Nanocrystalline magnetically soft alloy, amorphous magnetically soft alloy and preparation methods of nanocrystalline magnetically soft alloy and amorphous magnetically soft alloy

A nanocrystalline soft magnetic and soft magnetic alloy technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of poor high-frequency magnetic properties and low amorphous formation ability, so as to improve toughness and improve amorphous Formability, high-quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

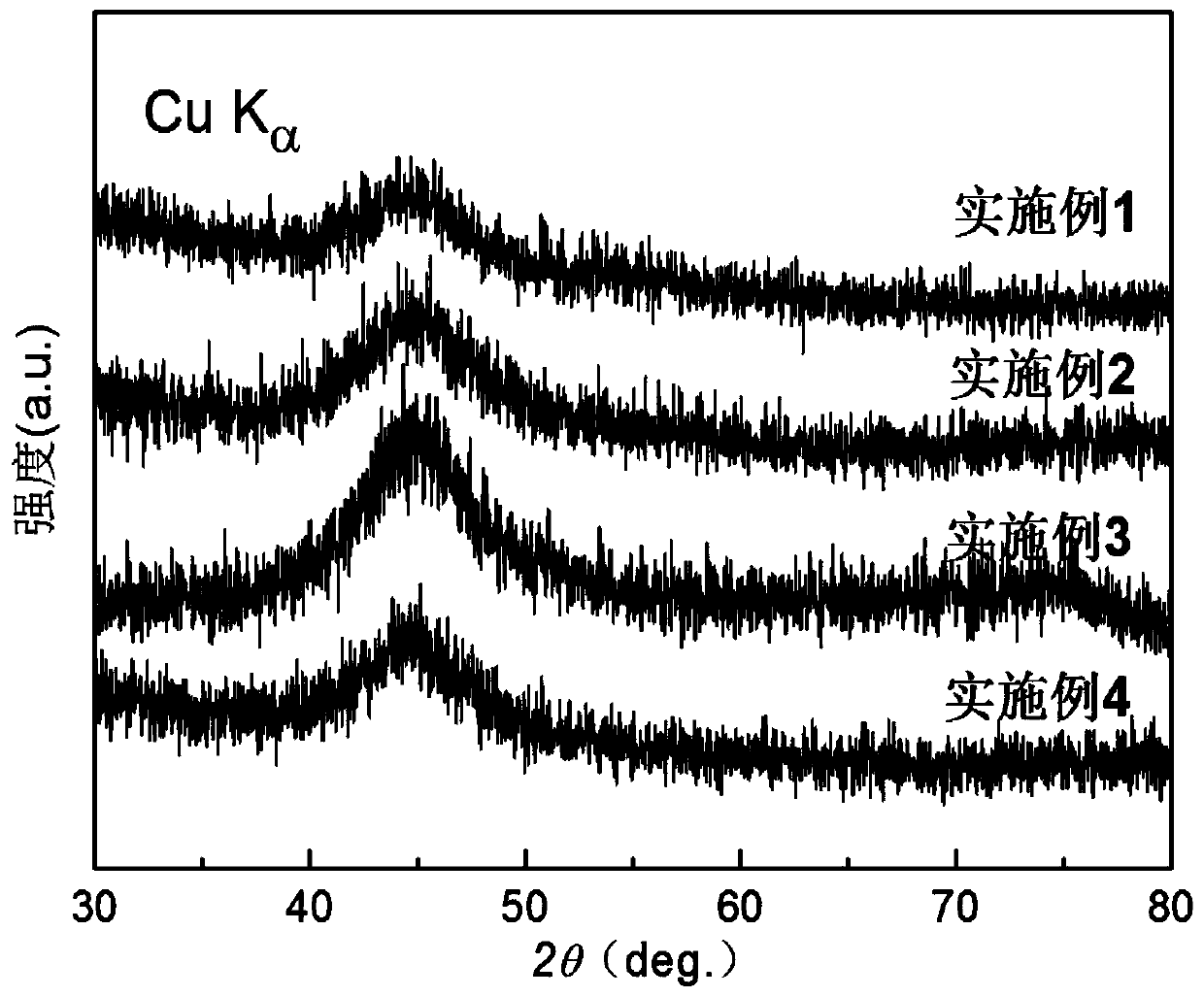

Embodiment 1

[0110] This embodiment provides a nanocrystalline soft magnetic alloy, its composition and atomic percentage are: Fe74.9at%, Mn 1at%, Cr 0.1at%, Cu 1at%, Si 18at%, B 4at%, Nb 1at %, that is, the molecular formula is Fe 74.9 mn 1 Cr 0.1 Cu 1 Si 18 B 4 Nb 1 .

[0111] The preparation method of nanocrystalline soft magnetic alloy comprises the following steps:

[0112] 1) Mix iron raw materials, manganese raw materials, chromium-containing alloy ingots, copper raw materials, silicon raw materials, boron-iron pre-alloyed ingots and niobium-iron pre-alloyed ingots according to the atomic percentage of the above-mentioned nanocrystalline soft magnetic alloy, and heat at 1200 ° C 60min, obtain high-temperature alloy molten steel;

[0113] 2) The high-temperature alloy molten steel is sprayed onto a 30m / s rotating copper roller through a nozzle of a certain shape by a melt quenching method to obtain an amorphous strip; the width of the amorphous strip is 100 mm, and the thickn...

Embodiment 2

[0116] This embodiment provides a nanocrystalline soft magnetic alloy, its composition and atomic percentage are: Fe74.5at%, Mn0.5at%, Cr1at%, Cu0.8at%, Si16.5at%, B5.5at% , Nb 1.2at%, that is, the molecular formula is Fe 74.5 mn 0.5 Cr 1 Cu 0.8 Si 16.5 B 5.5 Nb 1.2 .

[0117] The preparation method of nanocrystalline soft magnetic alloy comprises the following steps:

[0118] 1) Mix iron raw materials, manganese raw materials, chromium-containing alloy ingots, copper raw materials, silicon raw materials, boron-iron pre-alloyed ingots and niobium-iron pre-alloyed ingots according to the atomic percentage of the above-mentioned nanocrystalline soft magnetic alloy, and heat at 1400 ° C 20min, obtain high-temperature alloy molten steel;

[0119] 2) The high-temperature alloy molten steel is sprayed onto a 30m / s rotating copper roller through a nozzle of a certain shape by a melt quenching method to obtain an amorphous strip; the width of the amorphous strip is 10 mm, and ...

Embodiment 3

[0122] This embodiment provides a nanocrystalline soft magnetic alloy, its composition and atomic percentage are: Fe 74at%, Mn 2at%, Cu 1at%, Si 13at%, B 8at%, Nb 2at%, that is, the molecular formula is Fe 74 mn 2 Cu 1 Si 13 B 8 Nb 2 .

[0123] The preparation method of nanocrystalline soft magnetic alloy comprises the following steps:

[0124] 1) Mix iron raw materials, manganese raw materials, copper raw materials, silicon raw materials, boron-iron pre-alloyed ingots and niobium-iron pre-alloyed ingots according to the atomic percentage of the above-mentioned nanocrystalline soft magnetic alloy, and heat at 1350 ° C for 30 minutes to obtain a superalloy molten steel;

[0125] 2) The high-temperature alloy molten steel is sprayed onto a 30m / s rotating copper roller through a nozzle of a certain shape by a melt quenching method to obtain an amorphous strip; the width of the amorphous strip is 40 mm, and the thickness is 20 μm ;

[0126] 3) The nanocrystalline soft magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com