Auxiliary device for hoisting maintenance of injection mold

An injection mold and auxiliary device technology, which is applied in the field of auxiliary devices for the lifting and maintenance of injection molds, can solve the problems of high probability of warping, offset of the center of gravity of the placing table, insufficient stability, etc., and achieves the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

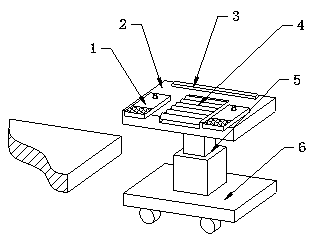

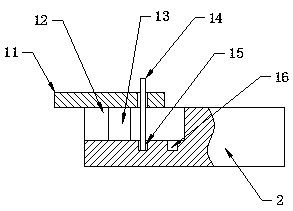

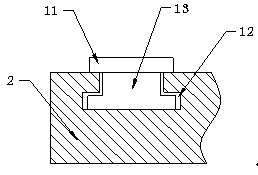

[0019] see Figure 1-Figure 3 , the present invention provides a technical solution: an auxiliary device for lifting and maintaining injection molds, including an anti-warping component 1, a placing table 2, a limit bar 3, a round roller 4, a central column 5 and a bottom plate 6, and the central column 5 is fixed On the upper end face of the base plate 6, the placing table 2 is fixed on the upper end face of the central column 5, the limit bar 3 is fixed on the rear side of the upper end face of the placing table 2, and the round roller 4 is installed on the middle position of the upper end face of the placing table 2 and the round roller 4 is arranged at the limit. On the front side of the bit bar 3 , the anti-warping component 1 is installed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com