Automated Cutting and Forming Machine for Rigid Carbon Felt

A technology of hard carbon and molding machines, which is applied in the field of carbon felt, can solve the problems of heavy labor, uneven cutting, and low precision of manual cutting, and achieve the effect of high cutting precision and smooth cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

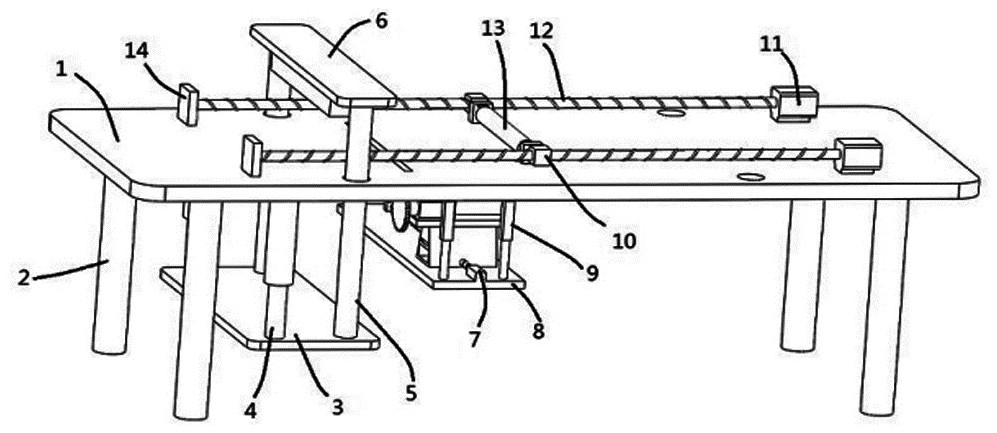

[0027] Example: see Figure 1-5 , an automatic cutting and forming machine for hard carbon felt, including a top plate 1, a cutting mechanism, a pressing mechanism, and a flattening mechanism. The corners of the bottom surface of the top plate 1 are provided with legs 2, and one side of the top plate 1 is along its A cutting hole 15 is set in the width direction, and the cutting mechanism is arranged under the top plate 1 , and the cutting wheel 18 contained in the cutting mechanism moves in the cutting hole 15 to cut off the carbon felt.

[0028] In the present invention, the cutting mechanism includes a second motor 7, a horizontal plate 8, a second electric push rod 9, and a base 17. The horizontal plate 8 is movably arranged under the top plate 1, and a The second electric push rod 9 is connected, the base 17 is slidably arranged on the top surface of the horizontal plate 8, the second motor 7 is fixed on the top surface of the horizontal plate 8, the output shaft of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com