High-speed laying machine

A high-speed technology for laying nets, applied in textiles, papermaking, non-woven fabrics, etc., can solve problems such as wasting energy, increasing equipment investment costs, and complicating structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to be able to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail in the form of examples below, but the description of the examples is not a limitation to the solution of the present invention. Anything made according to the concept of the present invention All equivalent transformations that are merely formal rather than substantive should be regarded as the scope of the technical solution of the present invention.

[0026] In the following description, all concepts related to the directionality or orientation of up, down, left, right, front, and back are based on the position state of the picture being described, so it cannot be understood as a reference to the original The technical solution provided by the invention is particularly limited.

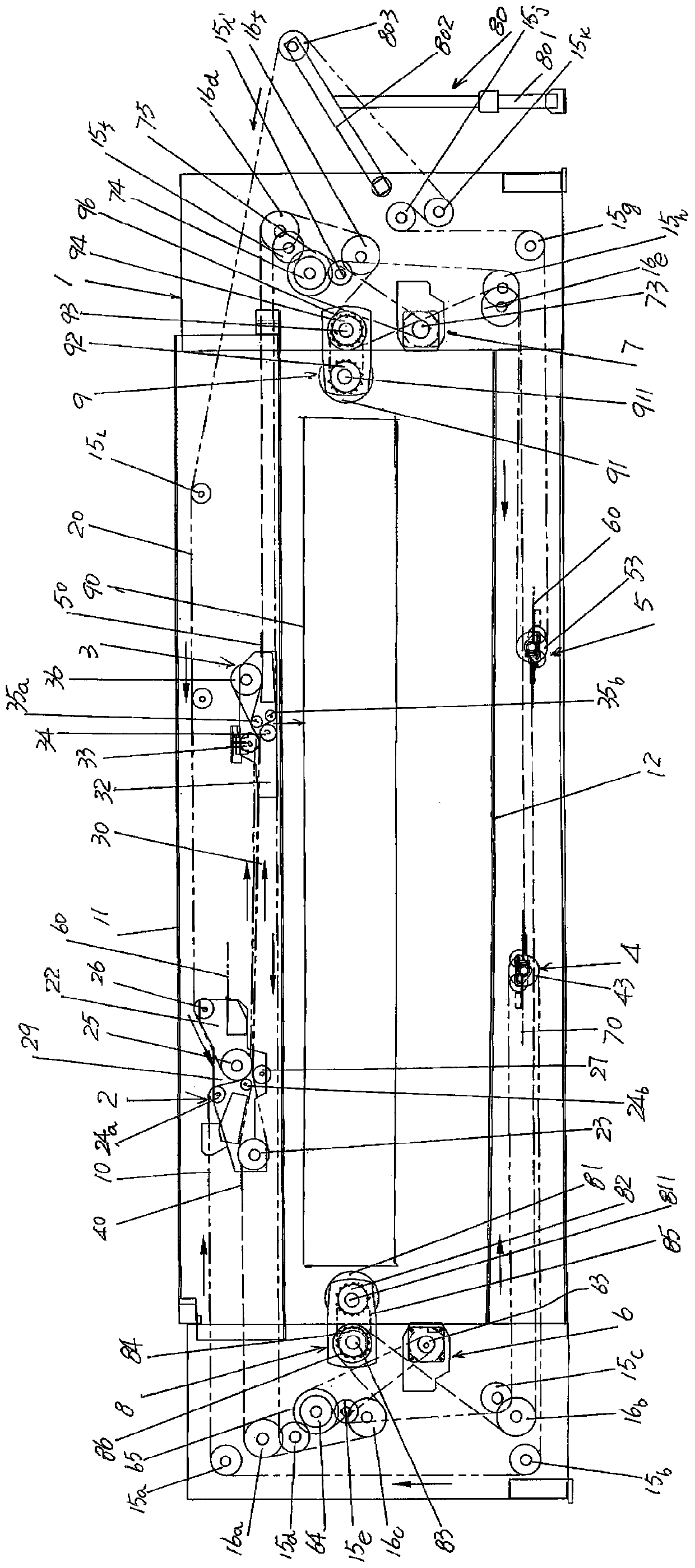

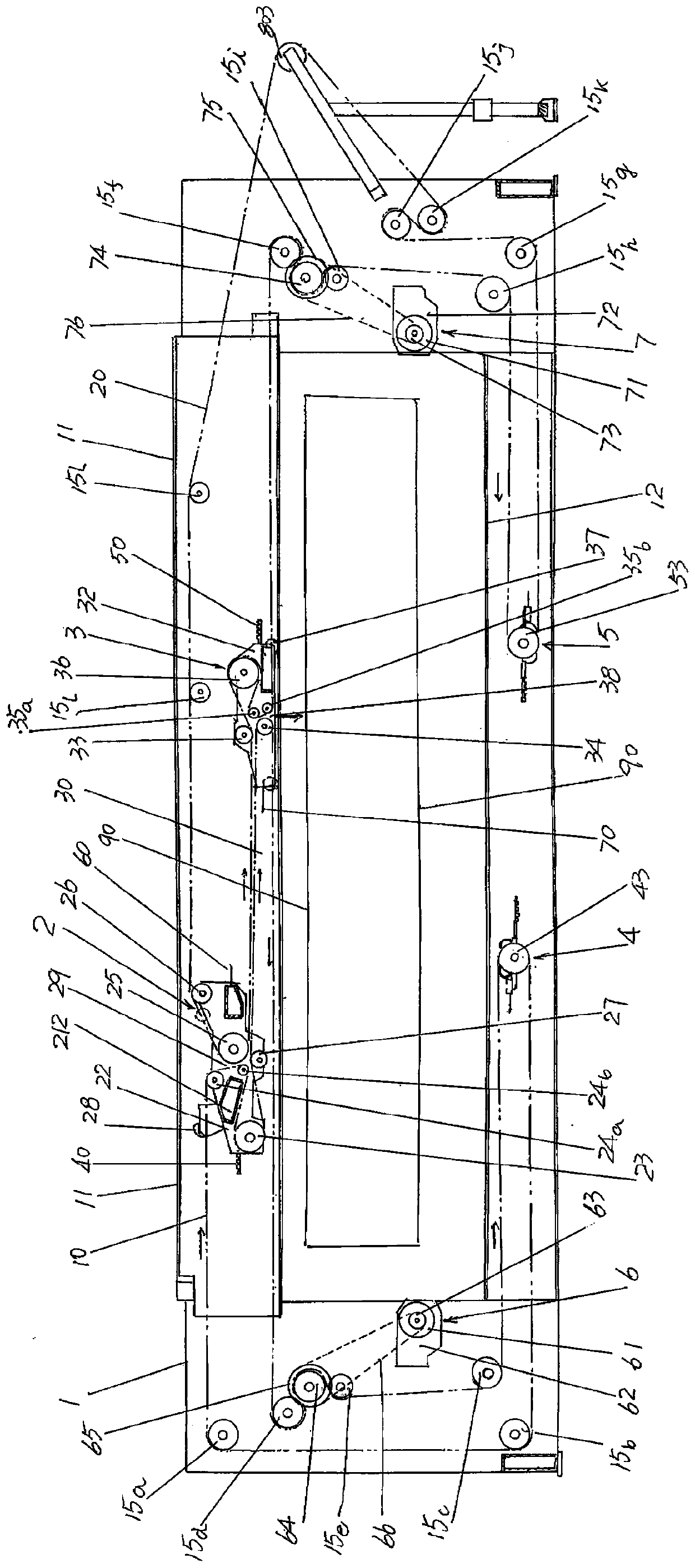

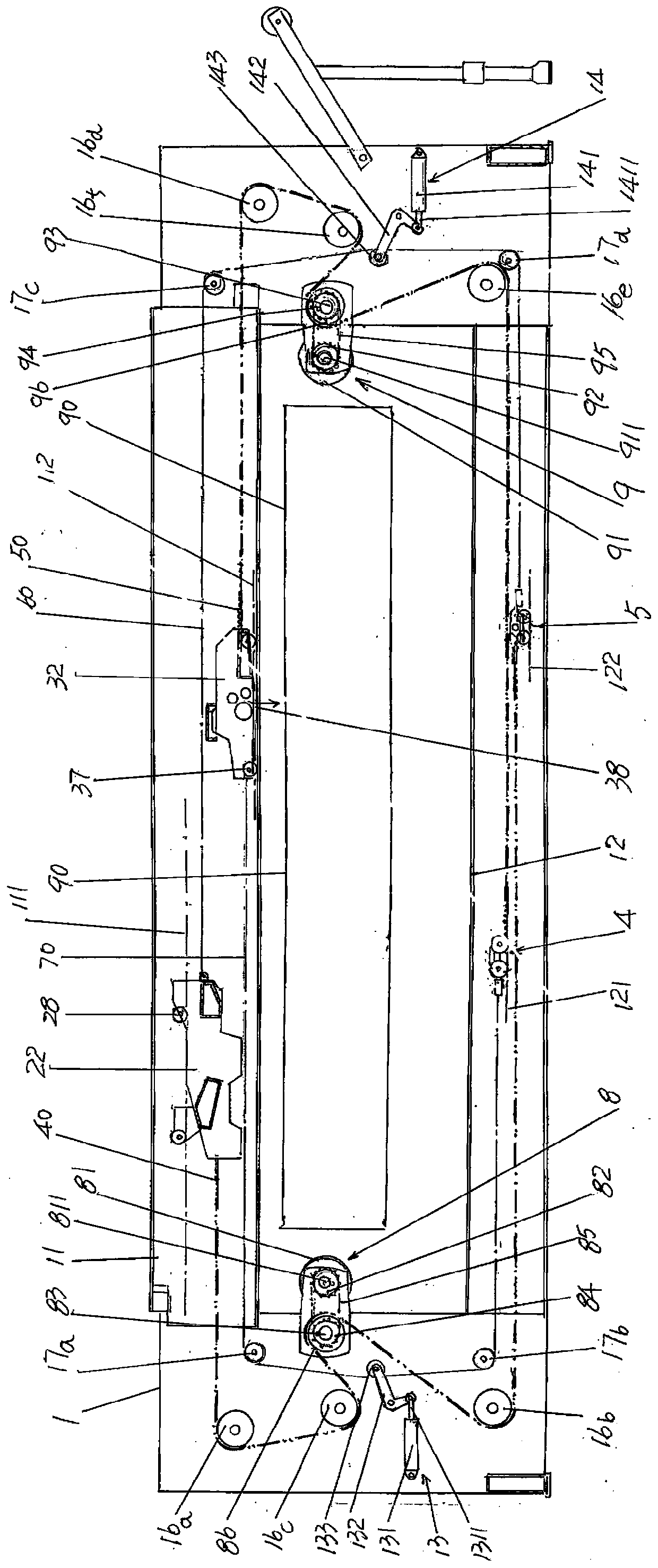

[0027] See Figure 1 to Figure 3 , Shows a frame 1, the upper part of the frame 1 has a pair of frame upper beams 11, and the lower part has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com