Rolling bearing inner ring raceway and rolling bearing

A technology for rolling bearings and raceways, applied in the field of rolling bearing inner ring raceways and rolling bearings, can solve problems such as jumping and increasing rolling bearing instability, achieve stability maintenance, improve regional combined bearing capacity, and increase hydrodynamic pressure effects area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

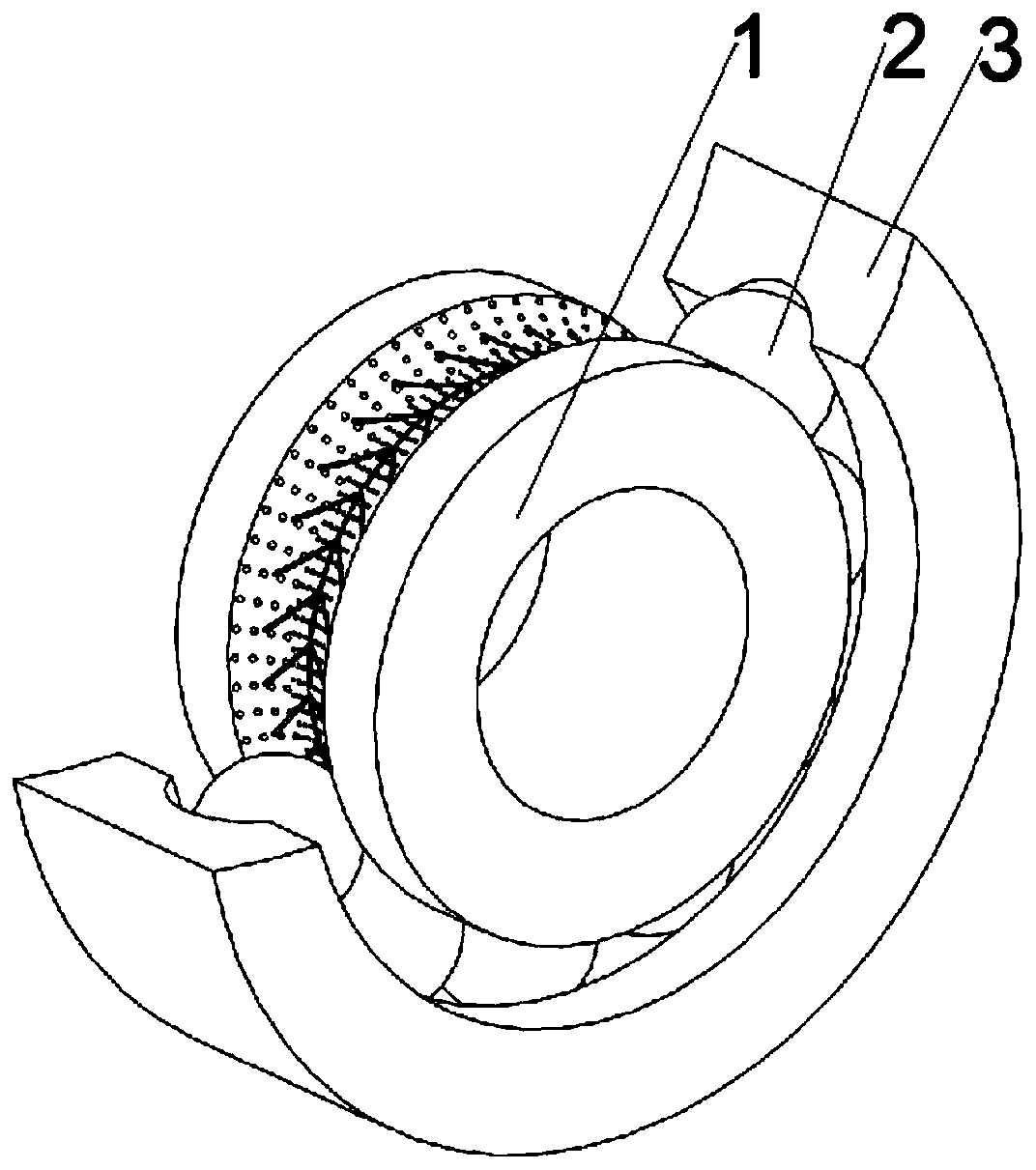

