Steel pipe-steel plate combined type corrugated steel web

A steel web and combined technology, applied in the field of steel webs, can solve the problem of increasing the difficulty of welding construction of web extension webs and flange plates, outstanding shear buckling stability of corrugated steel webs, and aesthetic engineering. The influence of material consumption and other issues can improve the efficiency of processing and production, reduce the difficulty of welding construction and cutting, and improve the stability of shear buckling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

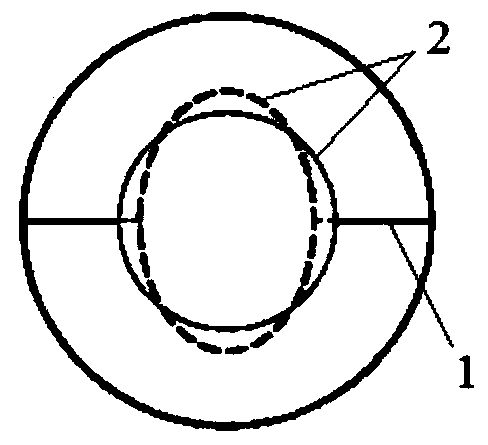

[0057] Such as Figure 1-1i As shown, a steel pipe-steel plate combined steel web according to the present invention includes several steel plates 1 and several steel pipes 2 with circular cross-sections.

[0058] Such as figure 1 with 1a As shown, all the steel pipes 2 are arranged at equal intervals, the axes of all the steel pipes 2 are arranged parallel to each other and are located in the same plane, and the opposite sides of each steel pipe 2 are respectively connected to one of the steel plates 1, the The steel plate 1 is connected to the side wall of the steel pipe 2, all the steel plates 1 are located in the same plane, and the axis of the steel pipe 2 is located in the plane where the steel plate 1 is located; specifically, the steel pipe 2 is a rolled steel pipe or welded Steel pipe, the steel plate 1 and the steel pipe 2 are formed by butt welding in a straight line, and the distance between two adjacent steel pipes 2 can be flexibly adjusted according to the req...

Embodiment 2

[0080] Such as Figure 1j As shown, a steel pipe-steel plate combined steel web according to the present invention differs from Embodiment 1 in that in this embodiment, two adjacent steel pipes 2 are provided with two The steel plate 1, the two steel plates 1 are arranged symmetrically with respect to the plane where the axes of all the steel pipes 2 are located.

Embodiment 3

[0082] Such as Figure 2a-2e As shown, a steel pipe-steel plate combined steel web according to the present invention includes several steel plates 1 and several steel pipes 2 with a square cross-section.

[0083] Such as Figure 2a with 2b As shown, all the steel pipes 2 are arranged at equal intervals, the axes of all the steel pipes 2 are arranged parallel to each other and are located in the same plane, and the opposite sides of each steel pipe 2 are respectively connected to one of the steel plates 1, the The steel plate 1 is connected to the corner edge of the steel pipe 2 and arranged along the diagonal direction of the section of the steel pipe 2, and all the steel plates 1 are located in the same plane; specifically, the steel pipe 2 is a rolled steel pipe or a welded steel pipe , the steel plate 1 and the steel pipe 2 are formed by butt welding in a straight line, and the distance between two adjacent steel pipes 2 can be flexibly adjusted according to the requirem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com