High-sensitivity large-strain flexible strain sensor and preparation method thereof

A strain sensor and high-sensitivity technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc., can solve the problems of no more than 2%, difficult balance, etc., and achieve the effects of improving conductivity, increasing effective volume, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Measure 90 mL of concentrated sulfuric acid and 30 mL of concentrated nitric acid solution, stir evenly in a 1000 mL beaker to obtain an acid solution; then weigh 0.2 g of multi-walled carbon nanotubes and slowly add them to the acidic mixed solution while stirring , and then stirred at 60 °C for 4 h after the reaction was completed; after the reaction, a large amount of deionized water was added to dilute the obtained solution, and the polyvinylidene fluoride membrane was used for suction filtration. The acidified multi-walled carbon nanotubes can be obtained by drying under vacuum for 48 h; the graphite oxide is prepared by the traditional Hummers method, and then the graphite oxide is placed in water and ultrasonically treated to obtain a monolithic dispersed graphene oxide dispersion. The vinylidene fluoride filter membrane was used for suction filtration. After all suction filtration was completed, the solid was collected and vacuum-dried at 80 °C for 48 h t...

Embodiment 2

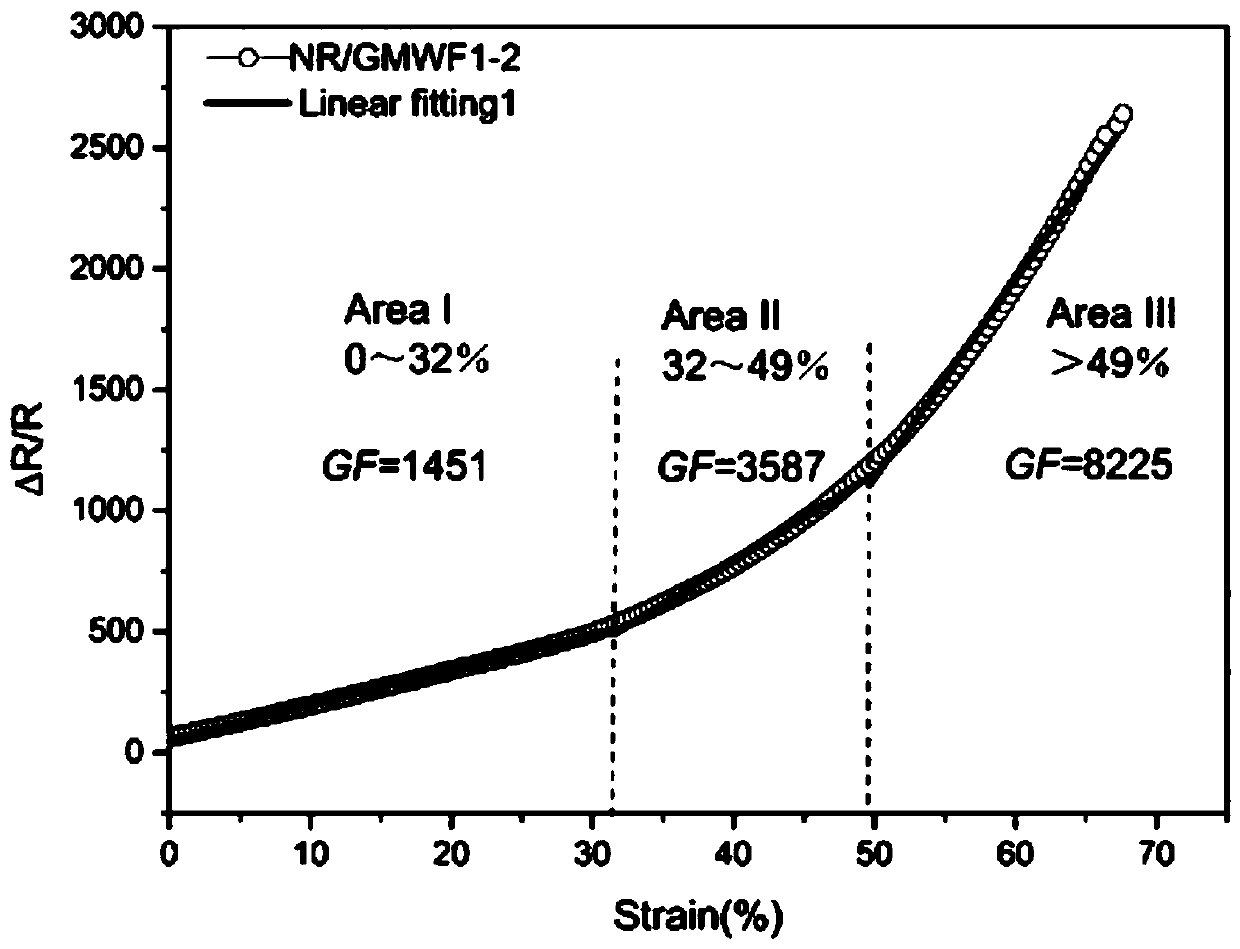

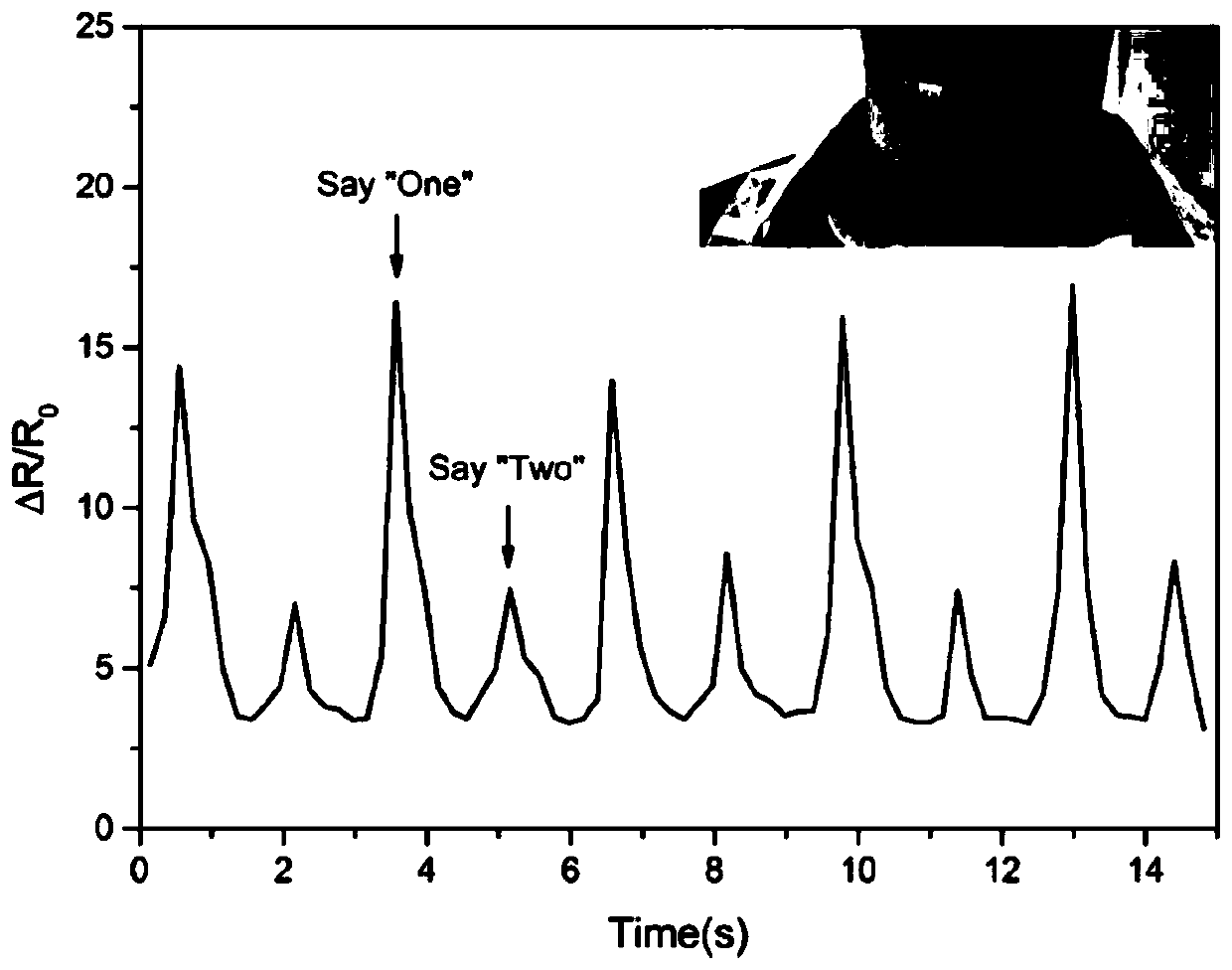

