Strength detection device for glass processing

A technology for strength detection and glass, which is applied in the direction of measuring devices, strength characteristics, and the use of stable tension/pressure to test the strength of materials, etc. It can solve the problems of inconvenient glass slag cleaning and inconvenient glass placement, so as to improve convenience and improve Sufficiency, safety-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

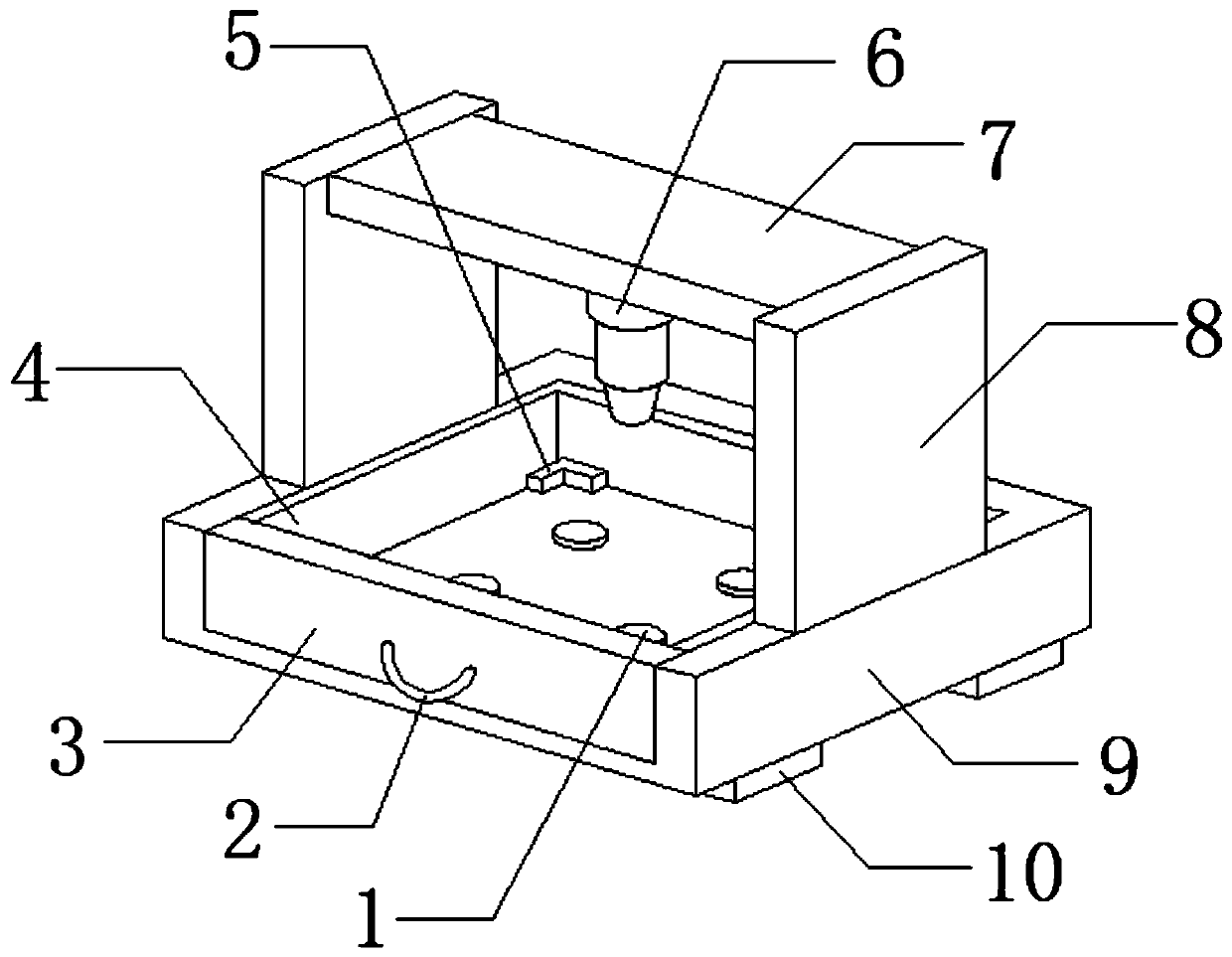

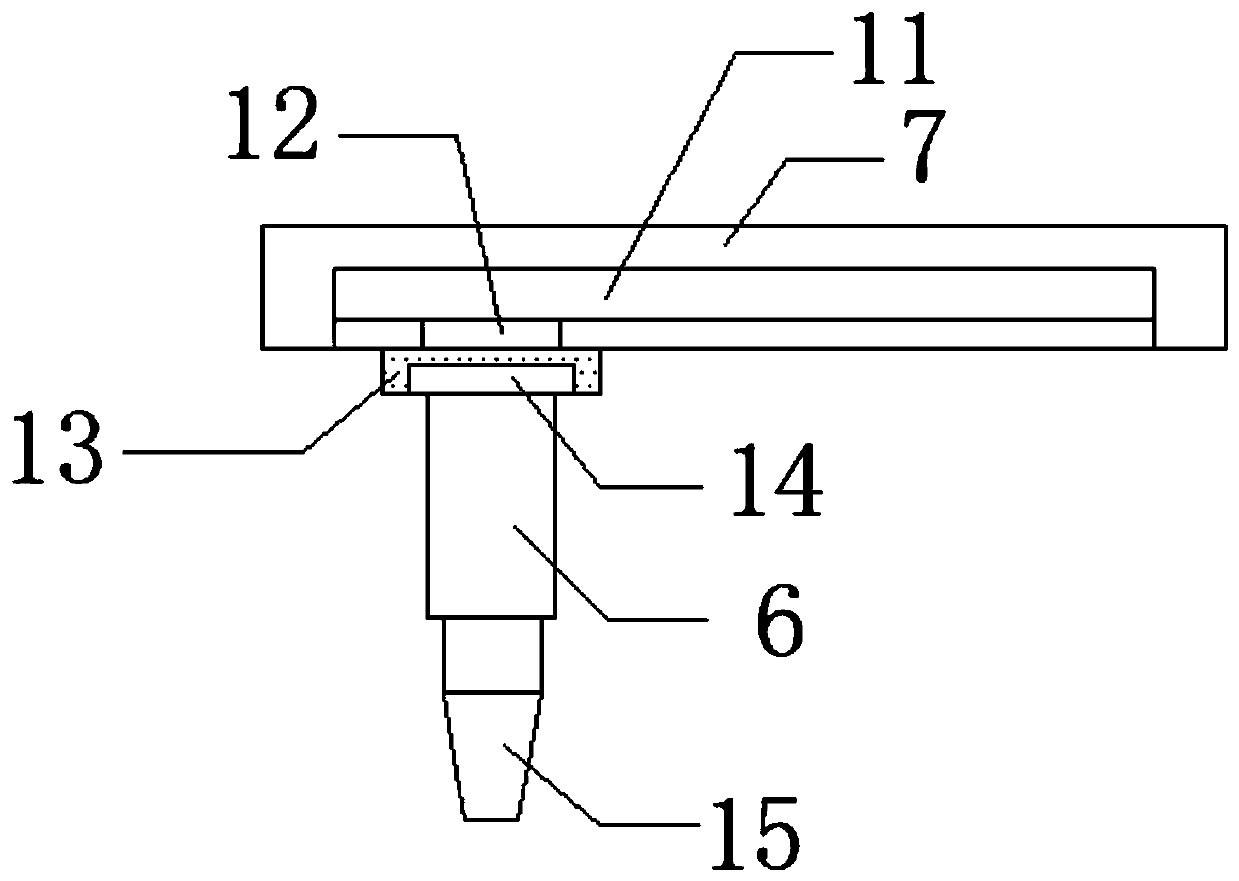

[0024] refer to Figure 1-2 , a strength detection device for glass processing, comprising a support base 9 and four support pads 10, the four support pads 10 are respectively installed on the bottom four-corner outer walls of the support base 9 by bolts, and the outer wall at one end of the top of the support base 9 is provided with a first Groove, and the inner wall of the first groove is plugged with a slot plate 4, the outer wall at one end of the slot plate 4 is connected with the first support plate 3 by bolts, the bottom four corners inner walls of the slot plate 4 are all connected with limited blocks by bolts, the slot plate The bottom inner wall of 4 is connected with four rubber pads 1 distributed in a rectangular array through bolts, and the middle outer wall at one end of the first support plate 3 is connected with a pull handle 2 through a hinge.

