Foamed rubber cloth cutting and winding integrated treatment equipment

A comprehensive processing and foaming rubber technology, applied in the direction of thin material processing, winding strips, sending objects, etc., can solve the problems that the quality of cutting cannot meet the requirements, there is no corresponding cutting, and the roll-up is loose. To achieve the effect of ensuring the safety of operation, simple structure and tight rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

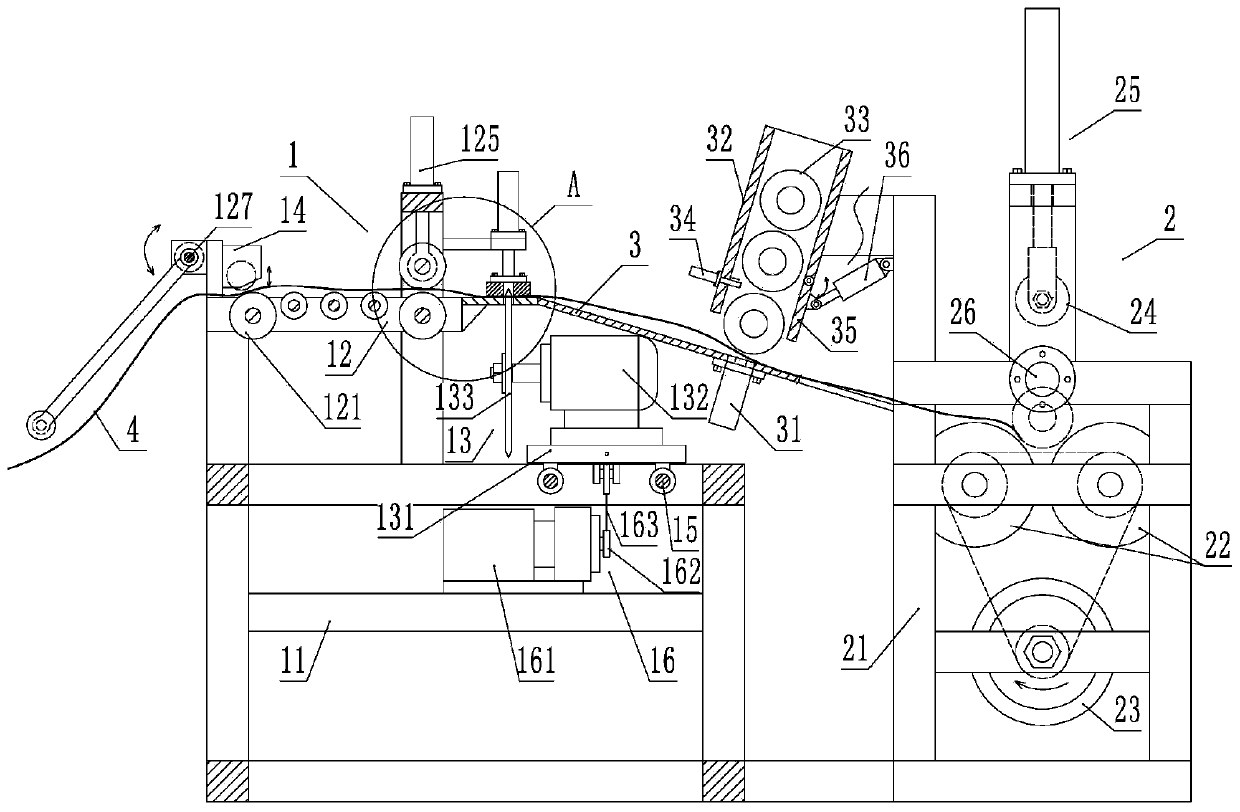

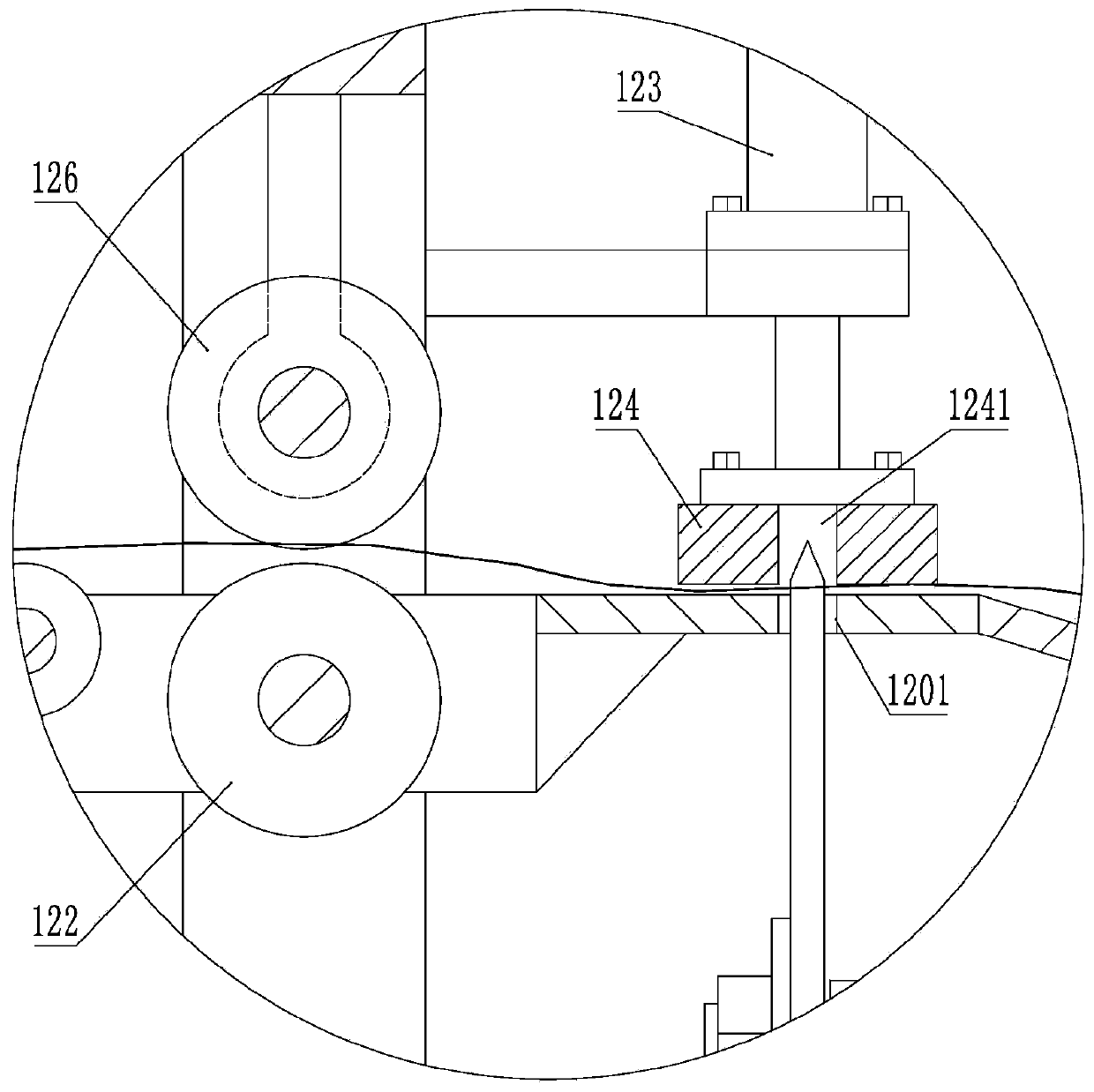

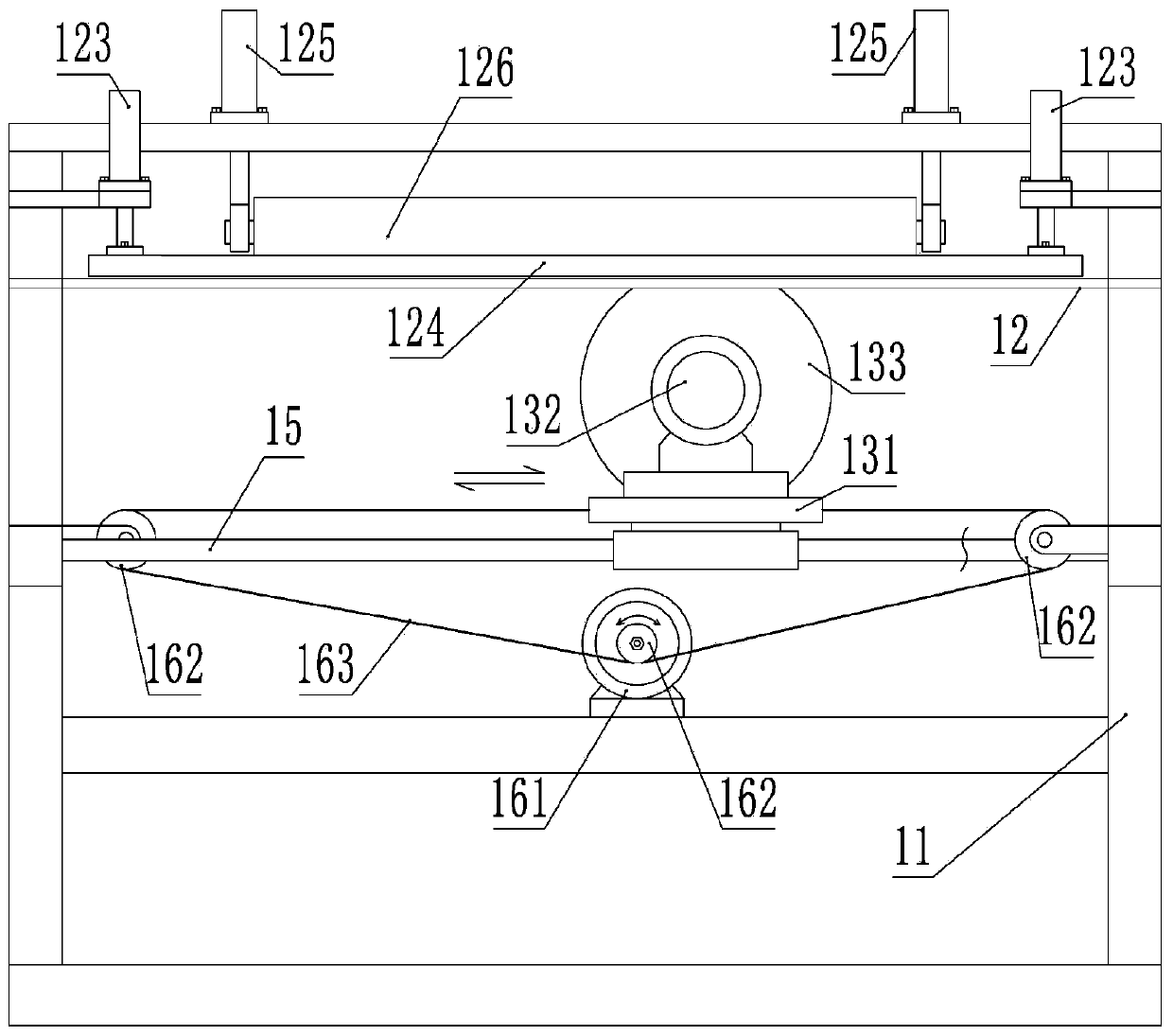

[0032] Such as Figure 1-8As shown, the specific structure of the present invention is: a comprehensive treatment equipment for cutting and rolling foamed rubber cloth, including a cutting device 1 and a retracting device 2, the discharge end of the cutting device 1 and the feeding end of the retracting device 2 A material guide plate 3 is inclined between the ends, and the side of the material guide plate 3 near the retracting device 2 is lower; the cutting device 1 includes a cutting frame 11, a cutting workbench 12, a transverse cutting mechanism 13 and an Cutting mechanism 14, the cutting workbenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com