Modacrylic/flame retardant viscose/flame retardant polyester blended flame retardant fabric dyeing technology

A technology of flame-retardant polyester and flame-retardant viscose, which is applied in the field of dyeing technology to achieve the effects of reduced reserves, bright colors, and low processing equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

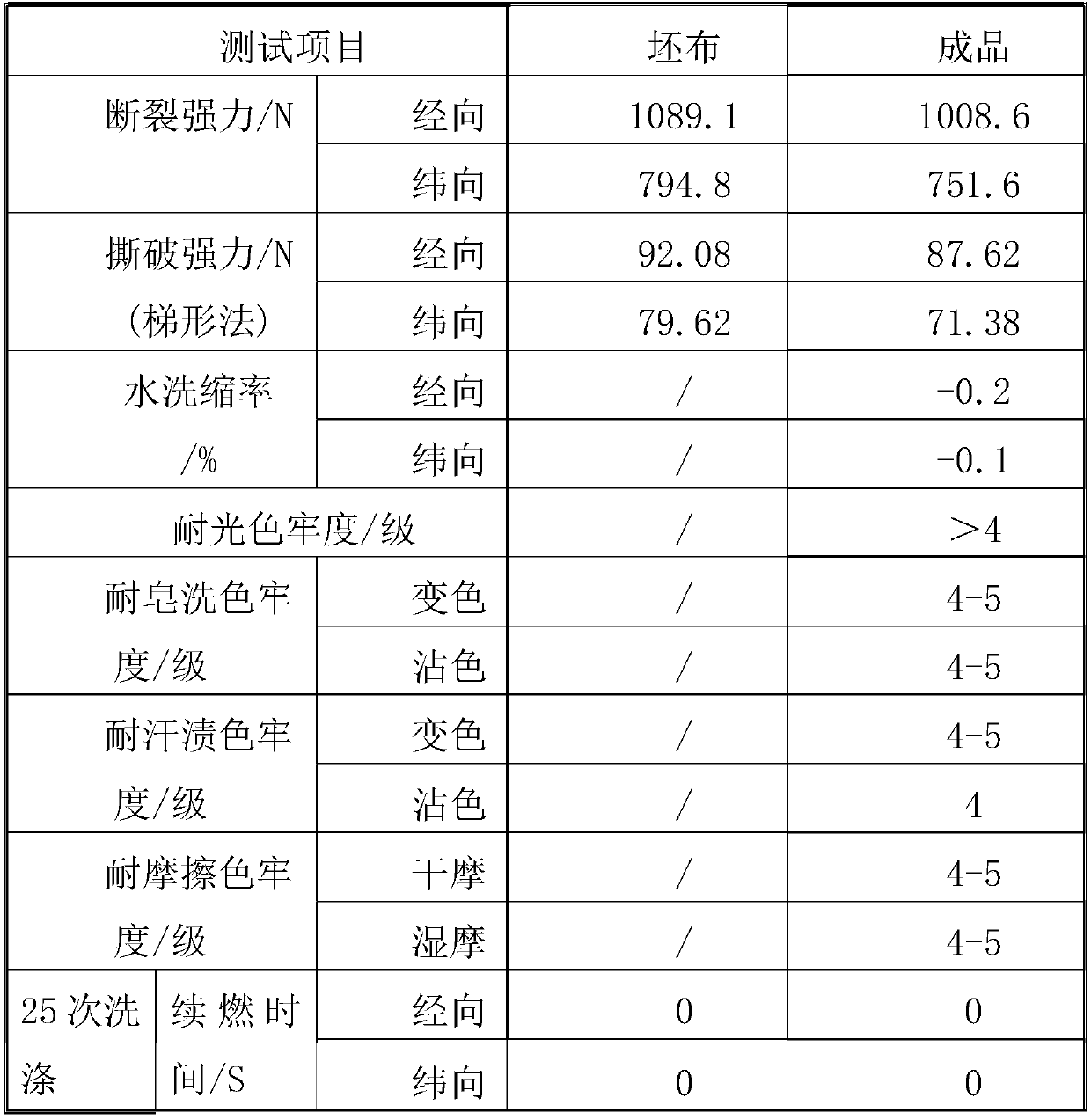

Examples

Embodiment 1

[0036] Use acrylic chloride fiber / flame retardant viscose / flame retardant polyester blended flame retardant fabric, weight 200g / m 2 ;

[0037] Step 1. Desizing and scouring the acrylic / flame retardant viscose / flame retardant polyester blended flame retardant fabric gray fabric with an overflow dyeing machine, the desizing enzyme concentration is 2g / L, and the degreasing agent is 1g / L; The scouring temperature is 80°C and the time is 20 minutes; then wash with cold water and prepare for dyeing;

[0038] Step 2. In the overflow dyeing machine, first use disperse dyes to dye the flame-retardant polyester and acrylic fiber treated in step 1. The dyeing heating process includes: the initial dyeing temperature is 40°C, and the temperature is raised to 1.5°C / min. 100°C, the holding time is 50min; then cool down to 60°C at 2°C / min, and soap with a concentration of 1g / L soaping solution at a temperature of 80°C. Reactive dyes are then used to dye the flame retardant viscose. The hea...

Embodiment 2

[0043] Flame-retardant polyester / acrylic / flame-retardant viscose blended flame-retardant fabric is selected, with a weight of 180g / m 2 ;

[0044] Step 1. Desizing and scouring the acrylic / flame retardant viscose / flame retardant polyester blended flame retardant fabric gray fabric with an overflow dyeing machine, the concentration of desizing enzyme is 5g / L, and the degreasing agent is 2g / L; The scouring temperature is 90°C and the time is 20 minutes; then wash with cold water and prepare for dyeing;

[0045] Step 2. In the overflow dyeing machine, first use disperse dyes to dye the flame-retardant polyester and acrylic fiber treated in step 1. The dyeing heating process includes: the initial dyeing temperature is 40°C, and the temperature is raised to 1°C / min. 95°C, the holding time is 45min; then cool down to 60°C at 2°C / min, and soap with a concentration of 1g / L soaping solution at a temperature of 80°C. Reactive dyes are then used to dye the flame retardant viscose. The ...

Embodiment 3

[0050] Use acrylic chloride fiber / flame retardant viscose / flame retardant polyester blended flame retardant fabric, weight 200g / m 2 ;

[0051] Step 1. Desizing and scouring the acrylic / flame retardant viscose / flame retardant polyester blended flame retardant fabric gray fabric with an overflow dyeing machine, the desizing enzyme concentration is 2g / L, and the degreasing agent is 1g / L; The scouring temperature is 80°C and the time is 10 minutes; then wash with cold water and prepare for dyeing;

[0052] Step 2. In the overflow dyeing machine, first use disperse dyes to dye the flame-retardant polyester and acrylic chloride fiber treated in step 1. The dyeing heating process includes: the initial dyeing temperature is 45°C, and the temperature is raised to 2°C / min. 105°C, the holding time is 60min; then cool down to 60°C at 2°C / min, and soap with a concentration of 2g / L soaping solution at a temperature of 90°C. Reactive dyes are then used to dye the flame retardant viscose. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com