Winding needle, wound battery cell and production process of wound battery cell

A winding and needle-rolling technology, which is applied to electrochemical generators, circuits, electrical components, etc., can solve the problems of damaging the alignment of the winding core, wrinkling and deformation of the inner ring of the diaphragm, and taking out the winding core, etc., to achieve rapid discharge Pressing, improving the effect of gap detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

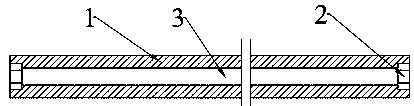

[0049] Such as figure 1As shown, the rolling needle in Example 1 is a solid one-piece cylindrical needle body, and the two ends of the cylindrical needle body 1 are provided with clamping holes 2, the clamping holes 2 are regular hexagonal holes, and the regular hexagonal clamping holes The central axis of 2 coincides with the central axis of needle body 1.

Embodiment 2

[0051] Such as figure 2 As shown, Embodiment 2 is based on Embodiment 1. The difference is that a first through hole 3 is provided between the two clamping holes of the cylindrical needle body, and the openings at both ends of the first through hole 3 communicate with the clamping hole 2 .

Embodiment 3

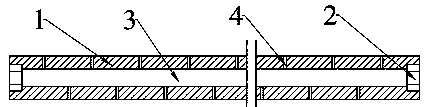

[0053] Such as image 3 As shown, embodiment 3 is based on embodiment 2, the difference is that the columnar needle body is also provided with a second through hole 4, one orifice of the second through hole 4 is located on the circumferential side of the needle body 1, and the other orifice It communicates with the first through hole 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com