Ultra-thick coating hot galvanized steel strip for underground pipe gallery corrugated pipe and production method thereof

A technology of underground pipe gallery and production method, which is applied in the direction of coating, hot-dip plating process, metal material coating process, etc., and can solve the problems of high core heat energy of thick steel strip, low air knife injection pressure, and slow production speed, etc. problems, to achieve the effect of suppressing zinc flow lines and edge thickness defects, increasing the air flow at the edge, and reducing the edge thickness of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

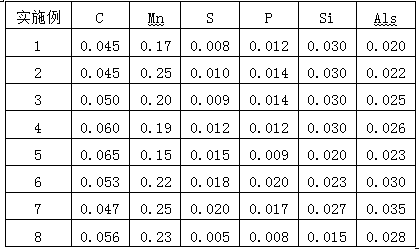

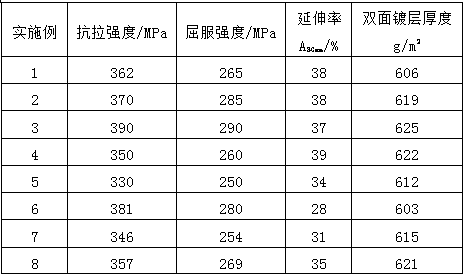

Embodiment 1

[0025] The specifications of the ultra-thick coated hot-dip galvanized steel strip for the bellows of the underground pipe gallery in this embodiment are: thickness 1.6mm, width 1396mm, and its chemical composition and mass percentage are shown in Table 1.

[0026] The production method of the ultra-thick coated hot-dip galvanized steel strip for the corrugated pipe of the underground pipe gallery in this embodiment includes converter smelting, LF refining, continuous casting, hot rolling, cold rolling and galvanizing processes, and the specific process steps are as follows:

[0027] (1) LF refining process: After smelting, the molten steel enters LF refining, and the refined molten steel C: 0.045%, Mn: 0.17%;

[0028] (2) Hot rolling process: the heating temperature is 1230°C, the final rolling temperature is 892°C, and the crimping temperature is 660°C;

[0029] (3) Cold rolling process: the hot-rolled strip is cold-rolled after pickling, the total reduction rate of cold-rol...

Embodiment 2

[0033] The specifications of the ultra-thick coated hot-dip galvanized steel strip for the bellows of the underground pipe gallery in this embodiment are: thickness 1.6mm, width 1396mm, and its chemical composition and mass percentage are shown in Table 1.

[0034] The production method of the ultra-thick coated hot-dip galvanized steel strip for the corrugated pipe of the underground pipe gallery in this embodiment includes converter smelting, LF refining, continuous casting, hot rolling, cold rolling and galvanizing processes, and the specific process steps are as follows:

[0035] (1) LF refining process: After smelting, molten steel enters LF refining, and the refined molten steel C: 0.045%, Mn: 0.25%;

[0036] (2) Hot rolling process: the heating temperature is 1235°C, the final rolling temperature is 890°C, and the crimping temperature is 662°C;

[0037] (3) Cold rolling process: the hot-rolled strip is cold-rolled after pickling, the total reduction rate of cold-rolling...

Embodiment 3

[0041] The specifications of the ultra-thick coated hot-dip galvanized steel strip for the bellows of the underground pipe gallery in this embodiment are: thickness 1.3mm, width 1250mm, and its chemical composition and mass percentage are shown in Table 1.

[0042] The production method of the ultra-thick coated hot-dip galvanized steel strip for the corrugated pipe of the underground pipe gallery in this embodiment includes converter smelting, LF refining, continuous casting, hot rolling, cold rolling and galvanizing processes, and the specific process steps are as follows:

[0043](1) LF refining process: After smelting, the molten steel enters LF refining, and the refined molten steel C: 0.050%, Mn: 0.20%;

[0044] (2) Hot rolling process: the heating temperature is 1240°C, the final rolling temperature is 895°C, and the crimping temperature is 656°C;

[0045] (3) Cold rolling process: the hot-rolled strip is cold-rolled after pickling, the total reduction rate of cold-roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com