A method for preparing high-purity nano-silicon

A nano-silicon and nano-silicon dioxide technology, which is applied in the field of preparing high-purity nano-silicon, can solve the problems of low product purity, amorphous product shape, and uneven particle distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

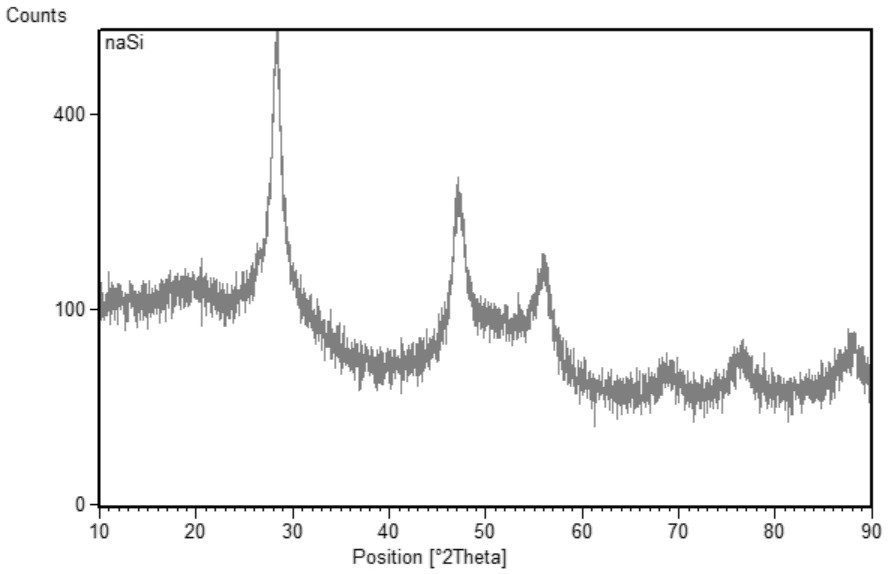

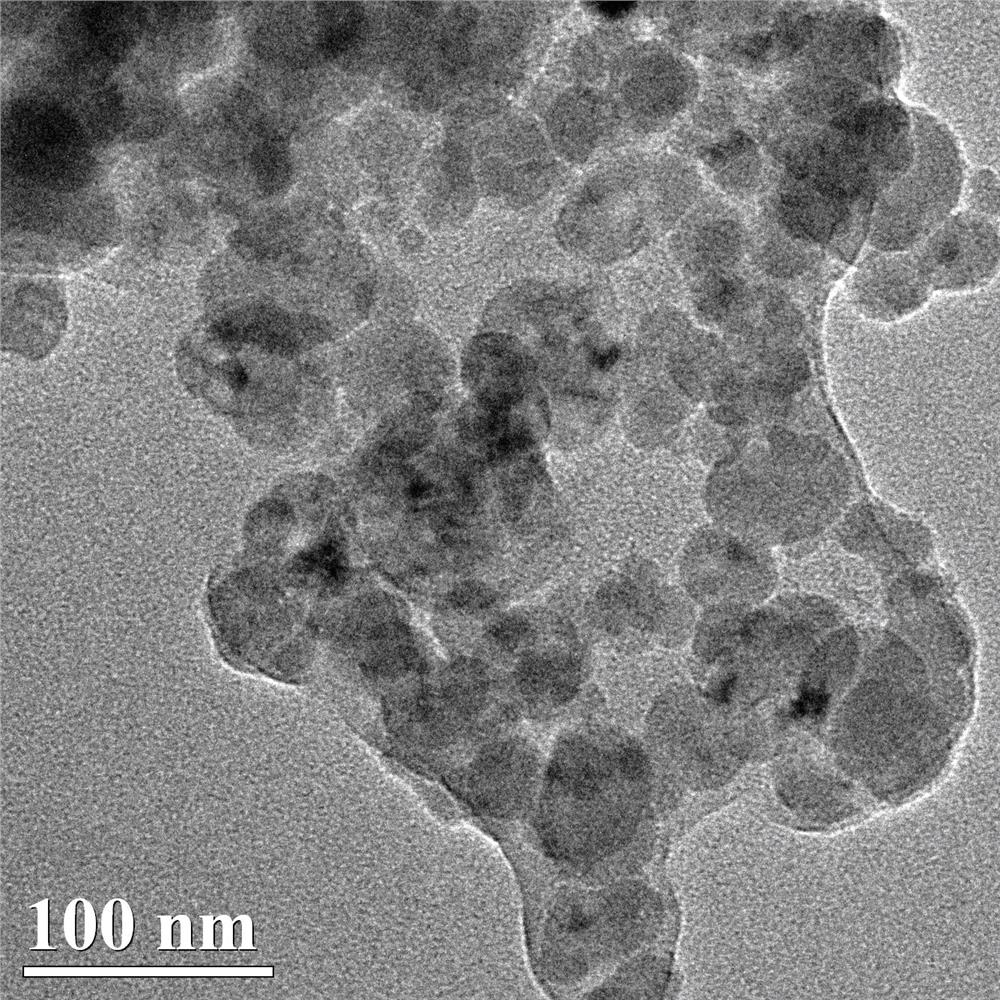

[0024] Mix ethyl orthosilicate with ethanol and deionized water in a beaker, the mixing mass ratio is 1:2:3, put it into a water bath for water bath stirring, the water bath temperature is 40°C, and the stirring time is 4h. After dispersing evenly, add ammonia water into the beaker, the mass ratio of ammonia water to tetraethyl orthosilicate is 1:1, continue to stir for 5 hours, finally wash with ethanol ultrasonically, and dry in an oven. The obtained product was mixed evenly with magnesium hydride, and reduced in a box furnace under a nitrogen atmosphere, kept at 300°C for 2 hours, continued to heat up to 800°C, kept at 3h, and the heating rate was 2°C / min. After the reaction is cooled, the residual nano-silica and magnesium oxide are washed away with hydrofluoric acid, then cleaned and filtered with ultra-pure water until neutral, and finally vacuum-dried to obtain nano-silicon. The XRD figure, TEM figure of gained nano-silicon are respectively as follows figure 1 , figu...

Embodiment 2

[0026] Take a certain amount of tetraethyl orthosilicate and mix it with propanol and deionized water in a beaker, the mixing mass ratio is 1:2:2, put it into a water bath for water bath stirring, the water bath temperature is 50°C, and the stirring time is 