A kind of beneficiation method of magnetite

A beneficiation method and magnetite technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of high water content, powder content, impurity and iron content, etc., to reduce failure rate and improve metal recovery rate and improve the effect of sorting indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

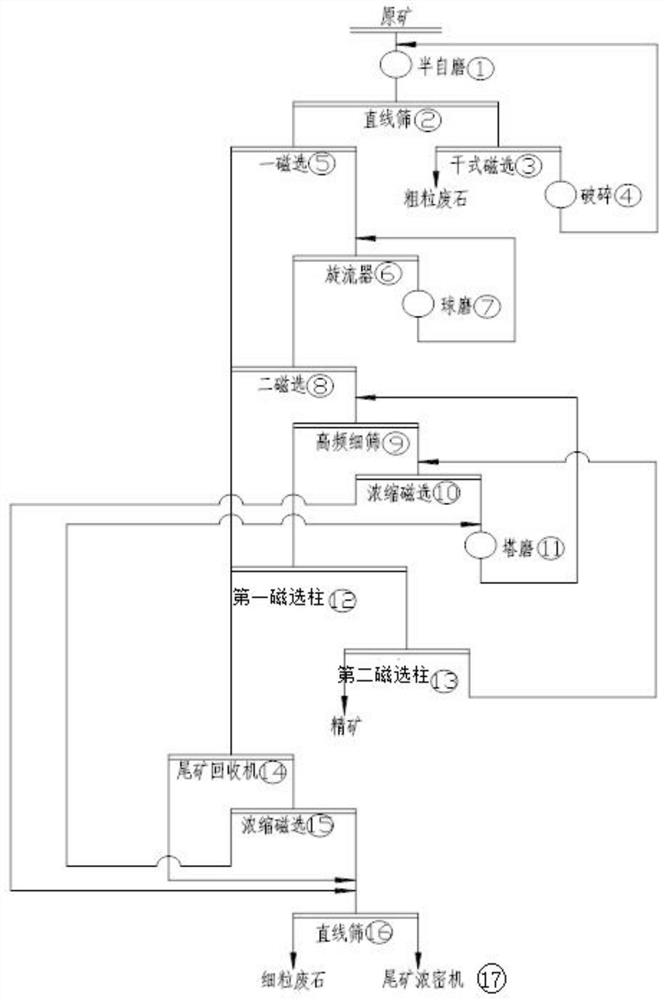

[0034] Such as figure 1 Shown, a kind of mineral processing method of magnetite, the step is:

[0035] A. The ore with a particle size of 0-350mm and a grade of 25%-35% is transported to a section of semi-autogenous mill 1 by the ore-collecting belt, and is self-ground to a particle size of -60mm;

[0036] B. The one-stage semi-autogenous mill discharges ore is screened by the linear sieve 2, and the products on the linear sieve 2 (-60mm—+3mm) are discarded by the weak magnetic dry separator 3, and the lump tailings are used as building materials, and the dry magnetic The concentrate enters the pebble crusher 4 for crushing, and the crushed products return to the semi-autogenous mill 1 for regrinding;

[0037] C, the product (-3mm) under the sieve of the linear sieve 2 enters a section of wet magnetic separator 5 for separation, the magnetic field strength is 350-400mT, and the grade of a section of magnetic concentrate is 45%-52%;

[0038] D. The first-stage magnetic concen...

Embodiment 2

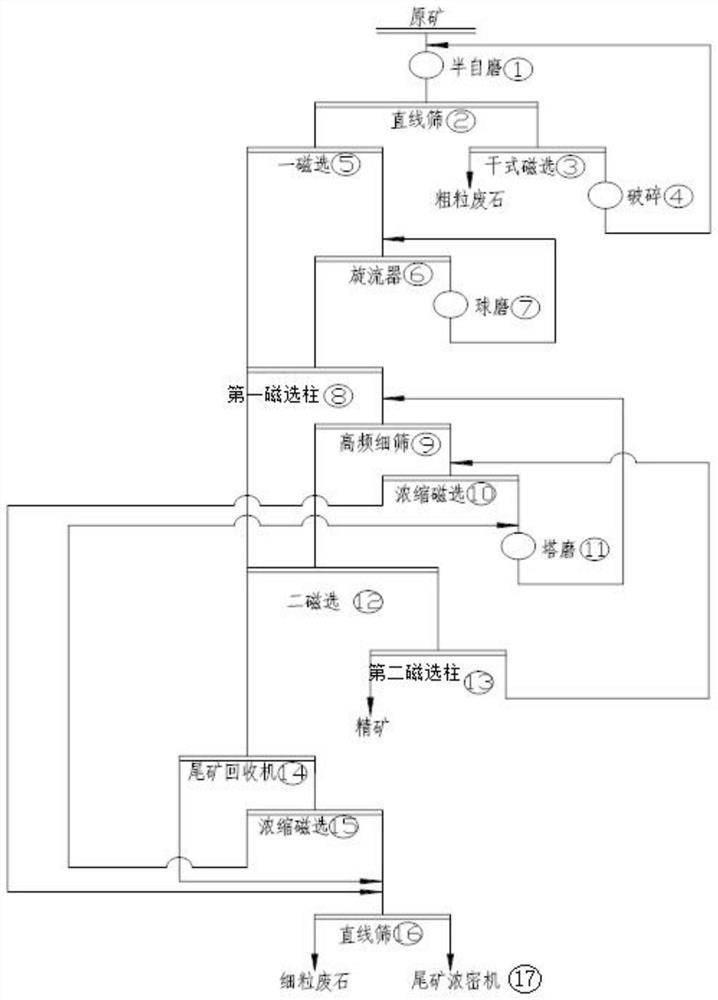

[0047] Such as figure 2 As shown, the second-stage weak magnetic separator in Scheme 1 is interchanged with the first magnetic separation column. In addition to providing the purpose of beneficiation, the first magnetic separation column also plays a role in desliming the concentrate. After the ore is deslimed in advance, the operating efficiency of the subsequent high-frequency fine screen 9 process can be improved, and the mud content of the concentrate can be reduced. After magnetic separation by the second-stage weak magnetic separator, the inclusion of the concentrate can be reduced and the grade of the concentrate can be improved.

[0048] A kind of ore dressing method of magnetite, the steps are:

[0049] A. The ore with a particle size of 0-350mm and a grade of 25%-35% is transported to a section of semi-autogenous mill 1 by the ore-collecting belt, and is self-ground to a particle size of -60mm;

[0050] B. The ore discharge (-60mm) of the first-stage semi-autogenou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com