Dilute chemical solution production device

A technology for manufacturing devices and liquid medicines, which is applied in distribution devices, feeding devices, liquid distribution, transportation or transfer devices, etc., and can solve problems such as complicated device structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

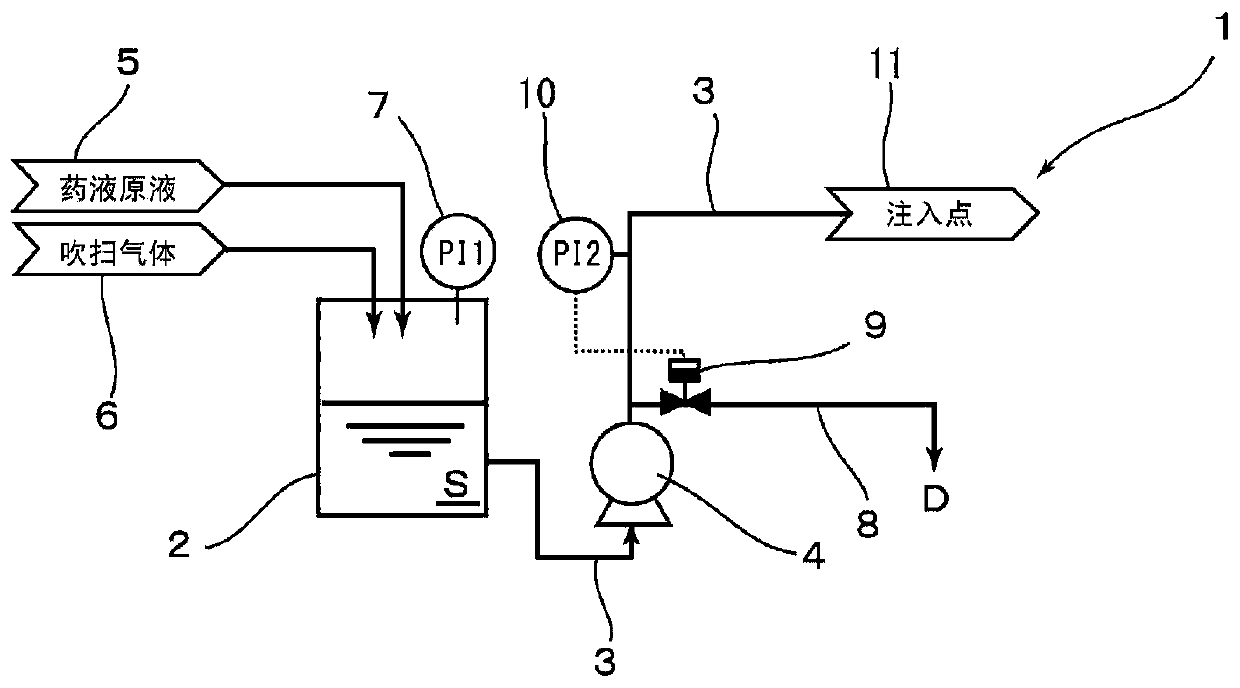

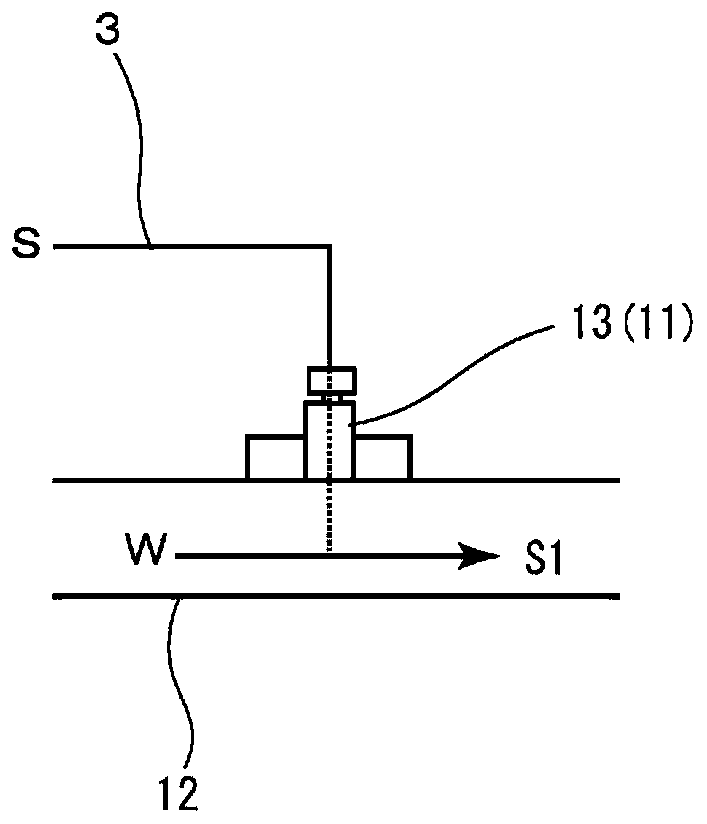

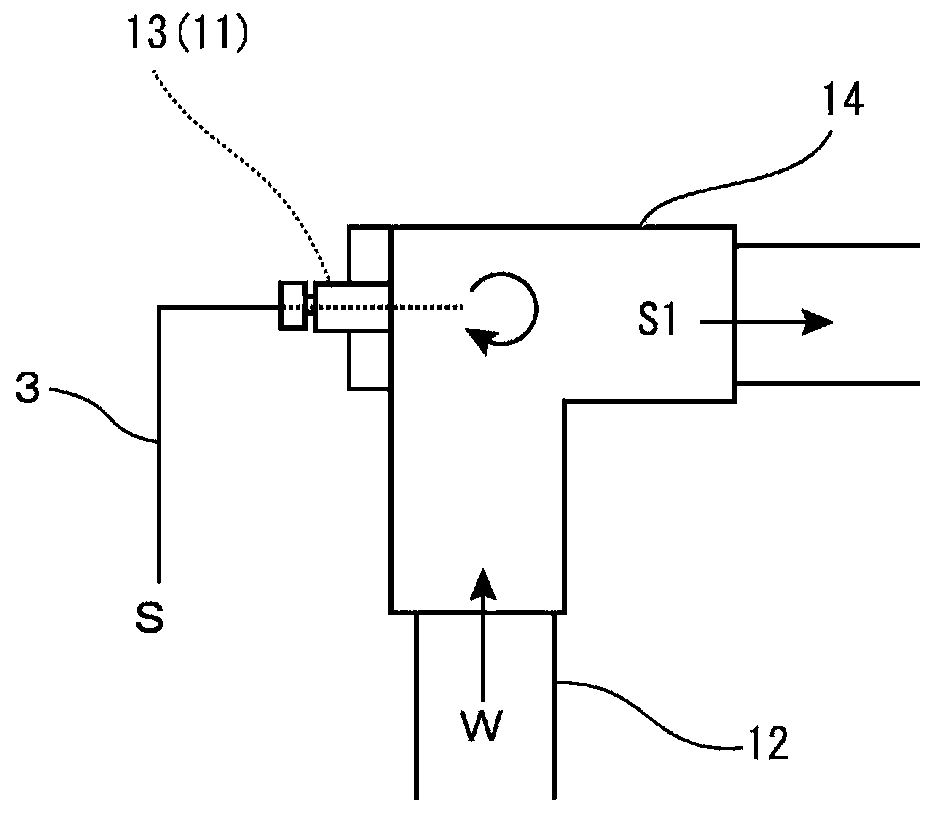

[0056] use figure 1 with figure 2 The shown diluted chemical solution manufacturing apparatus 1 produces diluted ammonia water S1 as the chemical solution S using a 29% ammonia solution as a stock solution.

[0057] In this dilute chemical solution manufacturing device 1, the flow rate of ultrapure water W is 13.2L / min and its variation is within the flow deviation range of 12.0L / min to 14.5L / min, and the set concentration of ammonia is determined as 2ppm. According to this super The flow rate of the pure water W is such that the injection rate from the plunger pump 4 is 0.092 mL / min to 0.111 mL / min to supply the ammonia stock solution S.

[0058] The result of continuously measuring the concentration of ammonia dilute chemical solution S1 in this dilute chemical solution manufacturing apparatus 1 for 1 hour is shown together with the flow rate of ultrapure water W in Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com