1h. After dispersing evenly, add ammonia water into the beaker, the mass ratio of ammonia water to tetraethyl orthosilicate is 0.8:1, continue to stir for 3 hours, finally wash with ethanol ultrasonically, and dry in an oven. The obtained product and aluminum hydride were subjected to hydrogen carbonization reduction in a drum furnace, kept at 500°C for 2 hours, and continued to heat up to 1000°C for 4 hours at a heating rate of 10°C / min. After the reaction is cooled, the remaining nano silicon dioxide and aluminum oxide are washed away with hydrofluoric acid, then cleaned and filtered with ultrapure water until neutral, and finally vacuum dried to obtain nano silicon.

Embodiment 3

[0028] Mix tetraethyl orthosilicate, propanol and deionized water at a mass ratio of 1:2:4, put them into a water bath for water bath stirring, the temperature of the water bath is 70°C, and the stirring time is 1h. After dispersing evenly, add ammonia water into the beaker, the mass ratio of ammonia water to tetraethyl orthosilicate is 0.5:1, continue to stir for 2 hours, finally wash with ethanol ultrasonically, and dry in an oven. The obtained product and alkaline earth metal hydrides other than Be were subjected to hydrogen carbonization reduction in a drum furnace, kept at 400°C for 2 hours, continued to heat up to 1300°C, kept at 6 hours, and the heating rate was 6°C / min. After the reaction is cooled, the residual nano-silicon dioxide and metal oxides are washed away with hydrofluoric acid, then cleaned and filtered with ultra-pure water until neutral, and finally vacuum-dried to obtain nano-silicon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com