A method for improving the high-frequency magnetic permeability of fe-based nanocrystalline soft magnetic alloy

A nanocrystalline soft magnetic and magnetic permeability technology, applied in magnetic objects, magnetic materials, furnaces, etc., can solve problems such as the inability to meet high magnetic permeability, and achieve outstanding comprehensive soft magnetic properties, excellent magnetic permeability, and reduced manufacturing. effect with cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Fe 73.5 Si 14 B 8 Cu 1 Nb 3 C 0.5

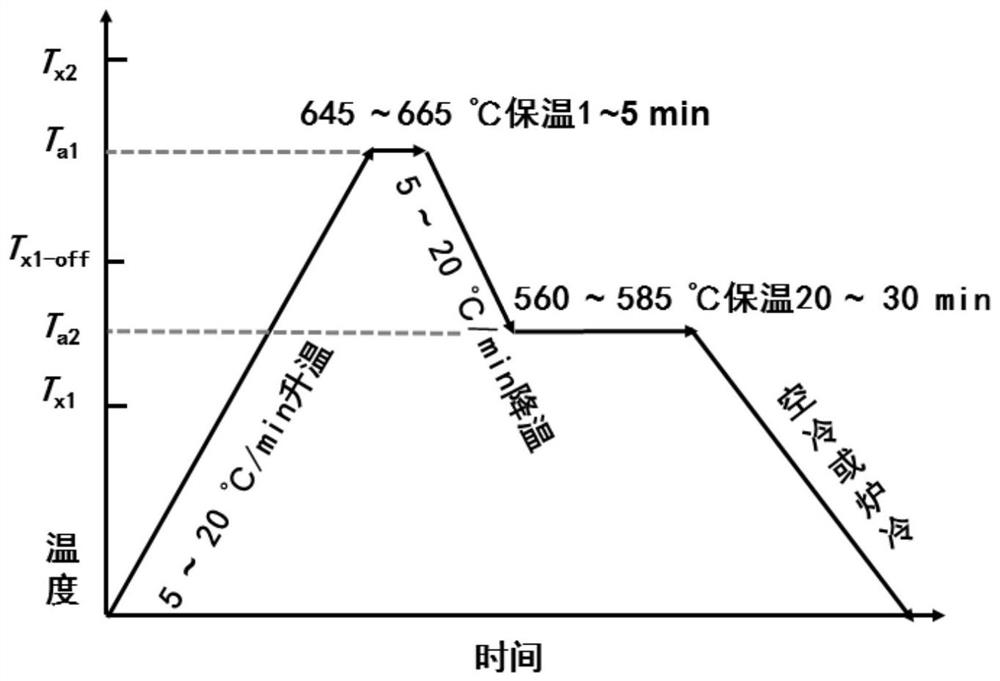

[0050] When preparing the Fe-based nanocrystalline soft magnetic alloy described in this implementation, it mainly includes the following steps:

[0051] Step 1, using Fe, Si, B, Cu, Nb and FeC alloy raw materials with a purity greater than 99% by mass to carry out weighing and batching according to the nominal composition of the alloy;

[0052] Step 2, mixing the weighed raw materials, using a non-consumable electric arc furnace to prepare a master alloy ingot under an Ar gas atmosphere, and repeatedly smelting the alloy for 4 times to ensure that the composition of the master alloy ingot is uniform;

