Plated piston rod assembly polishing processing device and processing method thereof

A technology for processing equipment and piston rods, applied in metal processing equipment, grinding/polishing equipment, control of workpiece feed movement, etc., can solve problems such as low processing efficiency, long average workpiece time, long polishing and inspection time, etc. Achieve the effects of high processing efficiency, accelerated processing rhythm, and short walking stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The invention provides a polishing processing equipment and processing method of a piston rod assembly after plating, which polishes the surface of the piston rod assembly after chrome plating and detects the polishing effect.

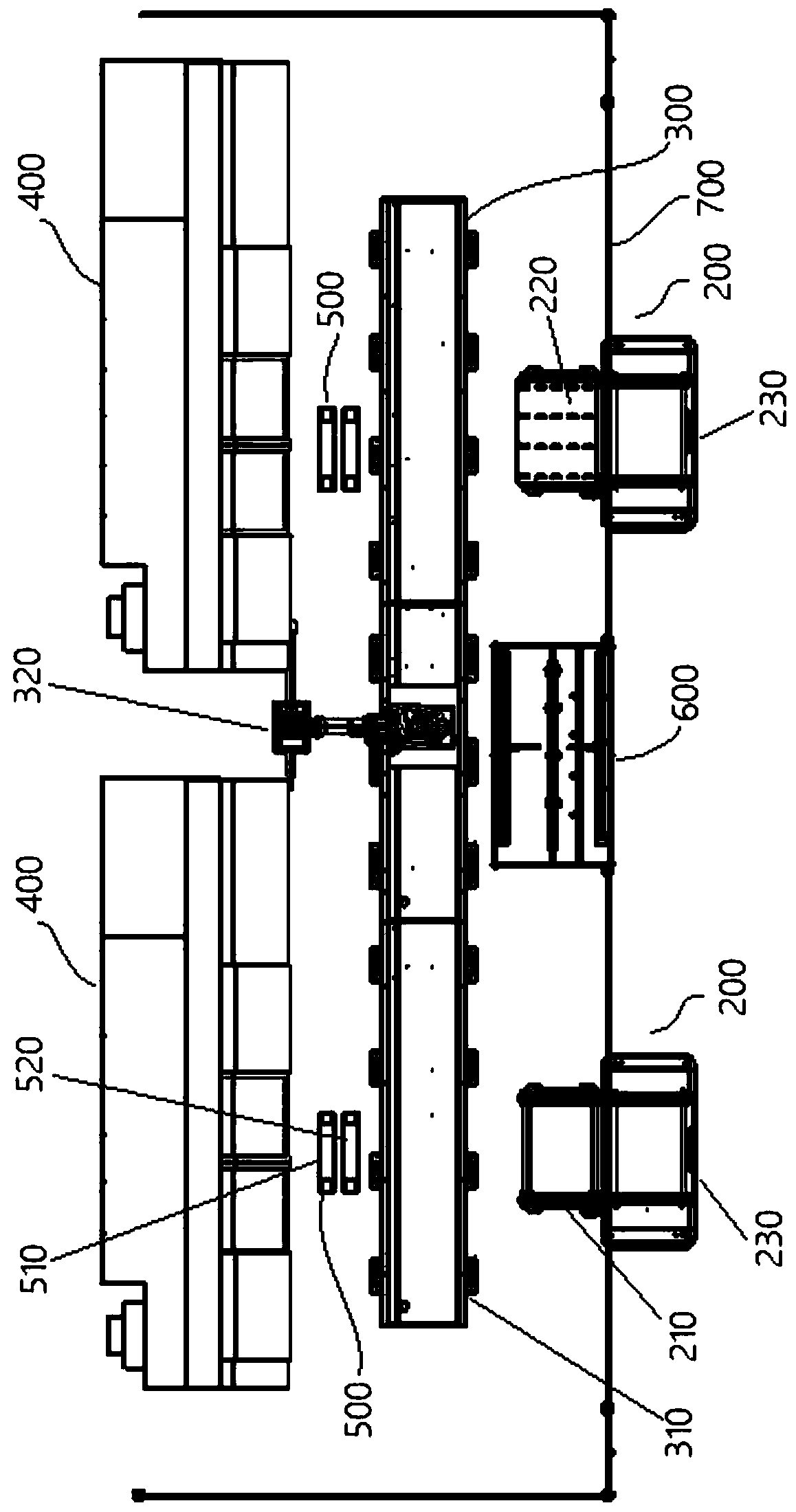

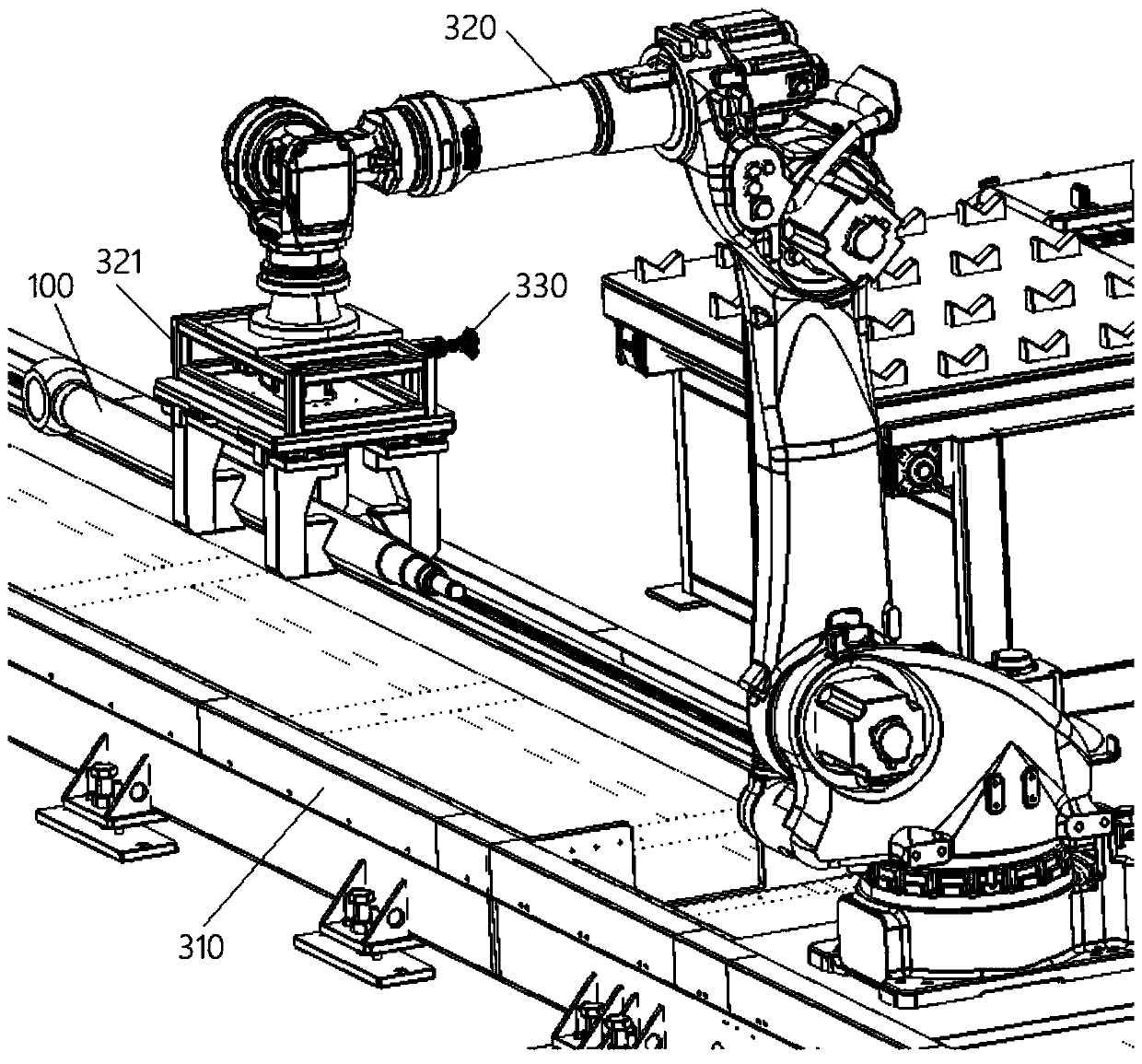

[0060] Such as figure 1 As shown, the equipment includes a loading and unloading buffer station 200 , a ground rail robot 300 , an outer cylindrical grinder 400 , a grinding machine buffer station 500 and a detection platform 600 .

