtering substrate with a thickness of 0.2 mm. The thickness of the sputtered palladium layer is Prepare according to the above-mentioned preparation method, and the vacuum needs to be controlled at 2×10 during sputtering. -4 Below Pa.

[0050] The thickness of the Ti base material formulated by the present invention, the thickness of the Pd catalytic layer, and the sputtering process parameters are optimal parameters that comprehensively consider efficiency and effect obtained after many tests, and can ensure that the hydrogen in the atmosphere inside the sealed electronic device assembly is effectively absorbed. absorb.

[0051] The hydrogen absorbing material of the present invention is compared with common hydrogen control methods for hydrogen removal effect. The selected experimental Kovar packaging s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com