Oxygen recovery control system and method for treating refractory nitrogen-containing concentrated organic wastewater by scwo

An organic waste water and control system technology, applied in electrical program control, comprehensive factory control, oxidized water/sewage treatment, etc., can solve problems such as oxygen recycling and utilization that have not been effectively solved, meet complex control requirements, ensure oxygen coefficient, improve The effect of the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

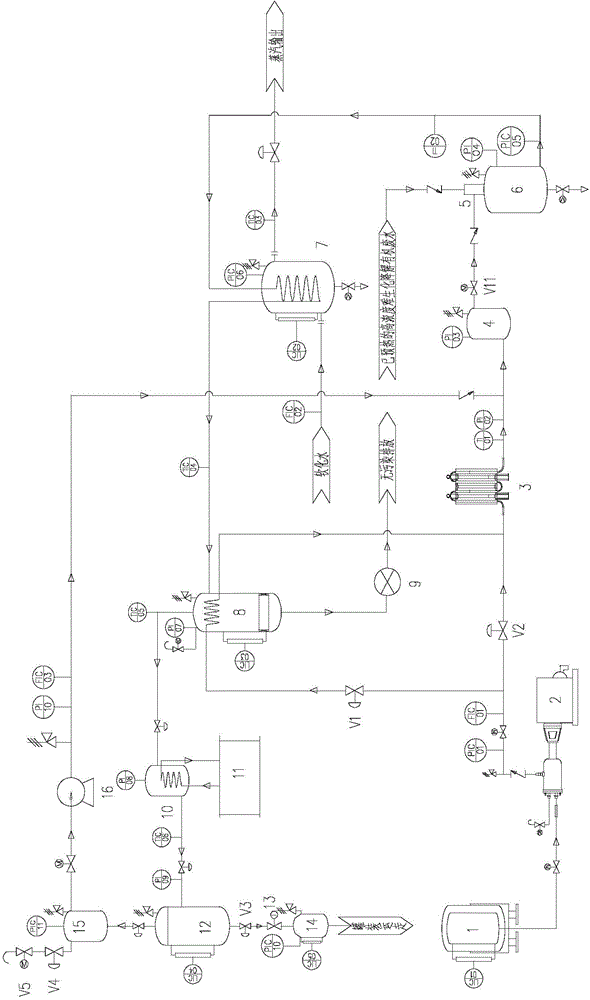

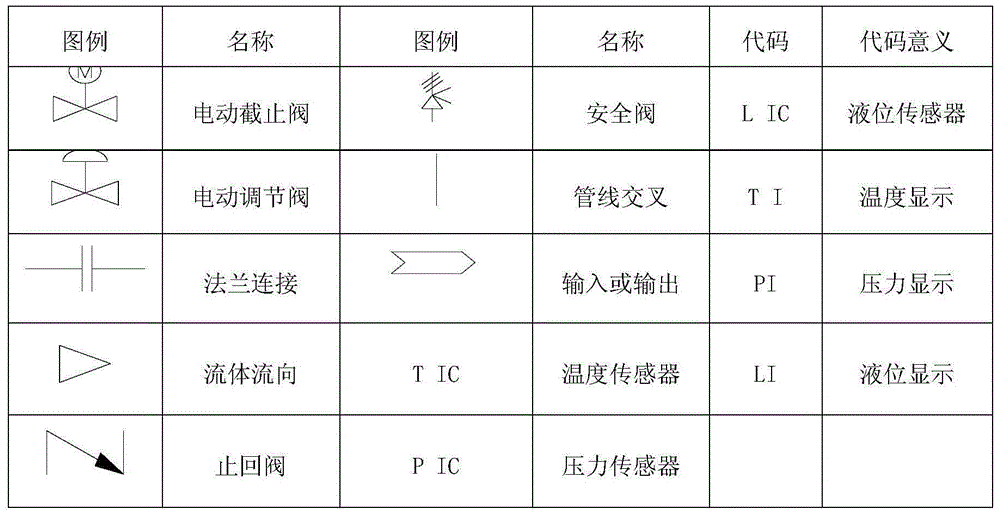

[0023] like figure 1 As shown, an oxygen recovery control system for supercritical water oxidation treatment of high-concentration and biodegradable nitrogen-containing organic wastewater: the outlet of liquid oxygen storage tank 1 is connected to the inlet of cryogenic liquid oxygen pump 2, and the outlet of cryogenic liquid oxygen pump 2 is connected to The inlet of the cooling coil in the vapor-liquid separator 8 is connected, the outlet of the cryogenic liquid oxygen pump 2 and the outlet of the cooling coil in the vapor-liquid separator 8 are simultaneously connected to the inlet of the liquid oxygen vaporizer 3, and the outlet of the liquid oxygen vaporizer 3 is connected to the The inlet port of the first buffer 4 is connected, the outlet port of the first buffer 4 is connected with the inlet port of the mixer 5, and the other inlet port of the mixer 5 is connected with a transport preheating pipeline for high-concentration, refractory biodegradable nitrogen-containing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com