Waste filter bag cleaning and recycling device and method

A technology of recycling equipment and recycling methods, which is applied in the direction of plastic recycling and recycling technology, can solve the problems that affect the recycling of polytetrafluoroethylene filter bags, and the surface stains cannot be cleaned thoroughly, so as to prolong the storage time and reduce the price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

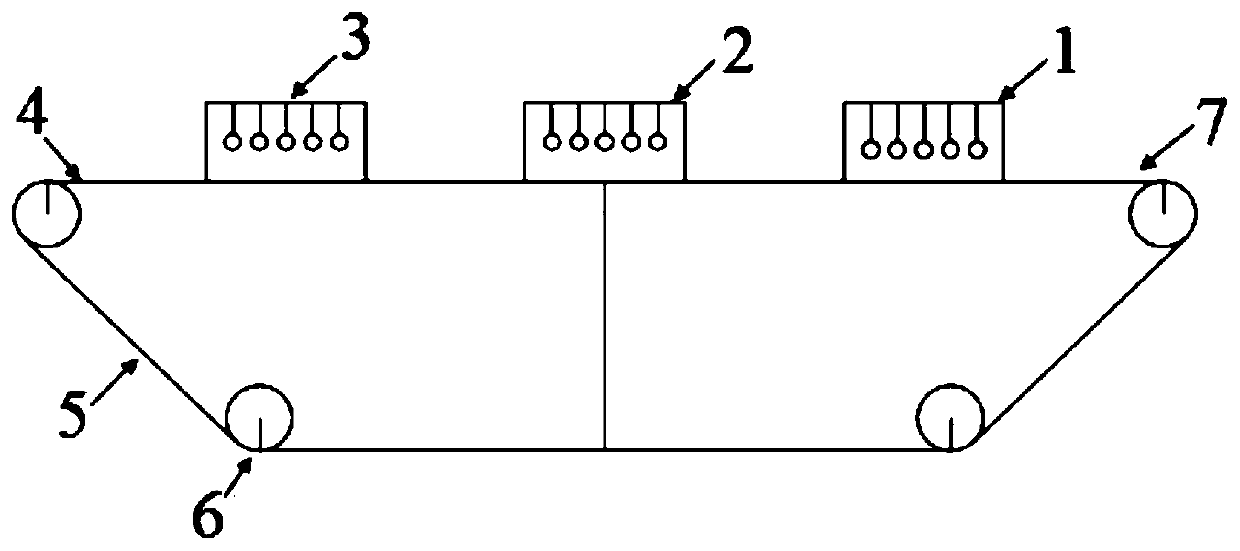

[0045] to combine figure 1 , a cleaning and recovery equipment for waste filter bags in this implementation, including a conveyor belt 5 and a drum 6, the drum 6 drives the conveyor belt 5 to move; Cargo area 7, cleaning area 1, spraying area 2, drying area 3 and unloading area 4. Wherein, the cleaning area 1 has a length of 2m and a width of 1.2m. The spray area 2 has a length of 2m and a width of 1m. The conveying speed of the conveyor belt 5 can be 0.8-1.2m / min, which is set to 0.8m / min in this embodiment.

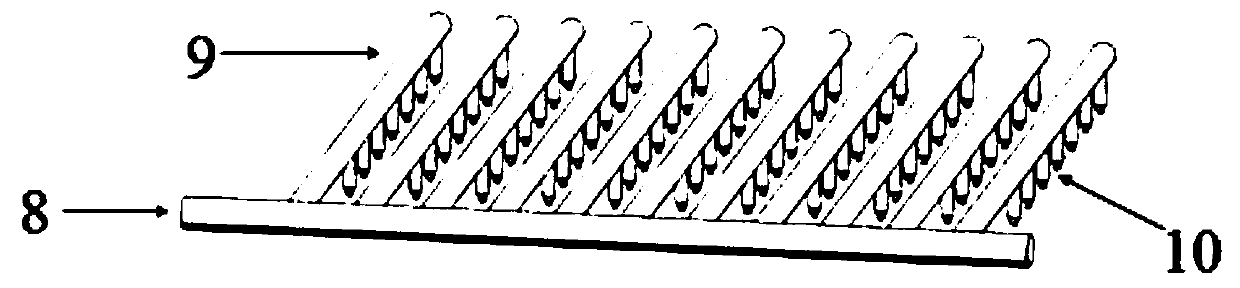

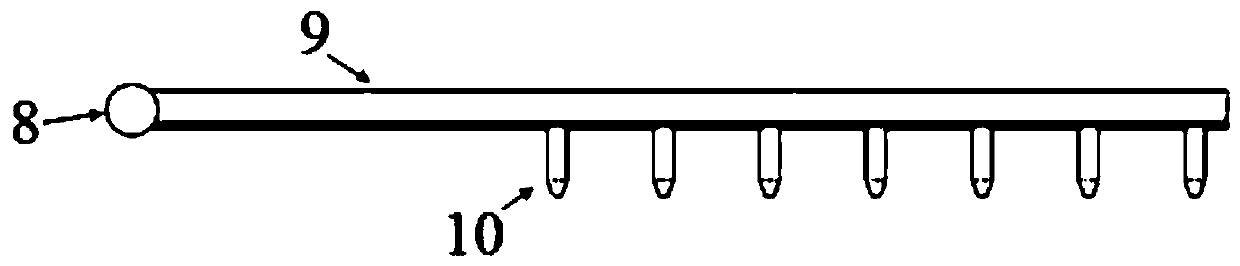

[0046] to combine figure 2 The inside of the cleaning area 1 and the spraying area 2 is provided with a cleaning assembly, the cleaning assembly includes a water supply main pipe 8 and a water supply branch pipe 9, the water supply branch pipe 9 is connected with the water supply main pipe 8, and the water supply branch pipe 9 is along the water supply main pipe 8 There are many roots arranged side by side in the length direction. Specifically in this embodiment, ...

Embodiment 2

[0050] The cleaning and recovery equipment of a waste polytetrafluoroethylene microporous membrane filter bag in this implementation is basically the same in design as that of Example 1, the difference is that the transmission speed of the conveyor belt 5 is set to 1.2m / min in this example. Set the nozzle 10 of the cleaning area 1 at a distance of 500 mm from the filter bag, and the pressure of the nozzle 10 is 0.5 MPa. The nozzle 10 of the spraying area 2 is 500mm away from the filter bag, and the pressure of the nozzle 10 is 3MPa. The distance between the tuyere 11 of the drying zone 3 and the filter bag is 500mm, and the wind speed of the tuyere 11 is 10m / s.

Embodiment 3

[0052] The cleaning and recovery equipment of a waste polytetrafluoroethylene microporous membrane filter bag in this implementation is basically the same in design as in Example 1, the difference is that in this example, the conveying speed of the conveyor belt 5 is set to 1.0 m / min. Set the nozzle 10 of the cleaning area 1 at a distance of 400 mm from the filter bag, and the pressure of the nozzle 10 is 0.4 MPa. The nozzle 10 of the spraying area 2 is 400 mm away from the filter bag, and the pressure of the nozzle 10 is 2 MPa. The distance between the tuyere 11 of the drying zone 3 and the filter bag is 400mm, and the wind speed of the tuyere 11 is 7m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com