Preparation method and application of tung oil-based polymer and preparation method of tung oil-based polymer derivative

A polymer and derivative technology, applied in the preparation of tung oil-based polymer derivatives and the field of tung oil-based polymer preparation, can solve the problems of increased volatile organic compounds, chlorinated hydrocarbons harmful to human body, low boiling point, etc., and achieve plasticization The effect of high efficiency, cheap price and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 Preparation of tung oil-based polymer

[0046] It includes the following steps:

[0047] S1, add methyl eleostearate and olive oil into the reaction vessel, then feed nitrogen into the reaction vessel, then add 10% of the weight of methyl eleostearate to boron trifluoride ether, heat up to 60°C, and stir for 0.5h Wherein, the weight ratio of methyl eleostearate and olive oil is 1:1;

[0048] S2, after the reaction finishes, add a sufficient amount of the first solvent dichloromethane, and after the reaction product is fully dissolved, add the second solvent acetone, so that the tung oil-based polymer is separated out, centrifuged, and the precipitate is taken to obtain the tung oil-based polymer; wherein, the first The volume ratio of the solvent and the second solvent was 1:5.

[0049] The yield of the polymer was 75% (about 20% of the methyl eleostearate was non-conjugated fatty acid ester) and the purity was 95%.

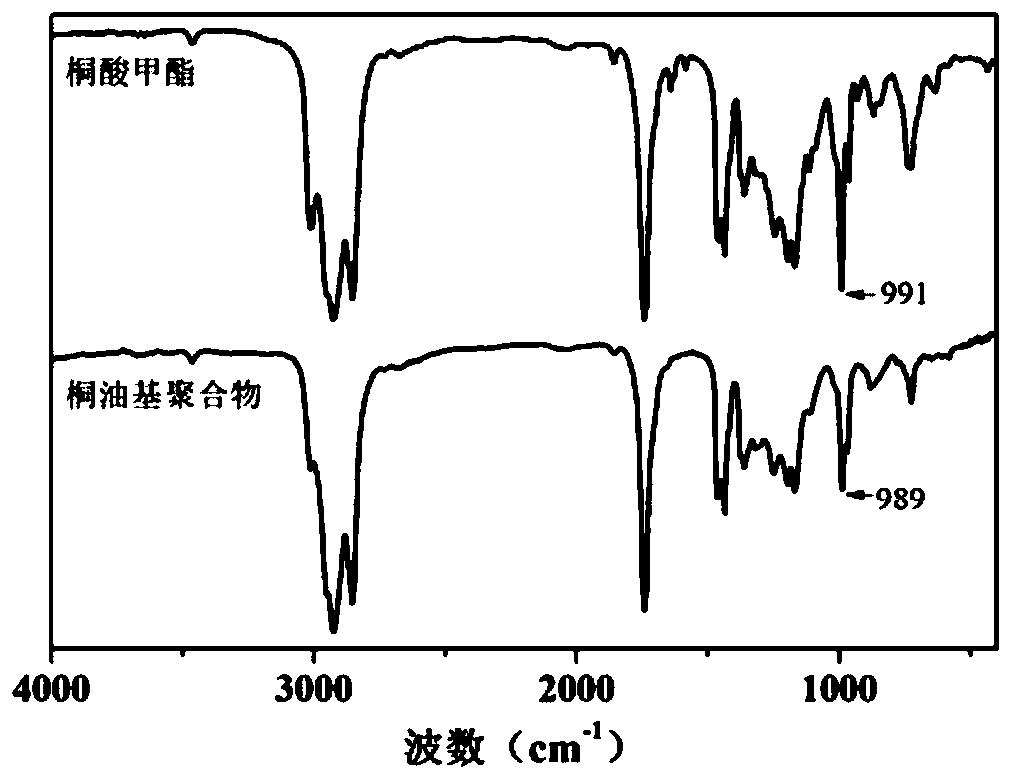

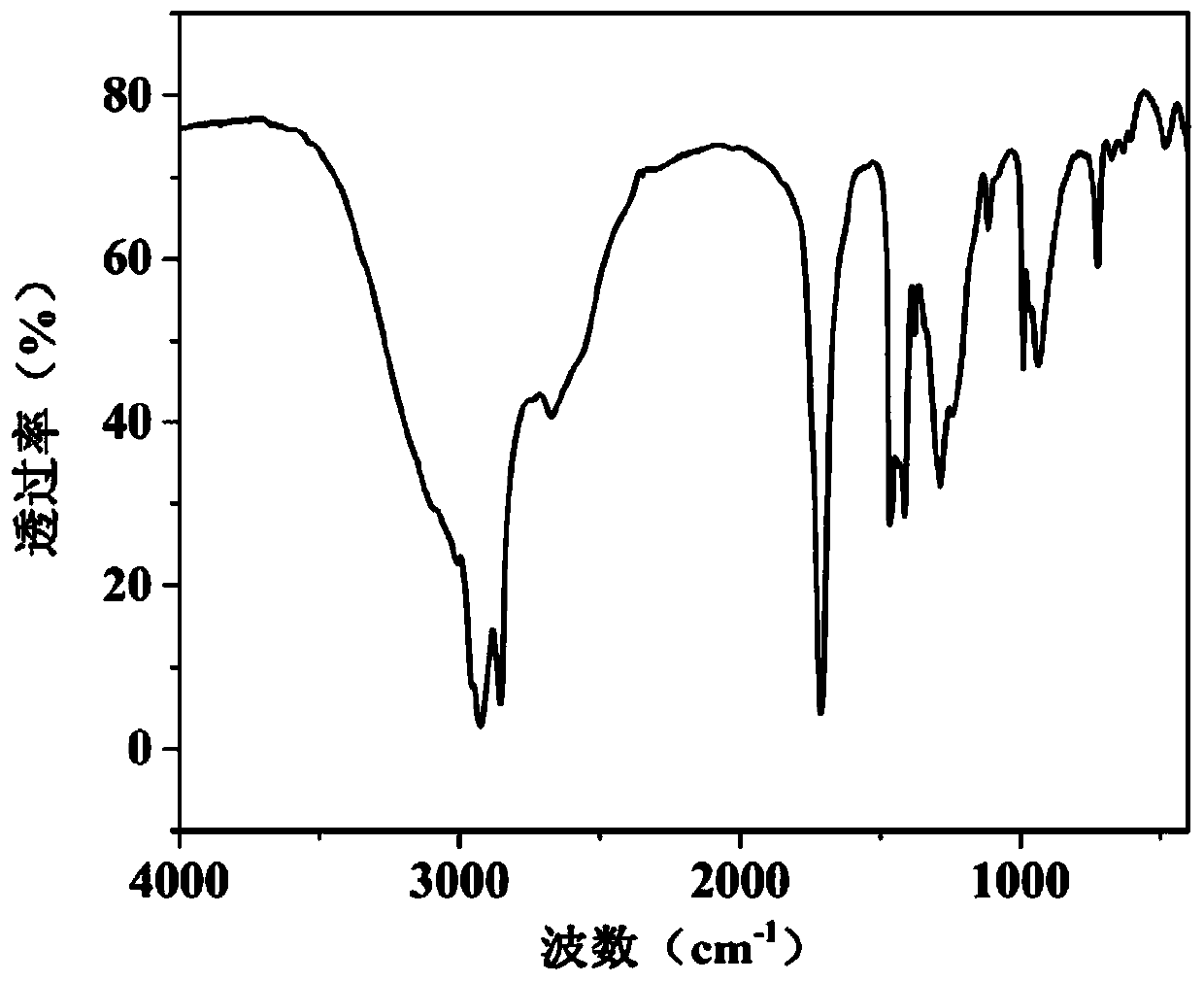

[0050] The tung oil-based polymer was c...

