Leather strip cutter

A cutter and leather strap technology, applied in the field of leather strap cutters and cutters for cutting long strips of leather straps for handmade leather goods, can solve the problems of scrapped leather, inability to cut long-distance straps, and different cutting depths to achieve cutting Good molding, simple structure, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

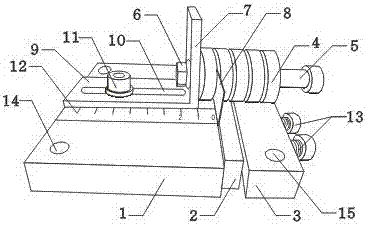

[0019] Such as figure 1 As shown, a leather strap cutter includes a base 1 , a spacer 2 , a block 3 , a distance roller 4 , an installation shaft 5 , a fixing frame 7 and a cutting blade 8 .

[0020] The middle part of base 1 is provided with transverse chute, and fixed frame 7 is " L " type, and the horizontal edge of " L " type is fixed frame horizontal plate 9 , is provided with horizontal sliding groove 10 on fixed frame horizontal plate 9 , slides The slot 10 corresponds to the position of the sliding slot on the base 1 , and an adjusting bolt 11 is arranged on the sliding slot 10 . The fixed frame 7 is fixed on the base 1 through the sliding groove 10 through the adjusting bolt 11, the bottom end of the adjusting bolt 11 is placed in the chute of the base 1, and the outer end of the adjusting bolt 11 is higher than the upper plane where the sliding groove 10 is located. And the outer end of the adjusting bolt 11 is provided with a nut. By loosening the nut and sliding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com