Preparation method and application of double-sided oleophobic superhydrophobic-superhydrophilic janus material

A super-hydrophobic and super-hydrophilic technology, applied in the direction of fiber type, liquid-repellent fiber, fiber treatment, etc., can solve the problem of not having double-sided oleophobicity, and achieve superior washing resistance, short operation process, and firmness high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

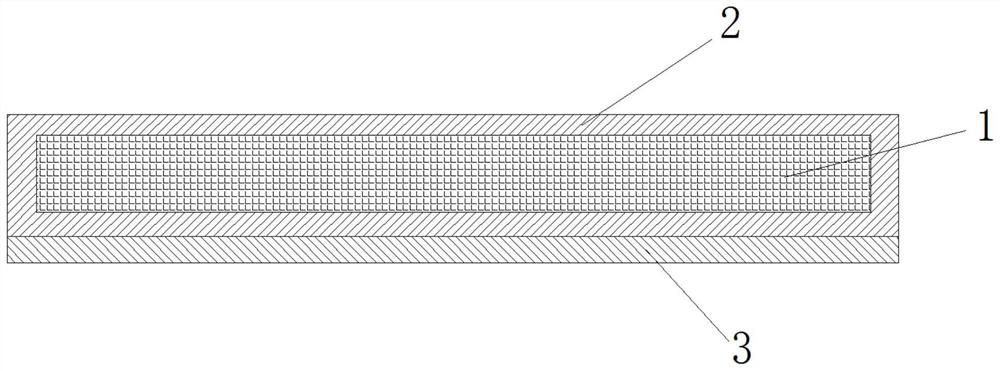

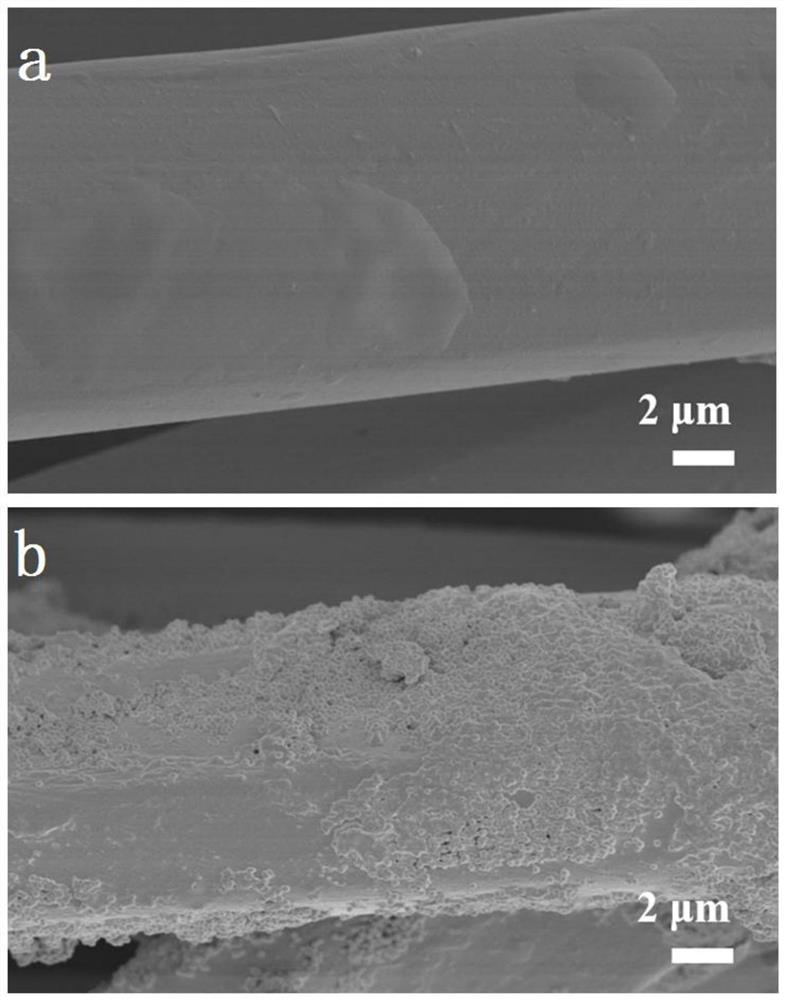

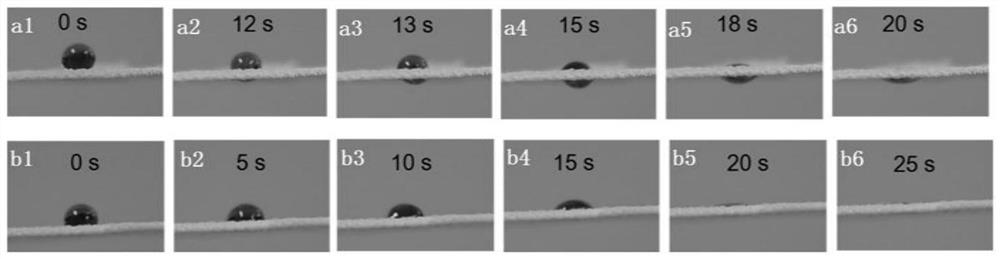

[0057] A double-sided oleophobic superhydrophobic-superhydrophilic Janus-type fabric, such as figure 1 As shown, it includes a substrate 1, the surface of the substrate 1 is coated with a hydrophilic-oleophobic layer 2, and a surface of one side of the hydrophilic-oleophobic layer 2 is sprayed with a hydrophobic-oleophobic layer 3. The substrate 1 is polyester fabric.

[0058] The preparation method of the above-mentioned double-sided oleophobic superhydrophobic-superhydrophilic Janus fabric, the specific steps are:

[0059] (1) adding photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-acetone into the mixed solution of hydrophilic monomer methacrylic acid, POSS acrylate and perfluorohexyl ethyl acrylate, wherein, The mass ratio of methacrylic acid to POSS acrylate was 50:1, the mass ratio of methacrylic acid to perfluorohexylethyl acrylate was 5:2, and the solution was stirred at 25° C. for 10 min to obtain a modified monomer solution. Acetone was used as a solvent, mixed with th...

Embodiment 2

[0065] A preparation method of a double-sided oleophobic superhydrophobic-superhydrophilic Janus fabric, the specific steps are:

