Natural compound preservative for preserving beverages

A compound preservative and natural technology, applied in the direction of application, function of food ingredients, food ingredients as anti-microbial preservation, etc., can solve the problems of complex structure, low degree of automation, and small toxic and side effects of milling machines, and improve micro Circulation, good anti-corrosion effect, less toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A natural composite preservative for beverage storage, comprising 3-5 parts of purple salvia extract, 2-6 parts of ebony extract, and 1-4 parts of cassia bark extract in parts by weight, and depressurize after mixing uniformly Concentrate and dry to obtain a compound extract, which is rolled and pulverized to obtain the natural compound preservative;

[0042] This natural composite preservative for beverage storage is prepared by the following steps:

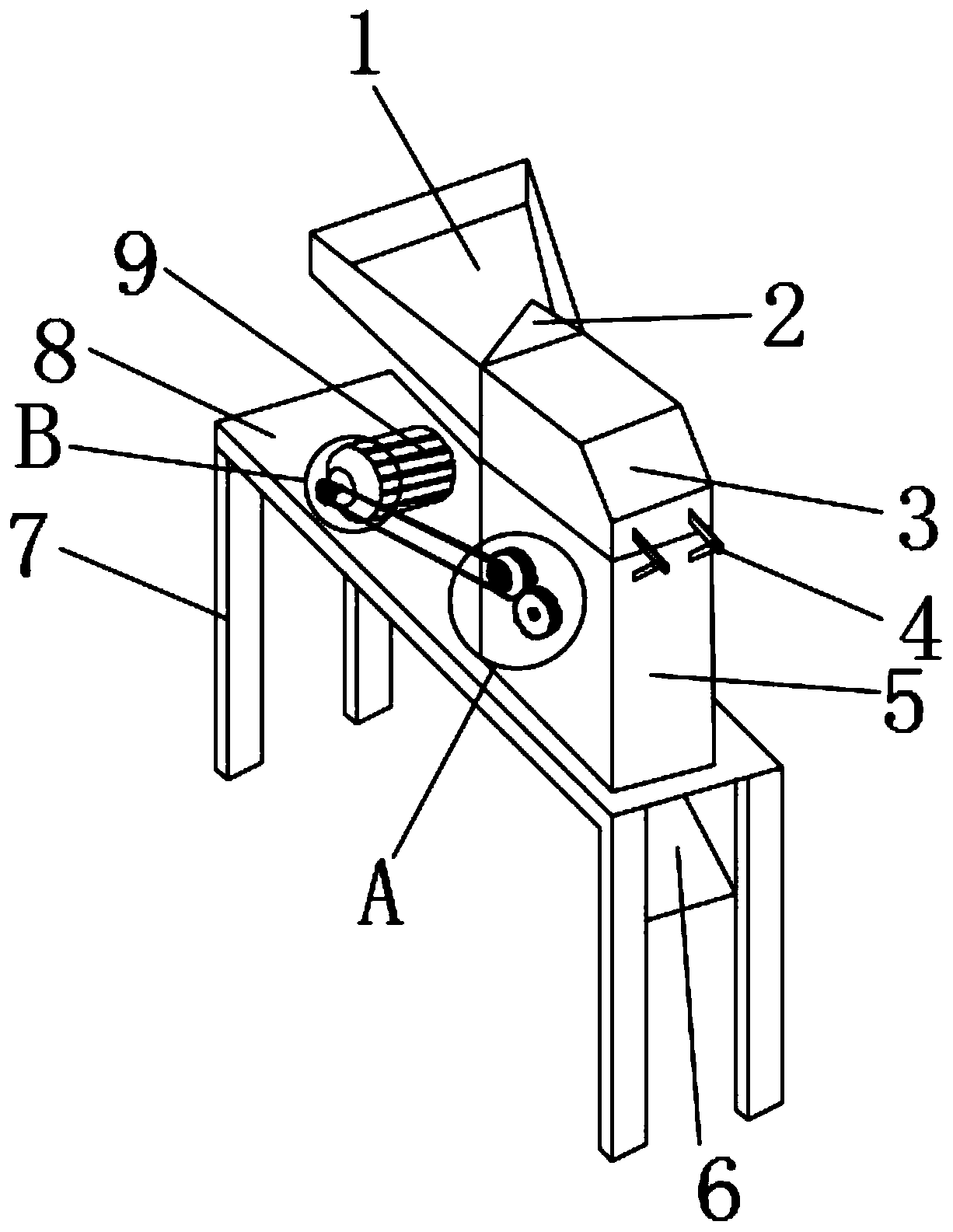

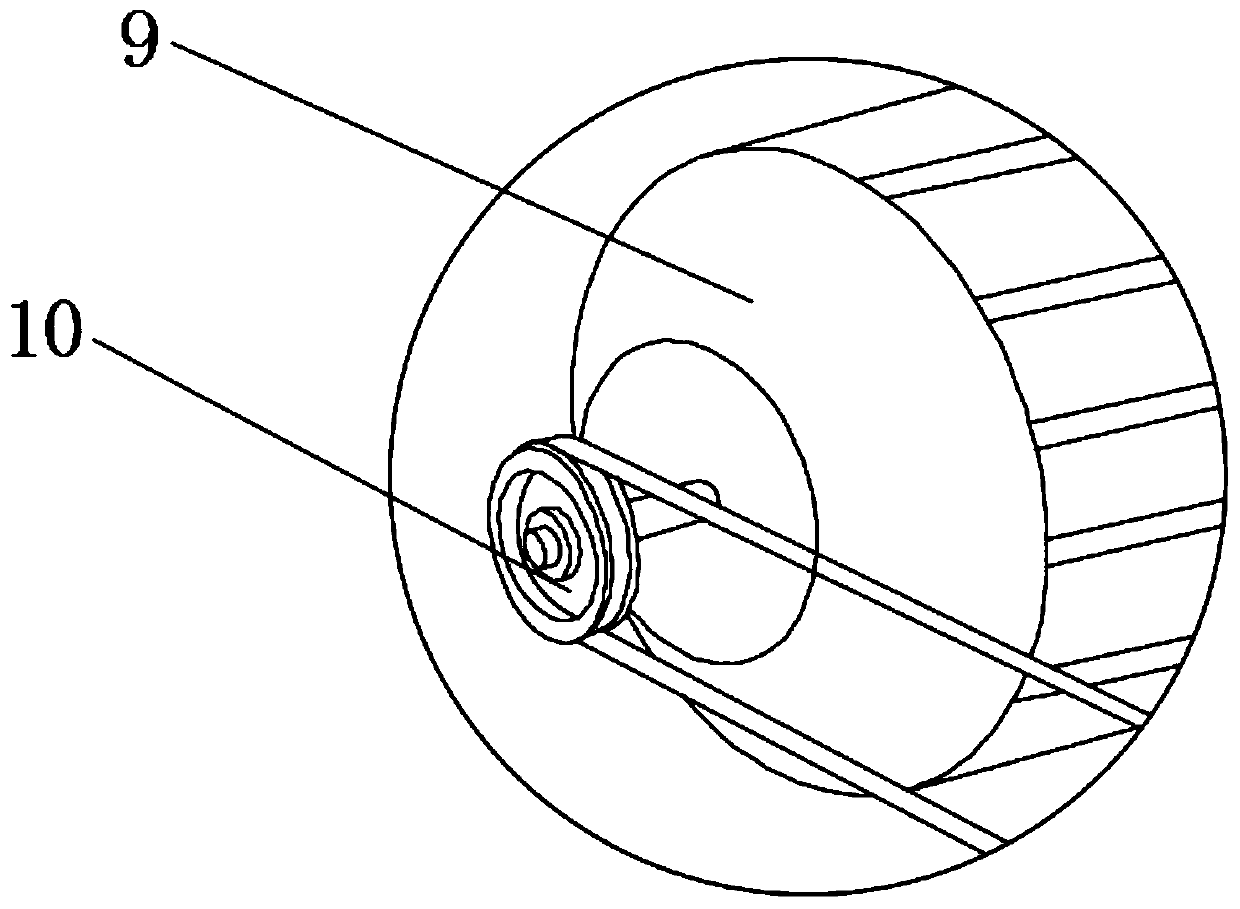

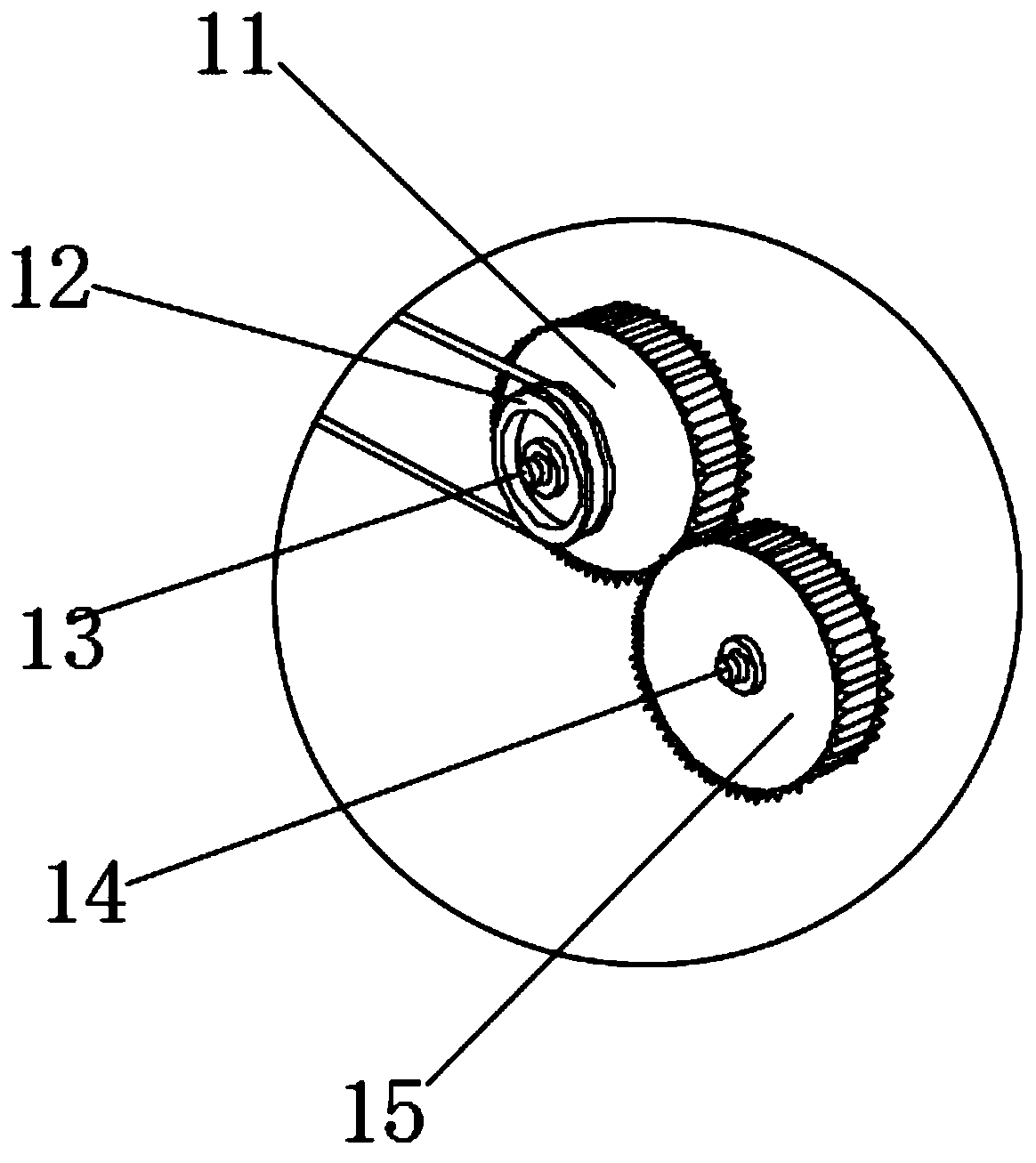

