Rolling process tobacco sheet raw material and preparation method thereof

A technology of tobacco flakes and rolling method, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment. It can solve the problems of difficult crushing, multiple types of raw materials, and a wide range of sources, and achieve improved flavor, uniform and stable specifications, and improved quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

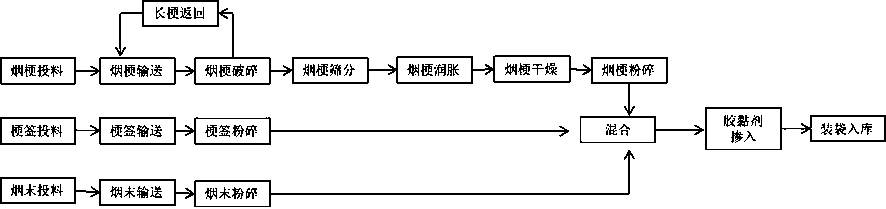

[0036] A method for preparing tobacco sheet raw materials by rolling method of the present invention, according to the classification of raw materials, tobacco stems, stem sticks, and tobacco powders are classified and processed, so that the materials before mixing are homogenized and the specifications are more uniform and stable, which solves the problem of rolling. Tobacco flakes have many types of raw materials, a wide range of sources, difficulty in crushing, and uneven texture, which improves the quality of tobacco flakes and improves the taste of tobacco flakes.

[0037] The embodiment of the present invention also provides a tobacco sheet raw material prepared by a method for preparing tobacco sheet raw material by rolling method, including the following raw materials in parts by mass: 25-100 parts of tobacco stems, 25-100 parts of stem sticks, and 25-100 parts of tobacco powder , 3~30 parts of adhesive.

[0038] Preferably, the tobacco stems are thick strips with a le...

Embodiment 1

[0041] Embodiment 1 of the present invention provides a kind of preparation method of rolling tobacco sheet raw material, comprises the following steps:

[0042] (1) Tobacco stems with a length of 20-100mm and a width of 2-10mm are sequentially fed, conveyed, and broken into pieces with a size of less than 8mm×20mm, and then soaked in dry ice to swell, and dried by a drum until the pieces contain water After the rate is about 8%, it is crushed and processed into 100-120 mesh tobacco stem scraps;

[0043] (2) The stem sticks with a length of 5~20mm and a width of 0.5~2mm are sequentially fed, conveyed, and crushed into 100-120 mesh stem sticks;

[0044] (3) The tobacco powder with a particle size of 0.3~1mm is sequentially fed, conveyed, and crushed into 100~120 mesh tobacco powder fragments;

[0045] (4) Mix the above-mentioned tobacco stem scraps, stem stick scraps, tobacco powder scraps, and adhesives according to the formula requirements to make tobacco sheet raw materials...

Embodiment 2

[0047] Embodiment 2 of the present invention provides a method for preparing tobacco sheet raw material by rolling method, comprising the following steps:

[0048] (1) Tobacco stems with a length of 20-100mm and a width of 2-10mm are sequentially fed, conveyed, and broken into pieces with a size of less than 8mm×20mm, and then soaked in dry ice to swell, and dried by a drum until the pieces contain water After the rate is about 5%, it is crushed and processed into 80-100 mesh tobacco stem scraps;

[0049] (2) The stem sticks with a length of 5~20mm and a width of 0.5~2mm are sequentially fed, conveyed, and crushed into 80-100 mesh stem sticks;

[0050] (3) The tobacco powder with a particle size of 0.3~1mm is sequentially fed, conveyed, and crushed into 80~100 mesh powdered tobacco powder;

[0051] (4) Mix the above-mentioned tobacco stem scraps, stem stick scraps, tobacco powder scraps, and adhesives according to the formula requirements to make tobacco sheet raw materials, am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com