[0025] In the present invention, the outer walls on both sides of the top of the support base 9 are connected with v...

Embodiment 2

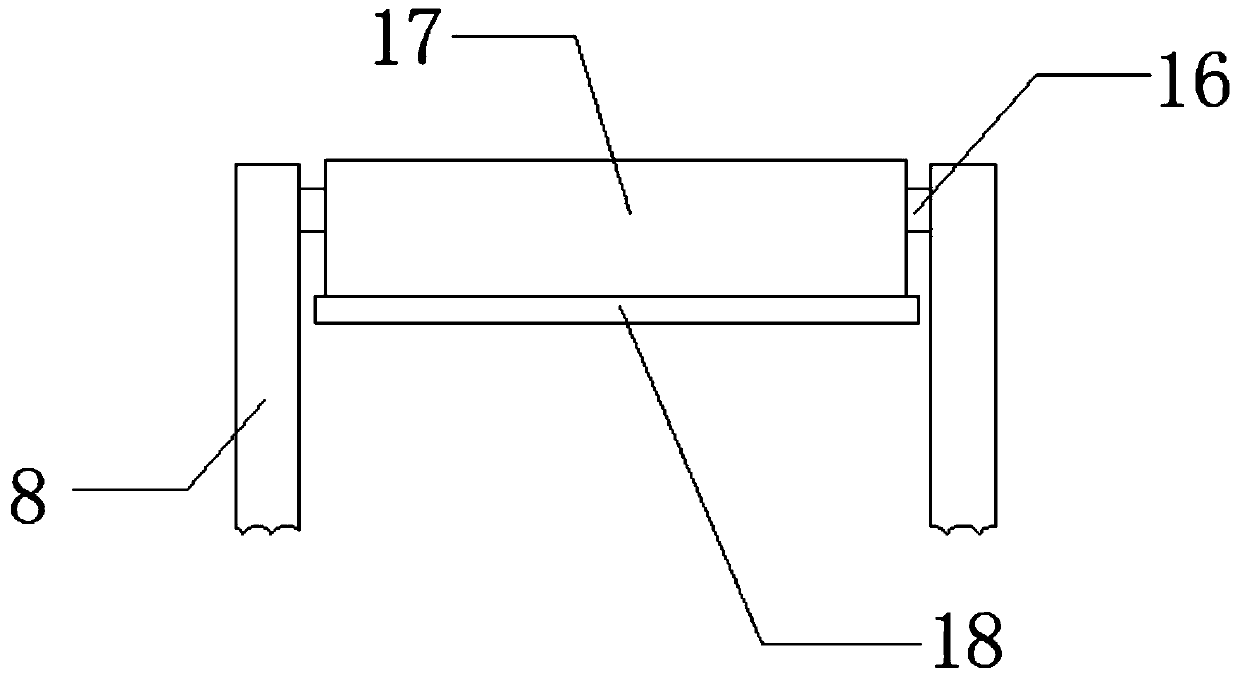

[0027] refer to Figure 1-3 , a strength detection device for glass processing, which also includes the same rotating rod 16 installed on the outer wall of the top and end of the adjacent side of the two splints 8 through bearings, and the peripheral outer wall of the rotating rod 16 is wound with a rolling cloth 17 through a spring , the outer wall of the bottom of the roll cloth 17 is connected with a support rod 18 by bolts. During the process of testing the glass, the roll cloth 17 can be pulled down by the support rod 18, so as to avoid the splash of crushed glass fragments and cause harm to the user. Injury, improve the safety of device use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com