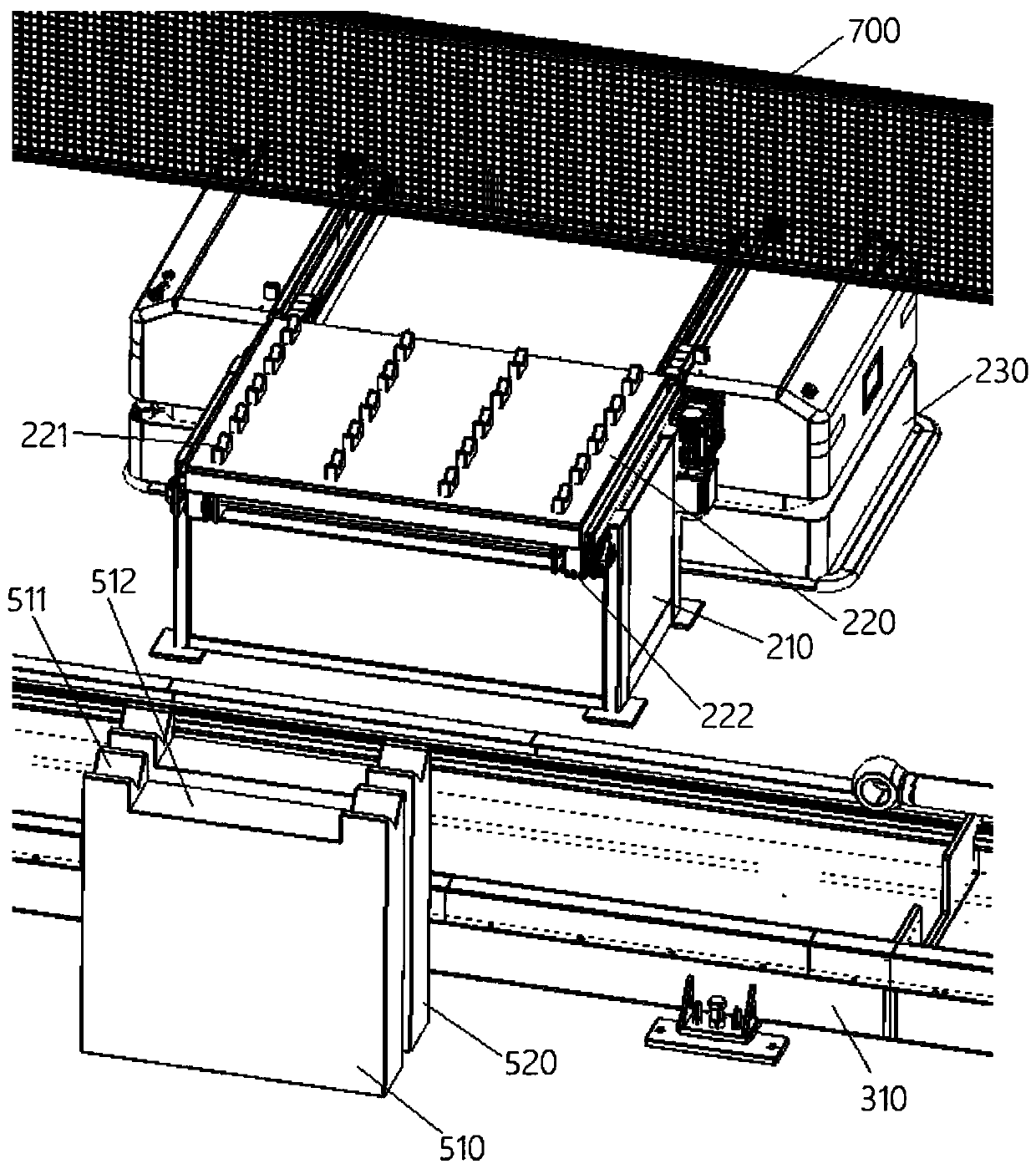

[0061] Such as figure 1 with figure 2 As shown, two loading and unloading buffer stations 200 are distributed on the front side of the ground rail robot 300 at intervals along the left and right directions. The loading and unloading cache station 200 includes a tray cache table 210 and a workpiece tray 220. The tray cache table 210 is fixed on the ground, and the workpiece tray 220 can be placed on the tray cache table 210; the workpiece tray 220 is used to store the workpiece to be polished. The piston rod asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com