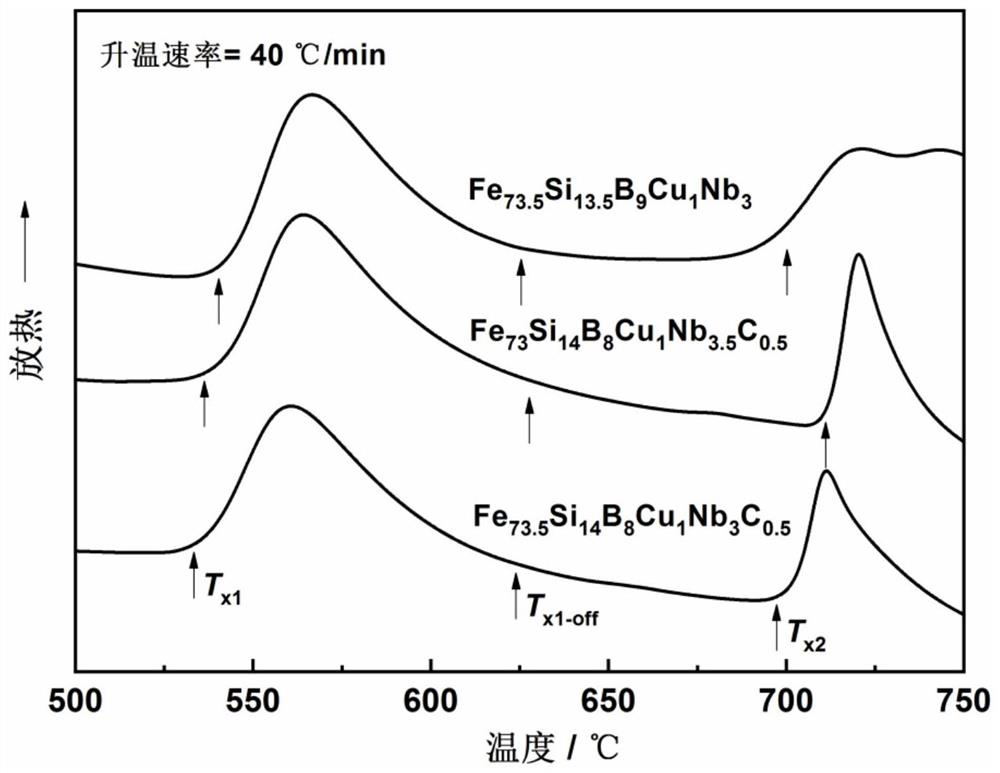

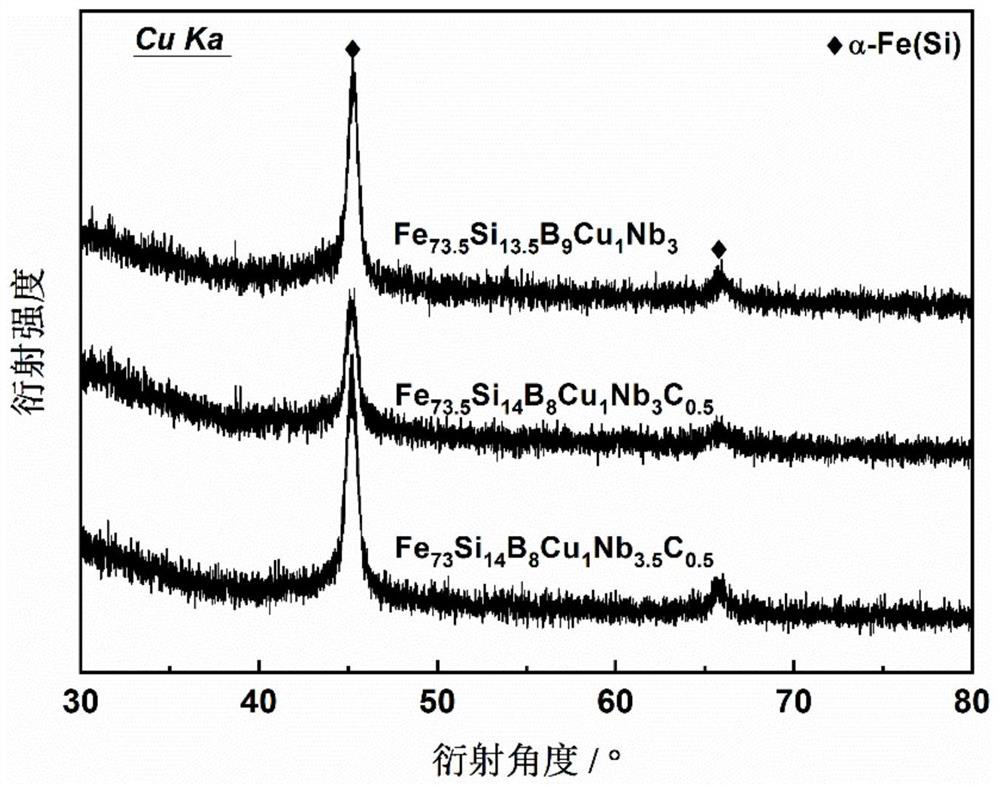

[0053] Step 3: crush the master alloy ingot and put it into a quartz tube, and use a single-roll strip stripping process to strip the strip at a speed of 40m / s under an Ar gas atmosphere to obtain a quenched alloy with a width of 1.5mm and a thickness of 30μm As for the strip, the X-ray diffractometer (XRD) was used t...

Embodiment 2

[0058] Example 2: Fe73.5 Si 14.25 B 8 Cu 1 Nb 3 C 0.25

[0059] When preparing the Fe-based nanocrystalline soft magnetic alloy described in this implementation, steps 1, 2, and 3 are the same as in Example 1, and the quenched alloy strip is determined to be a complete amorphous structure by XRD, and the T is measured by DSC. x1 , T x1-off and the second crystallization initiation temperature T x2 They are 531°C, 615°C and 696°C, respectively. According to determine T a1 The interval is 630~680℃, T a2 The interval is 540~610℃;

[0060] Step 4 is the same as in Example 1, but the adjustment heat treatment process parameter is: H r =10°C / min, T a1 =650°C, t a1 = 3min; C r =10°C / min, T a2 =560°C, t a2 = 25 min.

[0061] Test the magnetic properties of the nanocrystalline alloy strip after heat treatment, its μ at the frequency of 10kHz and 100kHz e 32900 and 22800 respectively, H c 1.8A / m, B s It is 1.25T. Further experiments to determine the allowable T a2 T...

Embodiment 3

[0062] Example 3: Fe 73.5 Si 13.75 B 8 Cu 1 Mo 3 C 0.75

[0063] When preparing the Fe-based nanocrystalline soft magnetic alloy described in this implementation, it mainly includes the following steps:

[0064] Step 1, using Fe, Si, B, Cu, Mo and FeC alloy raw materials with a purity greater than 99% by mass to carry out weighing and batching according to the alloy composition;

[0065] Step two, three are identical with embodiment 1, and measure quenching alloy strip by XRD and be completely amorphous structure, measure T by DSC x1 , T x1-off and the second crystallization initiation temperature T x2 They are 530°C, 626°C and 680°C, respectively. According to determine T a1 The interval is 630~660℃, T a2 The interval is 540~620℃;

[0066] Step 4 is the same as in Example 1, but the adjustment heat treatment process parameter is: H r =5°C / min, T a1 =645°C, t a1 = 1min; C r =5°C / min, T a2 =580°C, t a2 = 20 min.

[0067] Test the magnetic properties of the na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com