A chest lock integrated part and its preparation method

A one-piece, sternlock technology, applied in prostheses, medical science, bone implants, etc., can solve problems such as poor mechanical properties, autologous osteocompatibility, loosening or dislocation of implants, and delayed bone healing, etc., to improve biological Compatibility, improve binding ability, reduce the effect of shedding and transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

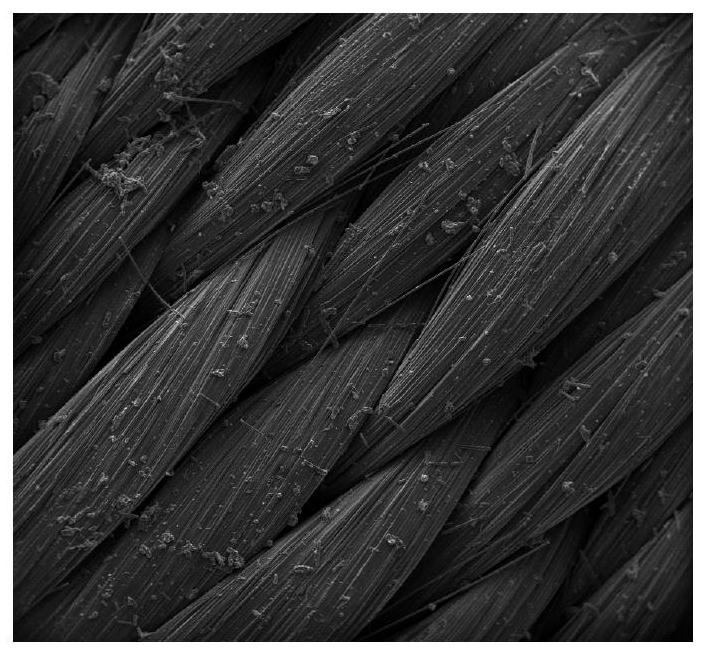

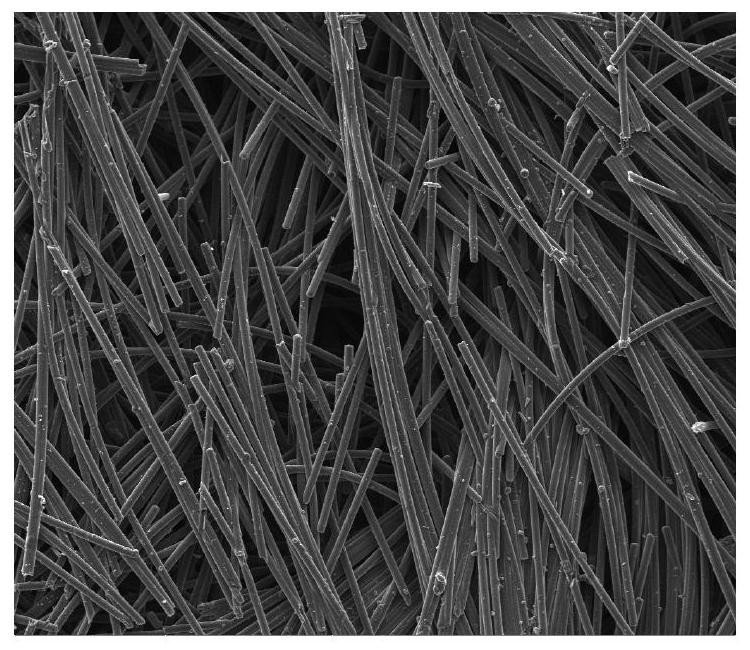

[0044] 1) Twisting two bundles of 6k carbon fibers into a carbon fiber rope with a twist of 200 twists / m; then weaving 24 twisted carbon fiber ropes into a strip-shaped continuous carbon fiber braid. The area density is 30g / m2 by needle needle 2 The carbon fiber nonwoven fabric is riveted on the continuous carbon fiber braid, and the riveting point density is 10 points / cm 2 , to obtain the prefabricated body of carbon fiber sternum slice. Weave 2 bundles of 6k carbon fiber twisted ropes with a twist of 200 twists / m, and 10 twisted carbon fiber ropes into a strip to obtain a prefabricated carbon fiber clavicle strip. Two bundles of 6k carbon fiber twisted ropes with a twist of 200 twists / m are braided into strips, and then spirally wound into a spring through a rod-shaped carbon material mold with one coil to obtain a carbon fiber joint prefabricated body. Extend the carbon fiber at both ends of the joint prefabricated body into the carbon fiber at the connecting end of the c...

Embodiment 2

[0053] 1) Twisting 3 bundles of 12k carbon fibers into a carbon fiber rope with a twist of 300 twists / m; then weaving 12 twisted carbon fiber ropes into a strip-shaped continuous carbon fiber braid. The area density is 20g / m2 by needle needle 2 The carbon fiber non-woven fabric is riveted on both surfaces of the continuous carbon fiber braid to form a sandwich structure, and the riveting point density is 10 points / cm 2 , to obtain the prefabricated body of carbon fiber sternum slice. Three bundles of 12k carbon fiber twisted ropes with a twist of 500 twists / m were braided into a strip to obtain a prefabricated carbon fiber clavicle strip. Three bundles of 12k carbon fiber twisted ropes with a twist of 200 twists / m were braided into a strip, and then spirally wound into a spring through a rod-shaped carbon material mold with 2 coils to obtain a carbon fiber joint prefabricated body. Extend the carbon fiber at both ends of the joint prefabricated body into the carbon fiber at ...

Embodiment 3

[0062] 1) Twisting two bundles of 24k carbon fibers into a carbon fiber rope with a twist of 100 twists / m; then weaving 12 twisted carbon fiber ropes into a strip-shaped continuous carbon fiber braid. The area density is 25g / m2 by needle needle 2 The carbon fiber non-woven fabric is riveted on the two surfaces of the continuous carbon fiber braid to form a sandwich structure, and the riveting point density is 12 points / cm 2 , to obtain the prefabricated body of carbon fiber sternum slice. Two bundles of 24k carbon fiber twisted ropes with a twist of 100 twists / m were braided into a strip to obtain a prefabricated carbon fiber clavicle strip. Two bundles of 24k carbon fiber twisted ropes with a twist of 100 twists / m are braided into strips, and then spirally wound into a spring through a rod-shaped carbon material mold with 2 coils to obtain a carbon fiber joint prefabricated body. Extend the carbon fiber at both ends of the joint prefabricated body into the carbon fiber at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com