Embodiment 2

[0052] Example 2 Preparation of tung oil-based polymer

[0053] It includes the following steps:

[0054] S1, add methyl eleostearate and palm oil into the reaction vessel, then feed nitrogen into the reaction vessel, then add 1% aluminum trichloride by weight of methyl eleostearate, heat up to 30°C, and stir for 10h; wherein , the weight ratio of palm oil and methyl eleostearate is 5:1;

[0055] S2. After the reaction, add ethyl acetate and ethanol in turn, the volume ratio of ethyl acetate and ethanol is 1:8, and centrifuge the precipitate to obtain a tung oil-based polymer. The yield of the polymer is 77% and the purity is 94%. .

[0056] The FTIR spectrum of the tung oil-based polymer was obtained by testing with the Nicolet iS10 Fourier transform infrared spectrometer of Thermo Fisher Scientific, and the characteristic peaks of the obtained result were the same as those in Example 1.

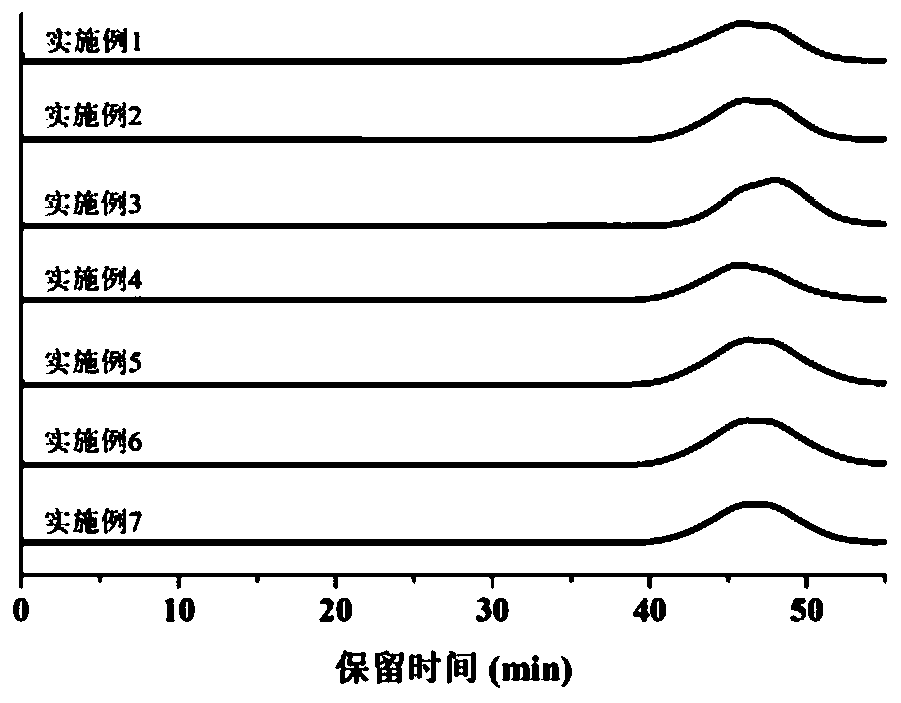

[0057] The GPC diagram of the tung oil-based polymer obtained by the Waters gel perm...

Embodiment 3

[0058] Example 3 Preparation of tung oil-based polymer

[0059] It includes the following steps:

[0060] S1, add methyl eleostearate and coconut oil into the reaction vessel, then feed nitrogen into the reaction vessel, then add 10% titanium tetrachloride by weight of methyl eleostearate, be warming up to 50 ° C, and stir for 8h; wherein , the weight ratio of coconut oil and methyl eleostearate is 5:1;

[0061] S2. After the reaction, tetrahydrofuran and acetic acid were added successively, and the volume ratio of tetrahydrofuran and acetic acid was 1:6, and the precipitate was centrifuged to obtain a tung oil-based polymer. The yield of the polymer was 76% and the purity was 96%.

[0062] The FTIR spectrum of the tung oil-based polymer was obtained by testing with the Nicolet iS10 Fourier transform infrared spectrometer of Thermo Fisher Scientific, and the characteristic peaks of the obtained result were the same as those in Example 1.

[0063] The GPC diagram of the tung ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap