Electronic chip heat dissipation experiment device based on film evaporation

A technology for electronic chips and experimental devices, applied in electrical components, structural parts of electrical equipment, cooling/ventilation/heating transformation, etc. Heat dissipation, small size and other issues, to achieve the effect of light weight, simple structure and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below:

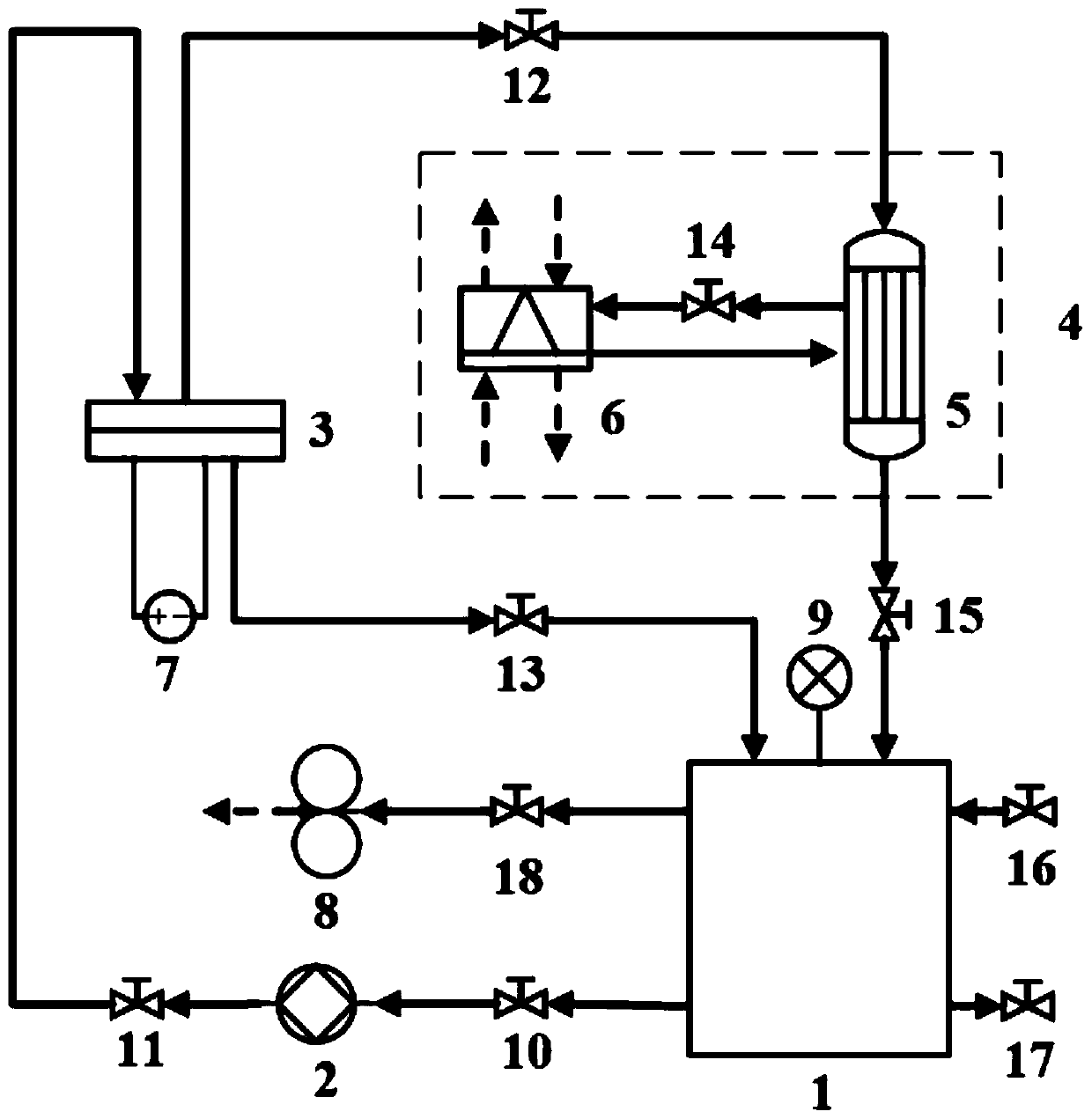

[0037] A cooling and heat dissipation device for electronic chips based on thin film evaporation includes a thin film evaporation generator 3, a liquid storage tank 1, a piezoelectric micropump 2, a temperature control device 4, and pipes and valves connecting various components.