[0066] (1) adding photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-acetone into the mixed solution of hydrophilic monomer methacrylic acid, POSS acrylate and perfluorohexyl ethyl acrylate, wherein, The mass ratio of methacrylic acid to POSS acrylate was 50:1, the mass ratio of methacrylic acid to perfluorohexylethyl acrylate was 5:2, and the solution was stirred at 25° C. for 10 min to obtain a modified monomer solution. Acetone was used as a solvent, mixed with the above solution in a volume ratio of 3:1, and stirred at 25 °C for 10 min to obtain a hydrophilic-oleophobic modified solution. The photoinitiator accounted for 3wt% of the total mass of the modified monomer solution.

[0067] (2) Immerse the 5cm×5cm polyester fabric in the hydrophilic-oleophobic modified solution for 1-10min, remove the excess solution, and place it in the UV light curing a...

Embodiment 3

[0075] A preparation method of a double-sided oleophobic superhydrophobic-superhydrophilic Janus fabric, the specific steps are:

[0076] (1) adding photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-acetone into the mixed solution of hydrophilic monomer methacrylic acid, POSS acrylate and perfluorohexyl ethyl acrylate, wherein, The mass ratio of methacrylic acid to POSS acrylate was 50:1, the mass ratio of methacrylic acid to perfluorohexylethyl acrylate was 5:2, and the solution was stirred at 25° C. for 10 min to obtain a modified monomer solution. Acetone was used as a solvent, mixed with the above solution in a volume ratio of 3:1, and stirred at 25 °C for 10 min to obtain a hydrophilic-oleophobic modified solution. The photoinitiator accounted for 3wt% of the total mass of the modified monomer solution.

[0077] (2) Immerse the 5cm×5cm polyester fabric in the hydrophilic-oleophobic modified solution for 1-10min, remove the excess solution, and place it in the UV light curing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com