[0037] Repeat the method of Example 1 according to the specified components, but in step 1, the mass ratio of concentrated sulfuric acid and concentrated nitric acid is 2:1; in step 2, the ultrasonic power is 50 kHz, and the ultrasonic time is 2 h, and the obtained acidified The concentration of multi-walled carbon nanotubes / graphene oxide suspension was 2 mg / mL; in step 3, the immersion time was 1 h, and the thickness of the obtained multi-walled carbon nanotubes / graphene / carbonized absorbent cotton gauze three-dimensional hybrid network material was 2 nm; in step 4, the elastomer emulsion is styrene-butadiene rubber and natural rubber, the mass ratio is 1:1, the curing temperature is 60 °C, and the curing time is 5 h. The sensitivity index Gaugefactor (GF) of the obtained sensor is about 1375 (0 ε 0 ) / R 0 Δε, where R represents the resistance before deformation, R 0 Indicates the resistance after deformation, and Δε indicates the strain). When the strain is 7.5% and 50%, a...

Embodiment 3

[0039] Repeat the method of Example 1 according to the specified components, but in step 4, the elastomer emulsion is PDMS prepolymer and its curing agent diethylaminomethyltriethoxysilane. The sensitivity index Gaugefactor (GF) of the obtained sensor is about 1285 (0 ε 0 ) / R 0 Δε, where R represents the resistance before deformation, R 0 Indicates the resistance after deformation, and Δε indicates the strain). When the strain is 7.5% and 50%, after repeated 50 times, the sensitivity indexes are 1213 and 7819 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com