Preparation method of photoluminescence fiber by centrifugal spinning

A technology of centrifugal spinning and photoluminescence, which is applied in the field of fiber materials to achieve the effects of reducing quantum dot aggregation, stable and reliable optical performance, and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

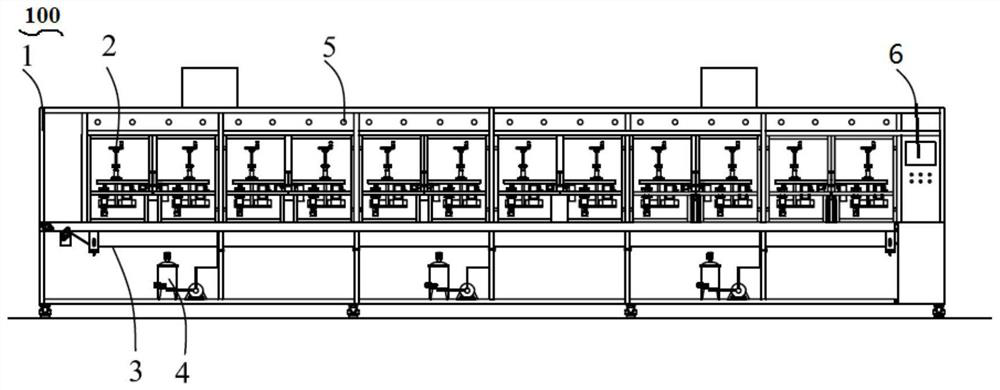

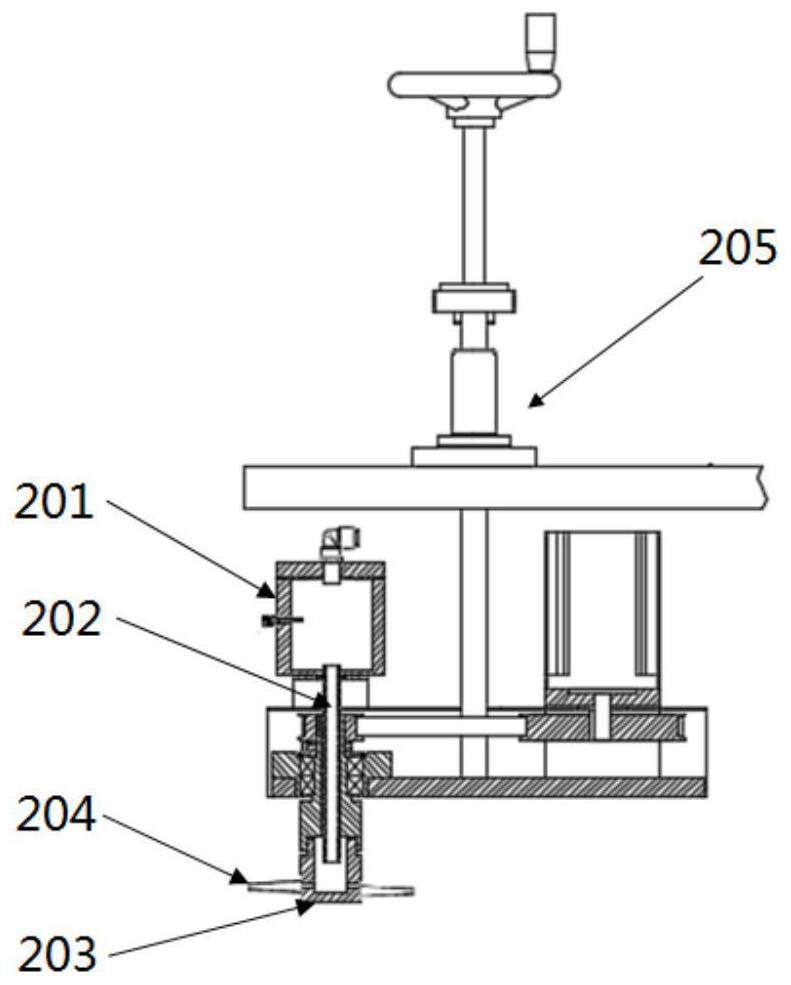

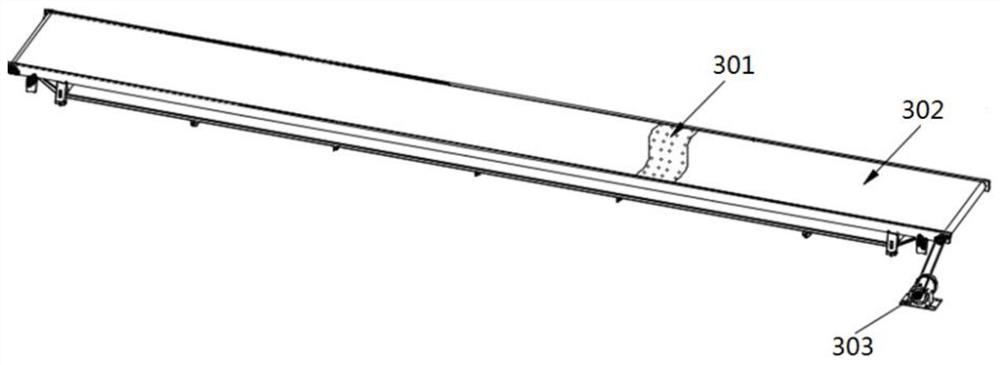

[0057] A kind of centrifugal spinning preparation method of photoluminescence fiber, by Figure 1-3 The shown planar receiving centrifugal spinning device 100 is implemented, comprising the following steps:

[0058] S1, preparing quantum dots;

[0059] S2. Preparation of spinning solution: blending quantum dots and high molecular polymers in a solvent, and stirring to obtain a predetermined mass fraction of quantum dots / high molecular polymer spinning solutions;

[0060] S3. Preparing photoluminescent fibers by centrifugal spinning: inject the spinning solution described in step S2 into a plane-receiving centrifugal spinning device, and perform centrifugal spinning to obtain photoluminescent fibers.

[0061] Preferably, during the centrifugal spinning process, the diameter of the spinneret of the spinneret is 0.1-1 mm; the spinning distance between the spinneret and the collecting device is 0-12 cm.

[0062] Preferably, during the centrifugal spinning process, the spinning t...

Embodiment 1

[0067] The centrifugal spinning preparation method of silicon quantum dot / polyurethane photoluminescence fiber comprises the steps:

[0068] S1. Preparation of oil-dispersed silicon quantum dots:

