A coking high-pressure ammonia water pressure control system and control method

A technology of pressure control and high-pressure ammonia water, applied in electrical program control, comprehensive factory control, coke oven, etc., can solve the problems of untimely switching of systems, single control mode, and inability to ensure long-term stability of high-pressure ammonia water pressure, etc., to ensure The effects of stable and continuous supply, improved control output, and long maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

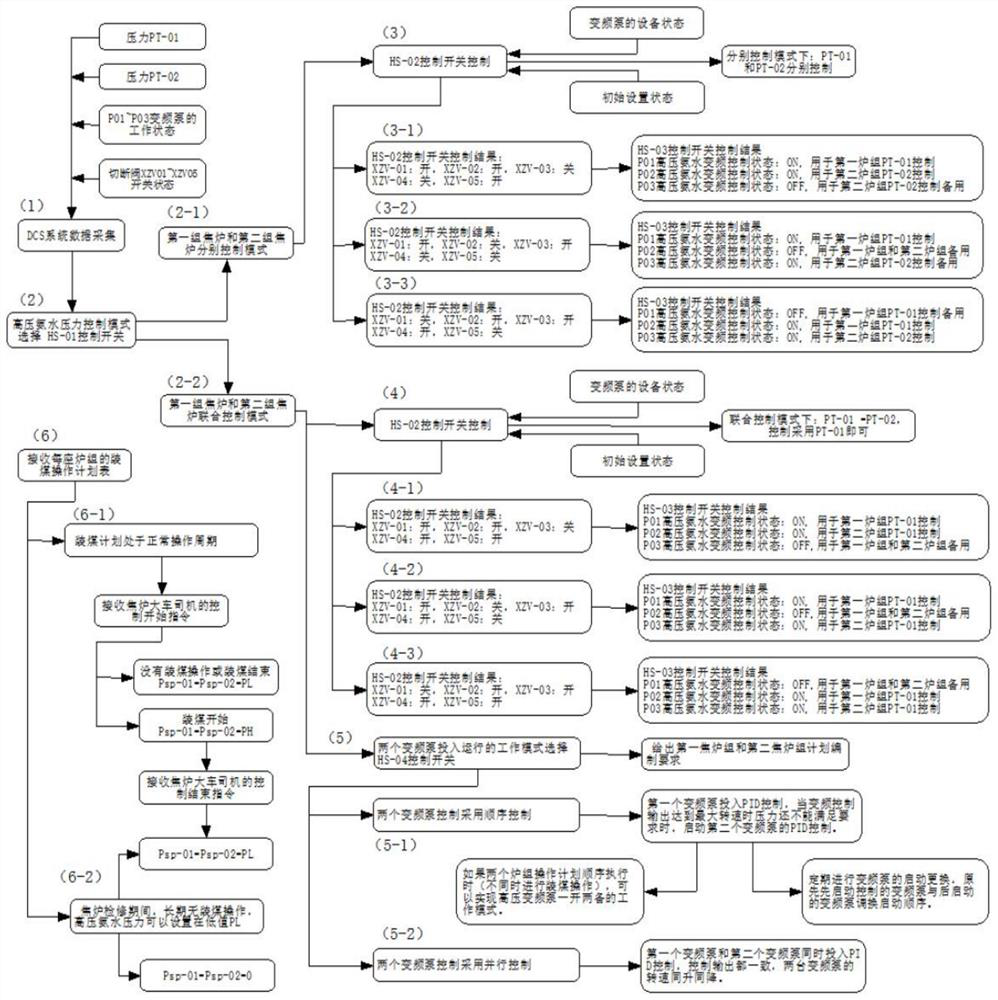

[0065] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

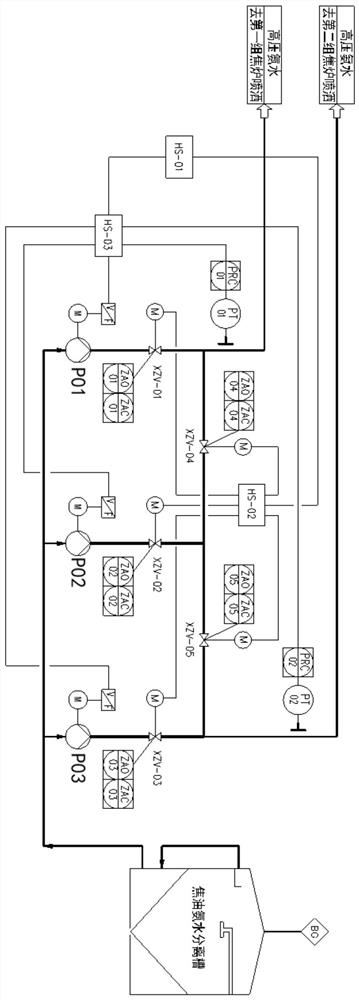

[0066] Such as figure 1 As shown, a coking high-pressure ammonia water pressure control system includes three high-pressure frequency conversion pumps: frequency conversion pump 1, frequency conversion pump 2 and frequency conversion pump 3; including five cut-off valves: cut-off valve 1, cut-off valve 2, cut-off valve 3, and cut-off valve Valve 4, cut-off valve 5; pressure transmitter 1 and pressure transmitter 2 are also included;

[0067] The inlets of frequency conversion pump 1, frequency conversion pump 2 and frequency conversion pump 3 are all set on the outlet pipeline of the tar ammonia water separation tank, and the outlet of frequency conversion pump 1 is provided with shut-off valve 1, and is connected to the ammonia spray pipe of the first group of coke ovens through shut-off valve 1 The outlet of frequency conversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com