Carving device and method for front mixing type abrasive water jet directional cutting top plate

An abrasive water jet and roof technology, which is used in cutting machinery, discharge machinery, earth-moving drilling and mining, etc., can solve the problems of the adverse effect of the surrounding rock in the stope and the failure to use it, and achieves easy popularization, long acceleration time and high energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

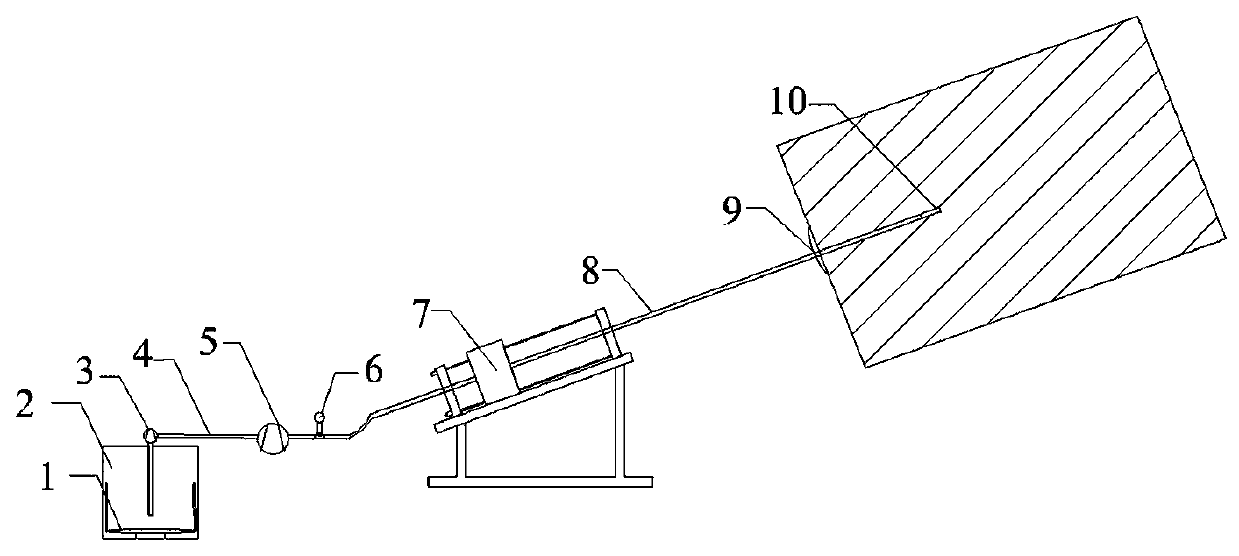

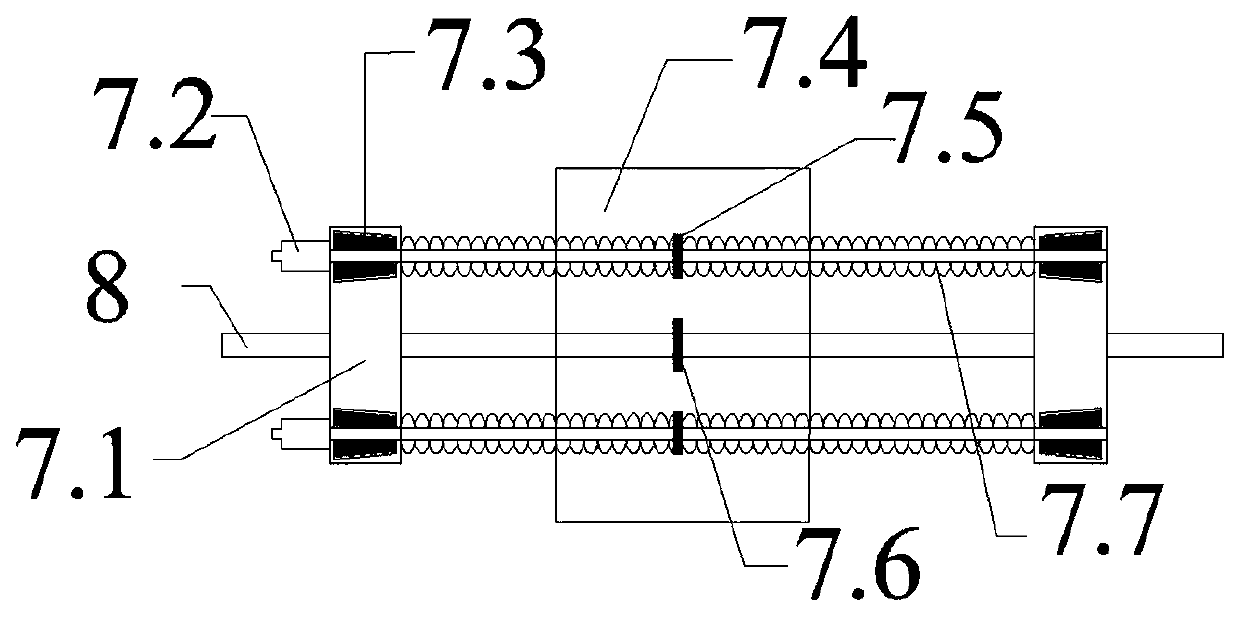

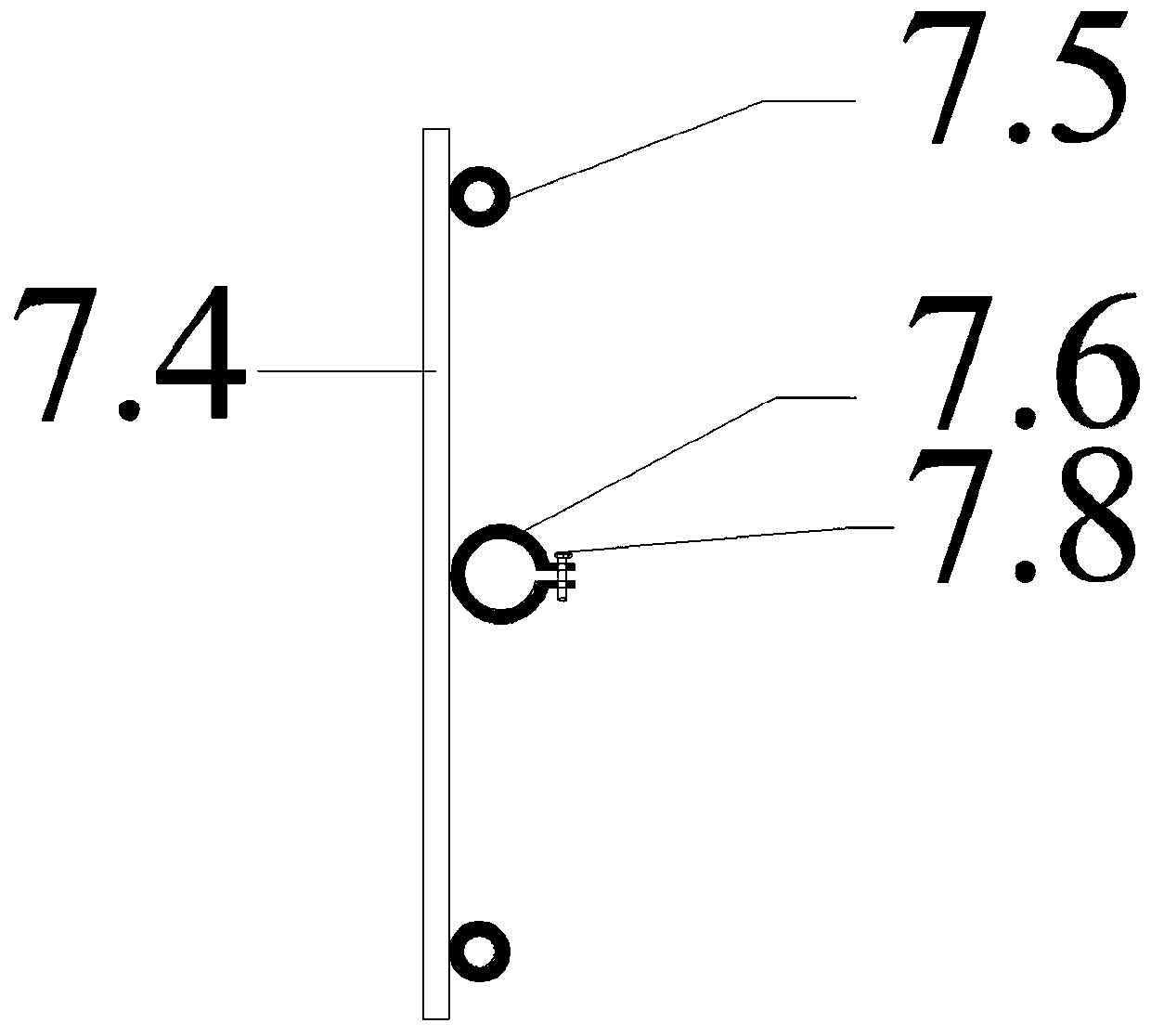

[0037] like figure 1 , shown in 2, 3, 4, 5, 6, 7, a top setting device for directional cutting of the top plate by a pre-mixed abrasive water jet, the device includes an anchor mixer 1, a water supply tank 2, a water pump 3, and a pipeline 4 , mud pump 5, pressure gauge 6, drill pipe transmission device 7, directional drill pipe 8, drill pipe direction control device 9, slotted bit 10, etc.; the drill pipe transmission device 7 includes two left and right parallel support piers 7.1 , each supporting pier 7.1 is provided with a horizontal through hole at the top and bottom, and two upper and lower parallel screw rods 7.7 are arranged between the two supporting piers 7.1. Both ends of the screw rod 7.7 pass through the supporting bearings installed in the through holes 7.3 It is rotatably connected with the support pier 7.1. The leftmost end of each lead screw 7.7 is driven to rotate by the motor 7.2. There is also a directional drill pipe installation hole in the middle of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com