A strain of Streptomyces producing ε-polylysine and its application

A technology of polylysine and Streptomyces alba, applied in the field of bioengineering, can solve the problems of unsuitable breeding work, high price, general screening effect, etc., and achieve the effect of excellent passage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: the breeding of Streptomyces parvus M-Z18

[0049] Bettner solid medium: 2% glucose, 0.2% yeast extract, 0.4% peptone, 2% agar, all in mass-volume fraction, pH 7.5, sterilized at 115°C for 20min.

[0050] Solid medium with succinic acid as carbon source: 2% succinic acid, 0.2% yeast extract, 0.4% peptone, 2% agar, all in mass-volume fraction, pH 7.5, sterilized at 115°C for 20 minutes.

[0051] Specific steps are as follows:

[0052] (1) Evenly spread 10-100 μL of spore suspension prepared by the wild fungus Streptomyces albicans Z-18 screened in the soil on a metal slide cooled by flame burning, and place in a normal temperature and pressure plasma (ARTP) mutagenesis system Operation (instrument power 100W, gas flow 10SLM) for 50-400s;

[0053] (2) Inoculate the spores of the wild fungus Z-18 treated in step (1) on the Bethner solid slant medium, and after cultivating at a constant temperature of 30°C for 5-8 days, suspend the spores in 5mL of phosphate...

Embodiment 2

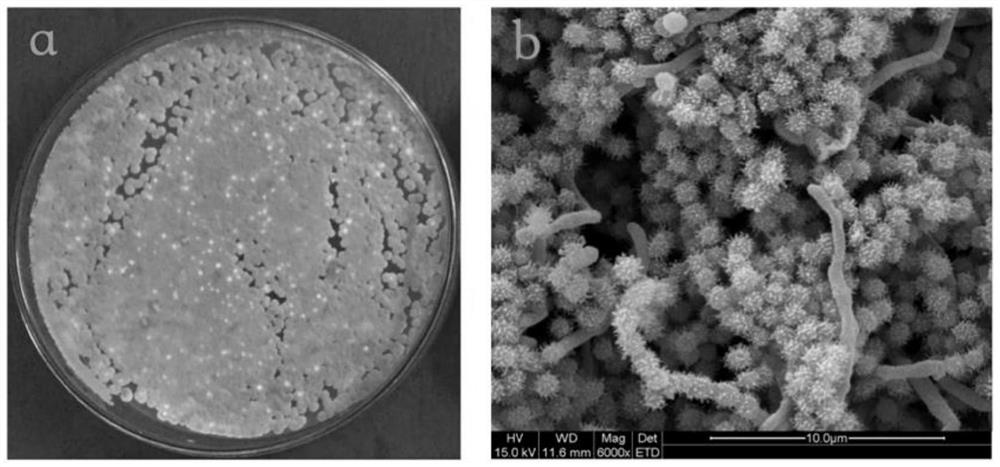

[0067] Embodiment 2: Morphological characteristics of starting bacterium Z-18 and mutagenic Streptomyces albicans M-Z18

[0068] Through the identification of microbial morphological characteristics and physical and chemical characteristics, the characteristics of the starting strain Z-18 and the mutagenic strain M-Z18 were compared, as follows:

[0069] 1. Morphological characteristics

[0070] The aerial hyphae of the strain Z-18 grew well on the medium containing yeast extract or peptone, the spores were curvy, the spores were light gray chains, and were oval under the microscope; the colonies and their backs were yellow.

[0071] The aerial hyphae of the strain M-Z18 grow well on the peptone yeast extract medium, the spore filaments are spiral or wavy, and the spores are dark gray chains, which are oval under the microscope; the colonies and their backs are yellow or yellow brown.

[0072] 2. Cultivate characteristics

[0073] Culture at a constant temperature of 30°C f...

