Silver nanowire electromagnetic shielding film and preparation method thereof

A technology of electromagnetic shielding film and silver nanowires, which is applied in the fields of magnetic/electric field shielding, shielding materials, cable/conductor manufacturing, etc., can solve problems such as unfavorable electron conduction, achieve damage prevention, excellent electrical conductivity and electromagnetic shielding efficiency, and connect tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

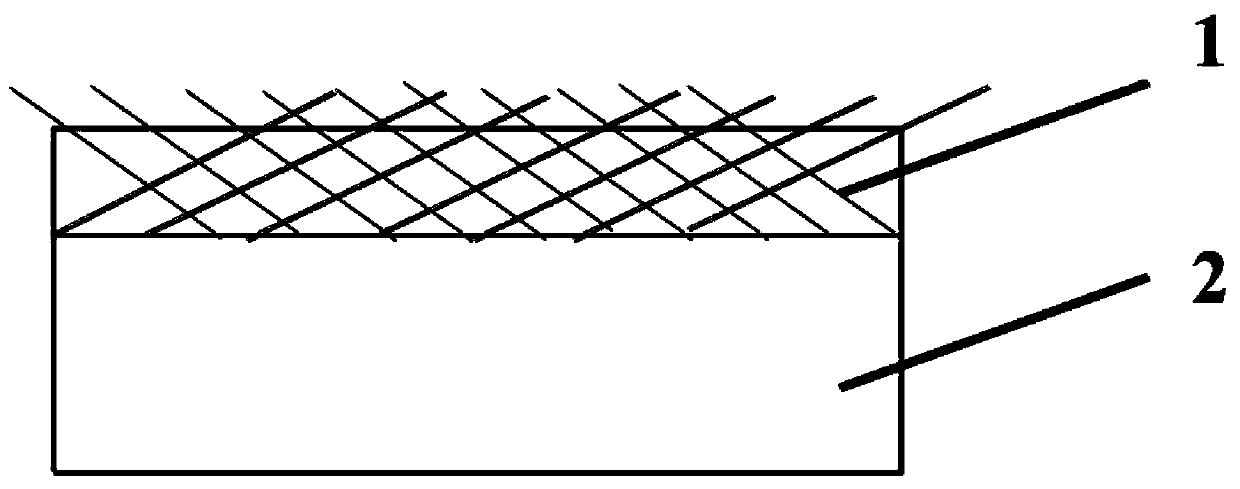

[0028] The invention relates to a preparation method of a silver nanowire electromagnetic shielding film. The silver nanowire electromagnetic shielding film of the invention is composed of a high molecular polymer substrate and a silver nanowire network layer. The polymer polymer base is formed by curing polymer solutions such as polycarbonate, polyurethane, polyacrylic acid and the corresponding curing agent in a certain proportion. Specifically, a low surface energy material such as polytetrafluoroethylene is selected as a mold, and the silver nanowire solution is spin-coated in the mold, and the silver nanowire film is obtained after drying, and the polymer solution and the curing agent are mixed in a certain proportion and then coated. A semi-embedded structure of silver nanowires@polymer substrate is made by covering the surface of the silver nanowire film. The semi-embedded structure of silver nanowires@polymer substrate completely fixes the silver nanowire network in th...

Embodiment 1

[0043] A silver nanowire electromagnetic shielding film and its preparation method:

[0044] Configure the silver nanowire solution: mix silver nanowires with a diameter of 50nm with ethanol to obtain a silver nanowire solution with a solid content of 8%;

[0045] Spin-coat the silver nanowire solution evenly on a polytetrafluoroethylene mold at a speed of 800r / min, and place the coated sample in an oven at 180°C to dry for 15 minutes to obtain a silver nanowire film with a thickness of 5 μm;

[0046] (1) In parts by mass, mix 3 parts of polyurethane solution and 1 part of butyl acetate and shake in an air bath constant temperature oscillator at 25°C (180 times / min) for 1 hour to make them evenly mixed;

[0047] (2) Put the mixed polyurethane polymer solution into a beaker, slowly pump out the air in the cavity with a vacuum pump, and keep the vacuum degree greater than -0.08MPa for 3 minutes. Repeat the above operation 3 times to ensure that the air bubbles in the solution a...

Embodiment 2

[0051] A silver nanowire electromagnetic shielding film and its preparation method:

[0052] First, the silver nanowire solution with a solid content of 8% is evenly spin-coated on a polytetrafluoroethylene mold at a speed of 800r / min, and the coated sample is placed in an oven at 180°C for 15 minutes to obtain silver nanowires. line film;

[0053] (1) According to the number of parts by mass, mix 10 parts of polydimethylsiloxane (PDMS) solution and 1 part of dibutyltin dilaurate and shake in an air bath constant temperature oscillator at 25°C (180 times / min) 1 hour to make it evenly mixed;

[0054] (2) Put the mixed polyurethane polymer solution into a beaker, slowly pump out the air in the cavity with a vacuum pump, and keep the vacuum degree greater than -0.08MPa for 3 minutes. Repeat the above operation 3 times to ensure that the air bubbles in the solution are removed;

[0055] (3) coating the prepared polyurethane solution onto the surface of the silver nanowire film,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com