[0069] S11. Take 0.6g of silicon powder and pour it into a container, add 20mL of absolute ethanol and 40mL of a 48% hydrofluoric acid solution and stir at room temperature with a rotation speed of 600r / min for 4.5h;

[0070] S12. Extract with an appropriate amount of n-pentane, quickly separate the dark brown solution in the upper layer into the reactor, add 20 mL of decene into the reactor, and then vacuum dry it;

[0071] S13. Put the reactor into an oven, and the reaction condition is to raise the room temperature to 170° C. in 1 hour, keep at this temperature for 6 hours, and then lower the temperature to room temperature in 6 hours;

[0072] S14. After the reaction is finished, transfer the reaction kettle solution to a centrifuge tube, add petroleum ether (boiling range of 6...

Embodiment 2-10

[0081] The difference from Example 1 is that the mass fractions of oil-dispersible silicon quantum dots and polyacrylonitrile are different, as shown in Table 1, and other steps are the same as in Example 1, and will not be repeated here.

[0082] Table 1 is the setting of the mass fraction of oil-dispersible silicon quantum dots and polyacrylonitrile in Examples 1-10

[0083]

[0084]

[0085] In the centrifugal spinning process, the factors affecting fiber diameter and performance can be divided into two aspects: internal and external. The internal factor is the concentration of the spinning solution. The concentration of the spinning solution directly affects the viscosity of the spinning solution. If the viscosity is too low, the surface tension will be too high; if the viscosity is too high, the molecular chains of polyacrylonitrile polymers will be entangled, and continuous and uniform fibers cannot be formed. Within a certain range, as the concentration of the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com