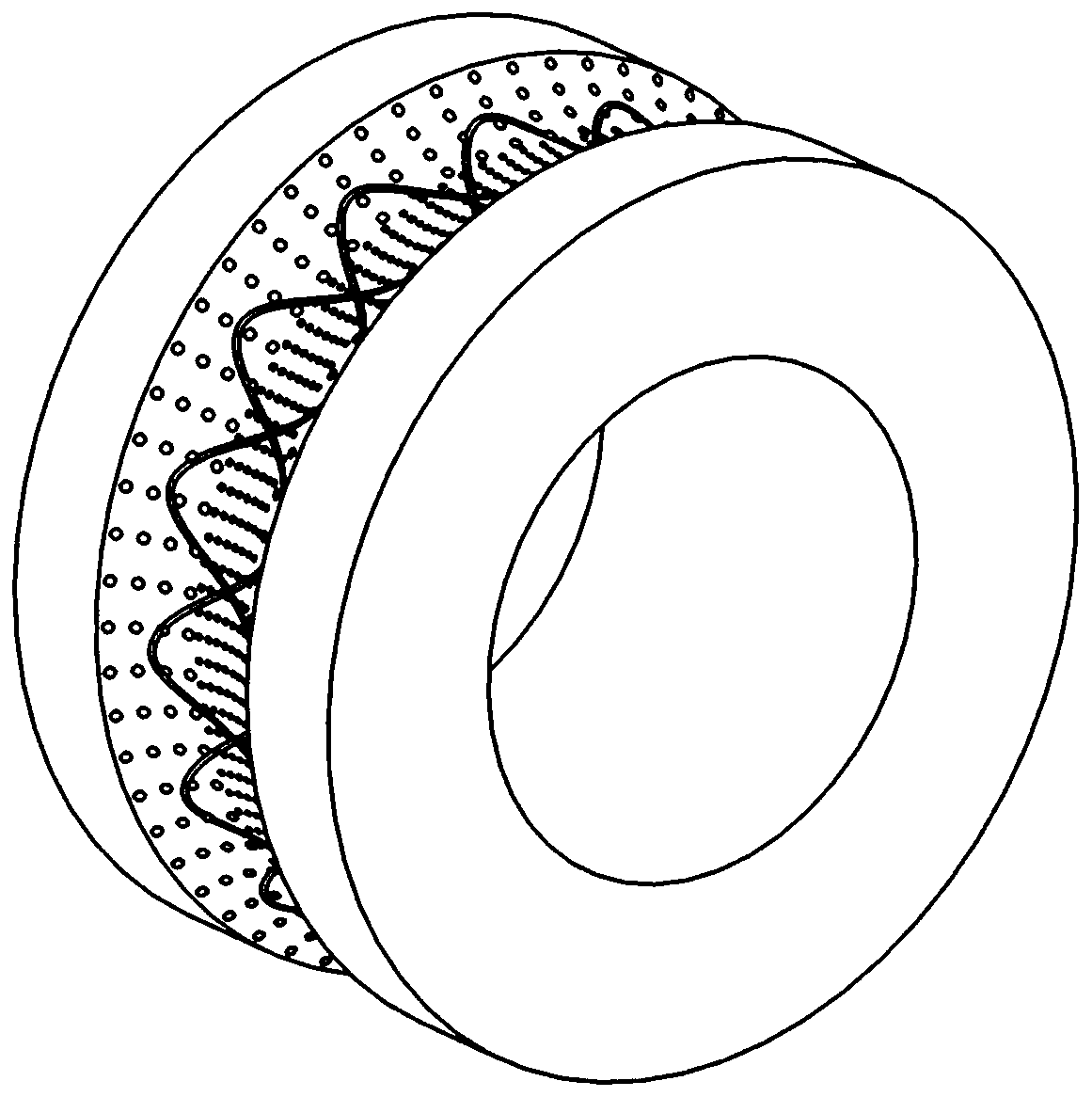

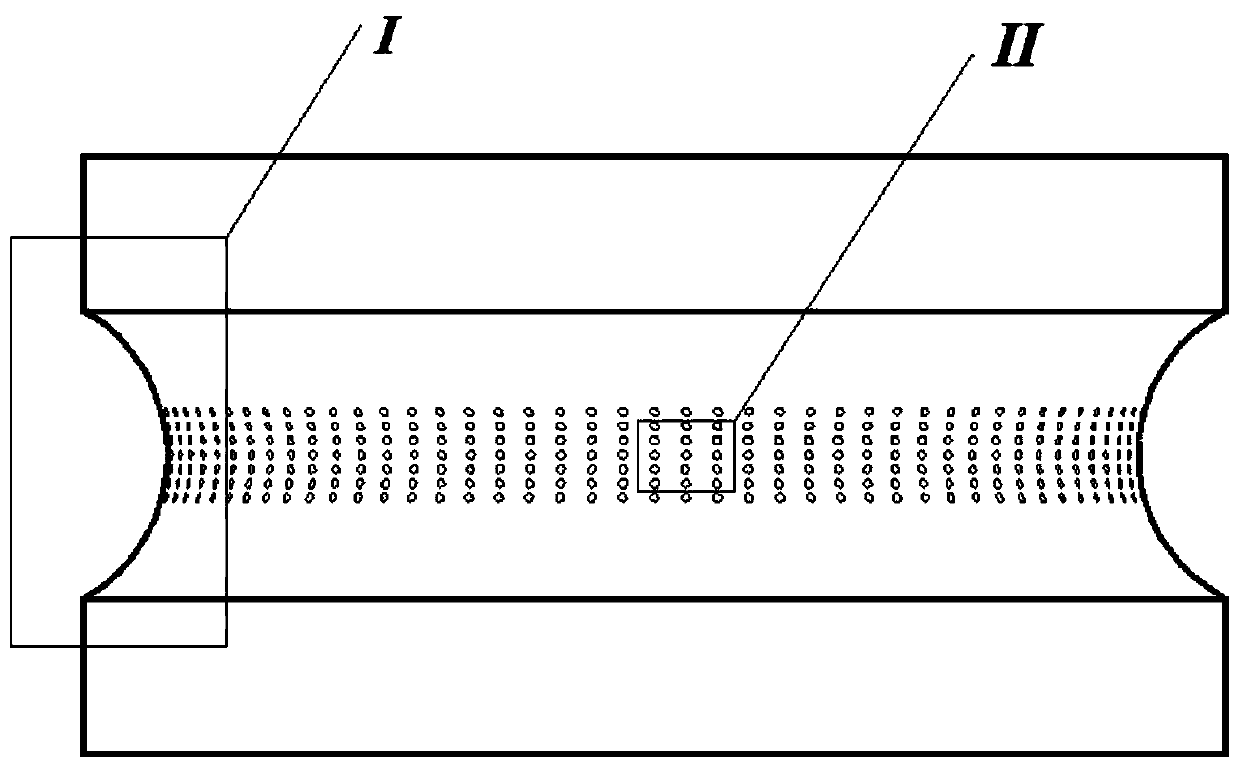

[0035] Such as figure 1 and figure 2As shown, in the raceway of the inner ring of the rolling bearing according to the present invention, a dynamic lubricating texture is provided in the central area of the raceway surface of the inner ring 1 of the rolling bearing, and the dynamic lubricating texture is used to connect the raceway surface and the rolling body 2 The surface is separated to avoid dry friction; the side area of the raceway surface is provided with an oil storage texture, and the side area of the raceway surface is a symmetrical area on both sides of the center area of the raceway surface, which is used for Form a continuous oil film; the surface of the raceway is provided with an oil distribution texture, and the oil distribution texture partially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com