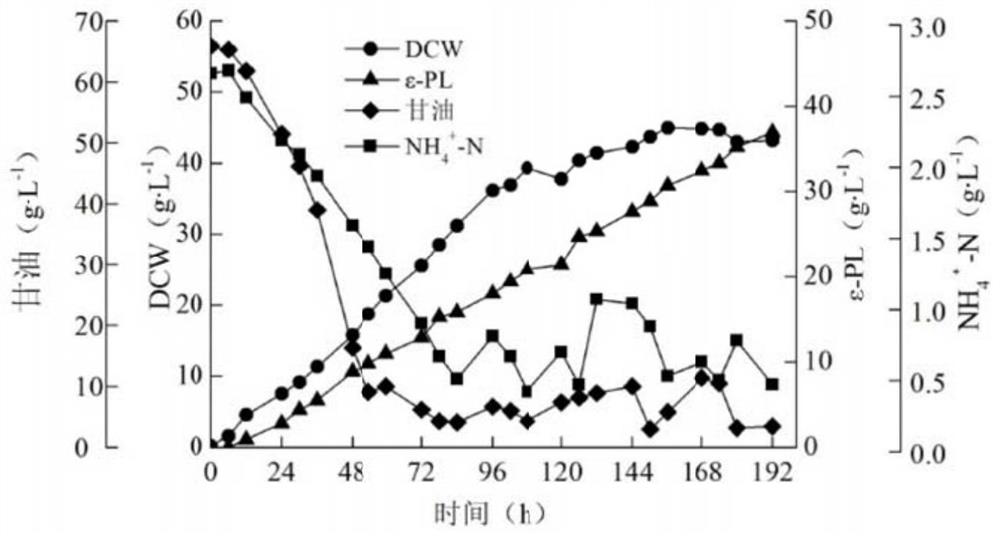

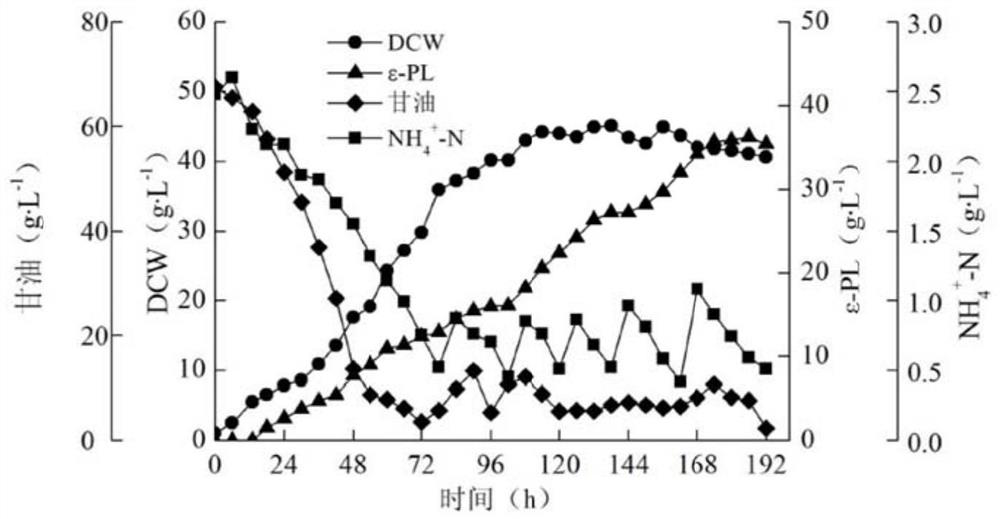

Embodiment 3

[0087] M3G seed medium: glucose 5%, (NH 4 ) 2 SO 4 1%, Na 2 HPO 4 0.14%, KH 2 PO 4 0.1%, MgSO 7 ·H 2 O 0.025%, ZnSO 7 ·H 2 O 0.005%, FeSO 7 ·H 2 O 0.001%, yeast powder 0.5%, pH 6.8, sterilized at 115°C for 20min.

[0088] RSM liquid fermentation medium: glycerol 6%, (NH 4 ) 2 SO 4 0.5%, beef extract 1%, KH 2 PO 4 0.4%, MgSO 4 0.08%, FeSO 4 0.005%, all are mass-volume fractions, sterilized at 115°C for 20 minutes, and fermented at natural pH.

[0089] The purified M-Z18 spores were inoculated into the seed medium filled with M3G, and cultured in shake flasks at 30° C.×200 rpm for 24 hours to prepare seed liquid. The seed solution was inoculated in the RSM fermentation medium with an inoculation amount of 8%, and the shake flask was fermented for 72 hours. The content of ε-PL in the fermentation supernatant of the mutant strain detected by methyl orange detection method was 1.8g / L, and the production efficiency of the strain was 0.45g / L / d. The cell mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com