[0043] Step 1: Preparation of purple salvia miltiorrhiza extract: Weigh a certain amount of red salvia miltiorrhiza and dry to obtain dried red salvia miltiorrhiza, put the dried red salvia miltiorrhiza into the grinding device through the feeding hopper, and through diversion, the dried red salvia miltiorrhiza is dried At the occlusion of the first cutting knife and the second cutting knife, after cutting, the purple salvia miltiorrhiza particles are obtained, and the purple salvia miltiorrhiza particles fall between the...

Embodiment 2

[0054] see Figure 1-9 As shown, the present invention is a kind of natural compound antiseptic used for beverage storage, by weight, by 3-5 parts of purple salvia miltiorrhiza extract, 2-6 parts of ebony extract, 1-4 parts of cassia bark extract, through Concentrate under reduced pressure and dry after mixing evenly to obtain a compound extract, which is rolled and pulverized to obtain the natural compound preservative;

[0055] This natural composite preservative for beverage storage is prepared by the following steps:

[0056] Step 1: Preparation of purple salvia miltiorrhiza extract: Weigh a certain amount of red salvia miltiorrhiza and dry to obtain dried red salvia miltiorrhiza, put the dried red salvia miltiorrhiza into the grinding device through the feeding hopper, and through diversion, the dried red salvia miltiorrhiza is dried At the occlusion of the first cutting knife and the second cutting knife, after cutting, the purple salvia miltiorrhiza particles are obtai...

Embodiment 3

[0067] see Figure 1-9 As shown, the present invention is a kind of natural compound antiseptic used for beverage storage, by weight, by 3-5 parts of purple salvia miltiorrhiza extract, 2-6 parts of ebony extract, 1-4 parts of cassia bark extract, through Concentrate under reduced pressure and dry after mixing evenly to obtain a compound extract, which is rolled and pulverized to obtain the natural compound preservative;

[0068] This natural composite preservative for beverage storage is prepared by the following steps:

[0069] Step 1: Preparation of purple salvia miltiorrhiza extract: Weigh a certain amount of red salvia miltiorrhiza and dry to obtain dried red salvia miltiorrhiza, put the dried red salvia miltiorrhiza into the grinding device through the feeding hopper, and through diversion, the dried red salvia miltiorrhiza is dried At the occlusion of the first cutting knife and the second cutting knife, after cutting, the purple salvia miltiorrhiza particles are obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com