A p-phenylenediamine dissolving system and method for continuous polymerization of aramid fiber 1414

A technology of p-phenylenediamine and aramid fiber, which is applied in the field of man-made fiber production equipment, can solve the problems of long dissolution time of p-phenylenediamine, high temperature of organic solvent, easy oxidation of p-phenylenediamine, etc., and achieve simple structure, Improves stability and prevents moisture contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

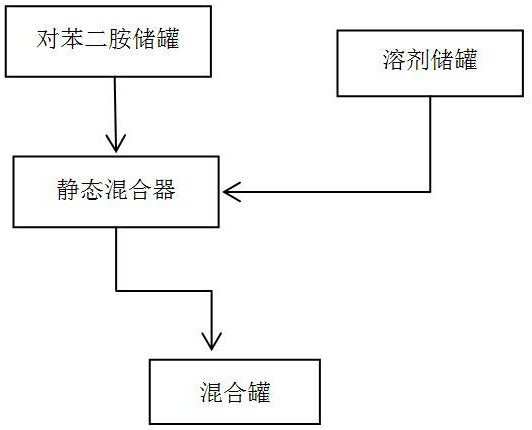

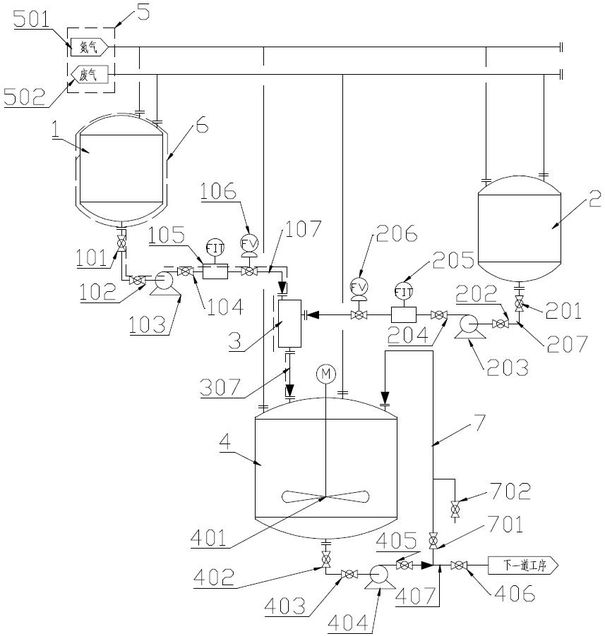

[0062] Such as figure 2 Shown: a p-phenylenediamine dissolving system for the continuous polymerization of aramid fiber 1414, including a p-phenylenediamine storage tank 1 for storing p-phenylenediamine in a molten state after rectification, and a storage tank for storing organic solvents Solvent storage tank 2, static mixer 3 for pre-mixing p-phenylenediamine and organic solvent, mixing tank 4 for remixing p-phenylenediamine and organic solvent, insulation device 6 for insulating p-phenylenediamine and Nitrogen blanketing device 5 for sealing to prevent oxygen and moisture from contacting p-phenylenediamine,

[0063] The p-phenylenediamine storage tank 1 is connected with the static mixer 3 through the p-phenylenediamine delivery pipe 107, the solvent storage tank 2 is connected with the static mixer 3 through the solvent delivery pipe 207, and the static mixer 3 is mixed with the mixing delivery pipe 307. tank 4 connection;

[0064] The heat preservation device 6 is conne...

Embodiment 2

[0067] On the basis of embodiment 1, further,

[0068] The nitrogen sealing device 5 includes a nitrogen tank 501 and a waste gas tank 502, the nitrogen tank 501 and the waste gas tank 502 are connected to the p-phenylenediamine storage tank 1, and the nitrogen tank 501, the waste gas tank 502 and the p-phenylenediamine storage tank 1 are three A nitrogen passage for p-phenylenediamine nitrogen blanketing is formed between them;

[0069] Both the nitrogen tank 501 and the waste gas tank 502 are connected to the solvent storage tank 2, and the nitrogen tank 501, the waste gas tank 502 and the solvent storage tank 2 form a nitrogen passage for the nitrogen seal of the organic solvent, thereby preventing the organic solvent from bringing in oxygen and moisture After entering the static mixer 3, p-phenylenediamine is affected, that is, indirect p-phenylenediamine is sealed;

[0070] Both the nitrogen tank 501 and the waste gas tank 502 are connected to the mixing tank 4, and a ni...

Embodiment 3

[0072] On the basis of embodiment 1-2, further,

[0073]The nitrogen inlet on the p-phenylenediamine storage tank 1 is connected to the heat preservation device 6, and the exhaust gas outlet on the p-phenylenediamine storage tank 1 is connected to the heat preservation device 6, which effectively prevents the nitrogen inlet and the waste gas outlet from being volatilized by the molten p-phenylenediamine. Solidified crystals clog the delivery tube.

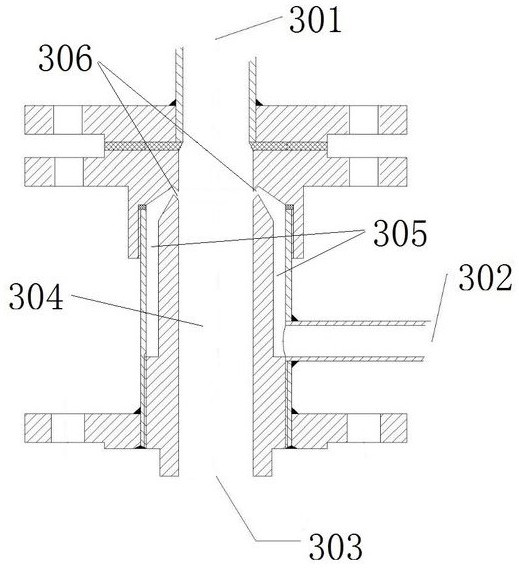

[0074] Such as image 3 As shown: the upper part of the static mixer 3 is provided with a p-phenylenediamine inlet 301, the middle part is provided with a solvent inlet 302, the lower part is provided with a premix outlet 303, and the inside is provided with a mixing chamber 304 for premixing; p-phenylenediamine inlet 301 It is arranged above the mixing chamber 304, and the premix outlet 303 is arranged below the mixing chamber 304, and the premix outlet 303 is connected to the mixing delivery pipe 307; the static mixer 3 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com