A combined forming method for preparing high-strength ultra-thin strips

An ultra-thin strip and high-strength technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of high cost and reduce production cost, achieve good tensile and compressive strength, optimize processing technology, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

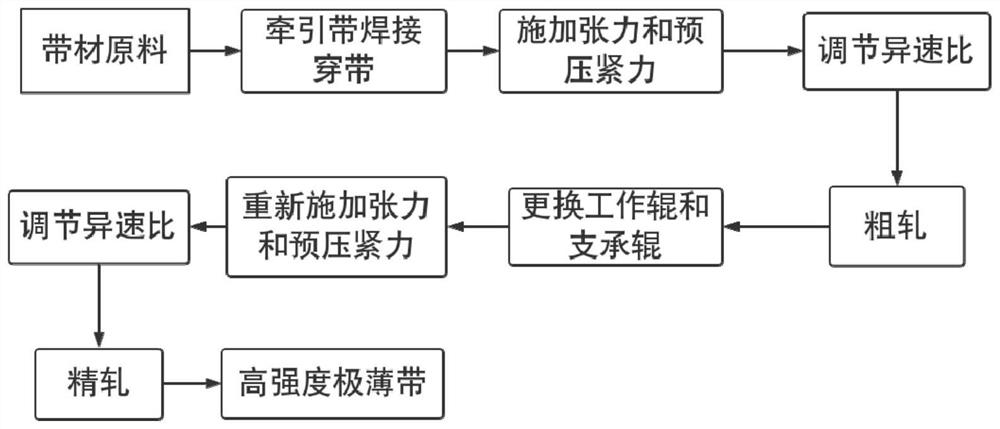

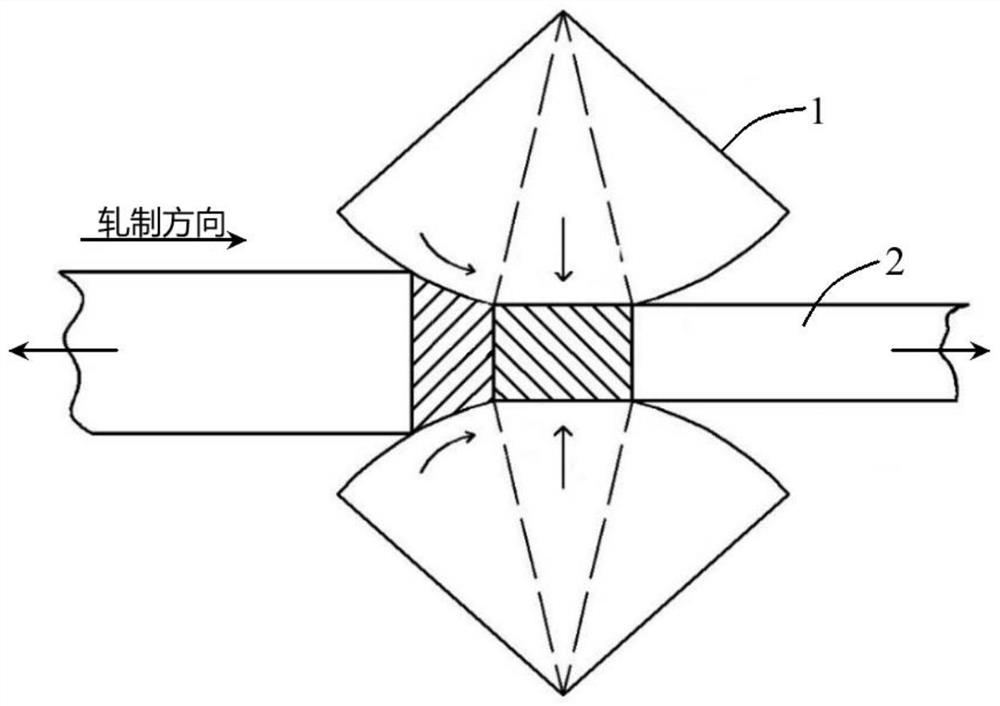

[0034] combine figure 1 , a combined forming method for preparing high-strength ultra-thin strips in this embodiment, using asynchronous + tension + pre-compression force combined forming process, after rough rolling and finishing rolling, 304 stainless steel strips with a thickness of 5mm can be rolled A very thin strip of high-strength stainless steel with a thickness of 50 μm. The specific implementation steps are:

[0035] Step 1. Weld and fix the 304 stainless steel strip with a length of 350 mm and a thickness of 5 mm with the traction belt, and then thread the fixed stainless steel strip on a four-roll asynchronous cold rolling mill.

[0036] Step 2. Apply front and rear tension to the stainless steel strip after threading is completed. The tension value is 50% of the yield strength of the 304 stainless steel strip with equal thickness. After the front and rear tension is applied, apply a pre-compression force. 90t.

[0037] Step 3, setting the roll speed of the work...

Embodiment 2

[0047] A combined forming method for preparing high-strength ultra-thin strips in this embodiment involves rolling a 201 stainless steel strip with a thickness of 2 mm into a high-strength ultra-thin stainless steel strip with a thickness of 20 μm. The rolling process is basically the same as in Example 1, except that The difference is that the parameters of the rolling process are different, as follows:

[0048] Step 1. Weld and fix the 201 stainless steel strip with a length of 400 mm and a thickness of 2 mm to the traction belt, and then thread the fixed stainless steel strip on a four-roll asynchronous cold rolling mill.

[0049] Step 2. Apply front and rear tension to the stainless steel strip after threading is completed. The tension value is 55% of the yield strength of the 201 stainless steel strip with equal thickness. After the front and rear tension is applied, apply a pre-compression force. 70t.

[0050] Step 3, setting the roll speed of the work rolls, performing...

Embodiment 3

[0054] A combined forming method for preparing a high-strength ultra-thin strip in this embodiment is to roll a 430 stainless steel strip with a thickness of 1.4 mm into a high-strength stainless steel ultra-thin strip with a thickness of 10 μm. The rolling process is basically the same as in Example 1. The difference is that the parameters of the rolling process are different, as follows:

[0055] Step 1. Weld and fix the 430 stainless steel strip with a length of 500 mm and a thickness of 1.4 mm and the traction belt, and then thread the fixed stainless steel strip on a four-roll asynchronous cold rolling mill.

[0056] Step 2. Apply front and rear tension to the stainless steel strip after threading is completed. The tension value is 53% of the yield strength of the 430 stainless steel strip with equal thickness. After the front and rear tension is applied, apply a pre-compression force. 62t.

[0057] Step 3, setting the roll speed of the work rolls, performing multi-pass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com