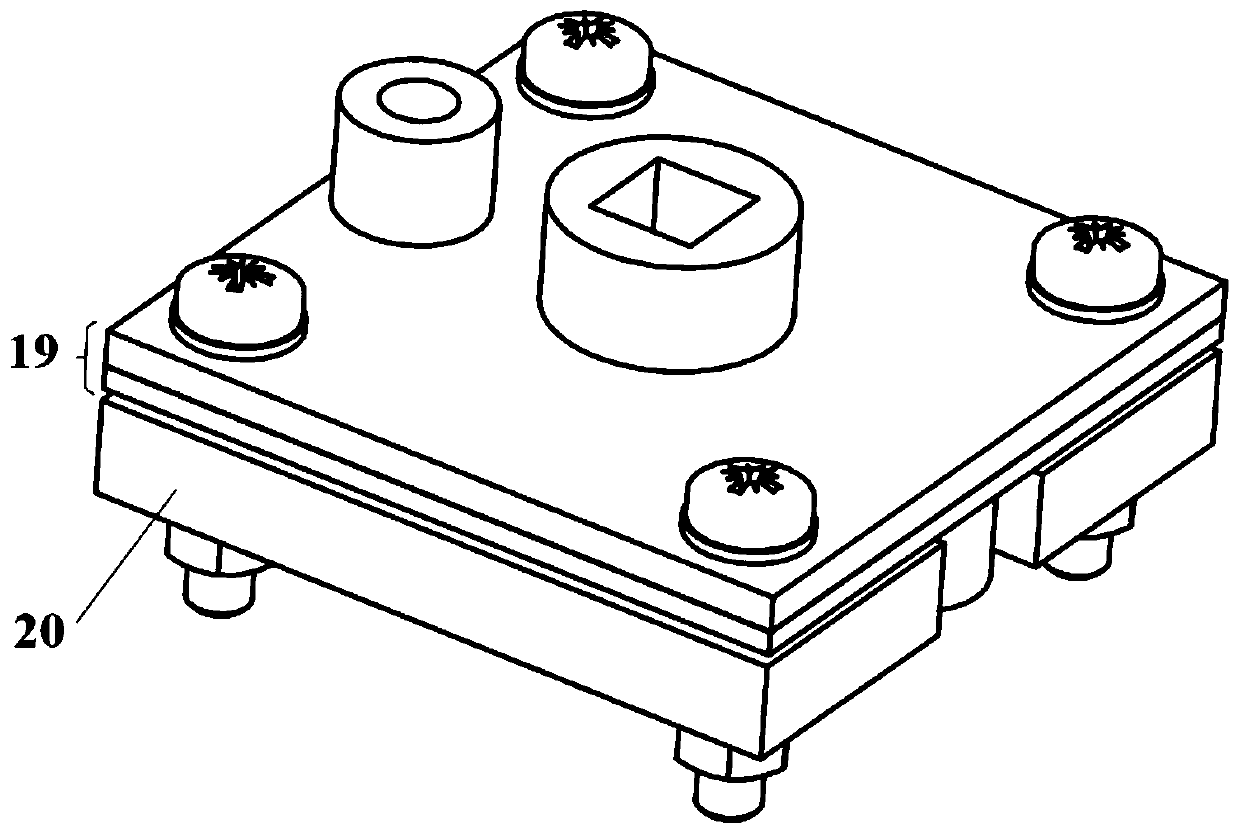

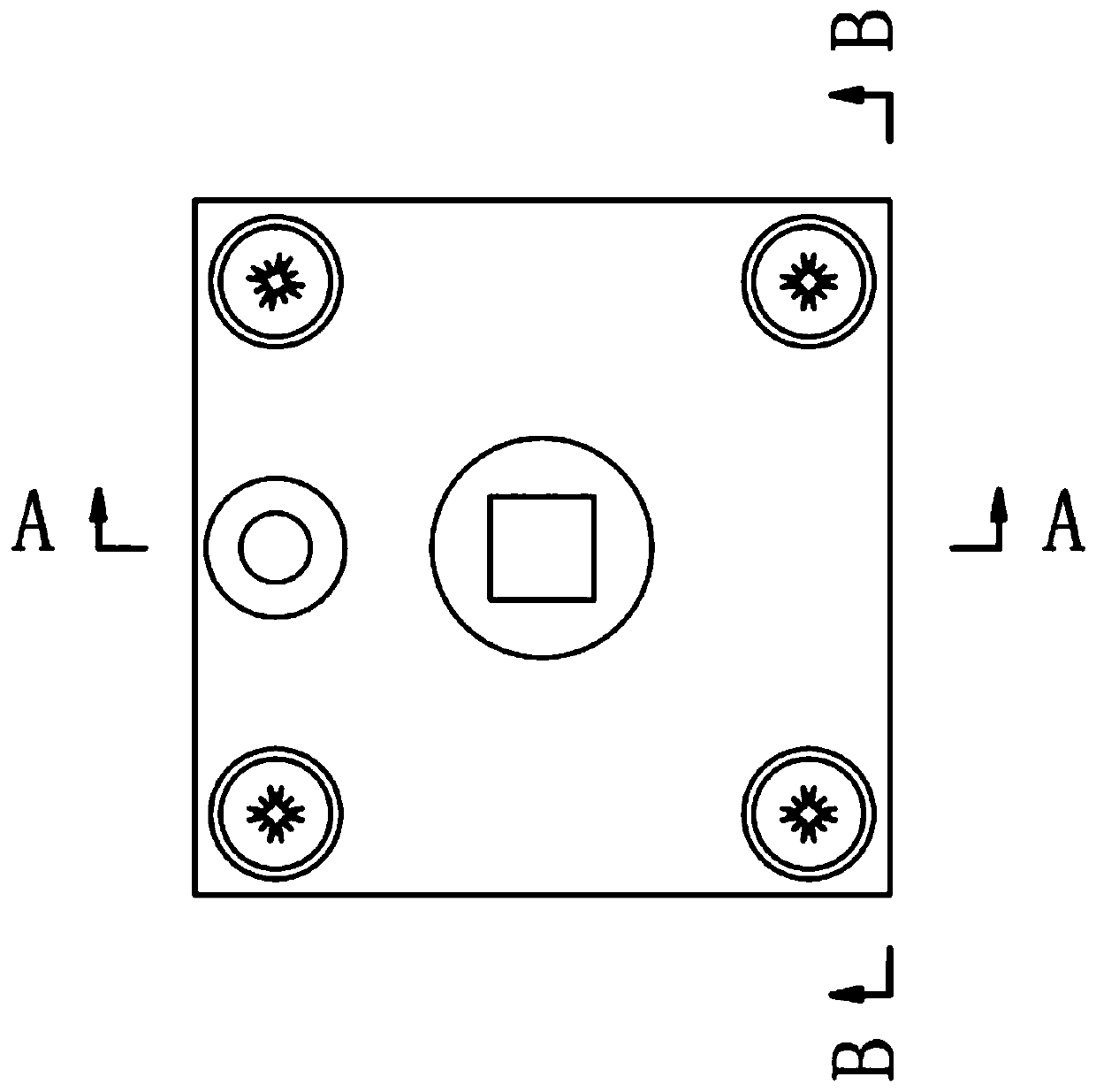

[0038] Further, the thin film evaporation generator 3 includes a bottom plate 20, a cover plate 19, a liquid supply channel 30 is provided in the cover plate 19, and a liquid discharge channel 32 through which excess liquid cooling medium leaves the thin film generator. The cover plate 19 is provided with gas The gas outlet 31 where the cooling medium leaves the thin film generator, the liquid inlet 29 where the liquid cooling medium enters the thin film generator, and the liquid outlet 33 where the excess liquid cooling medium leaves the thin film generator is provided under the cover. The gas outlet 31 on the cover plate 19 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com