Glass product internal film plating machine

A glass product and coating machine technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., to achieve good coating effect, ensure continuity, and facilitate disassembly and installation of metal wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

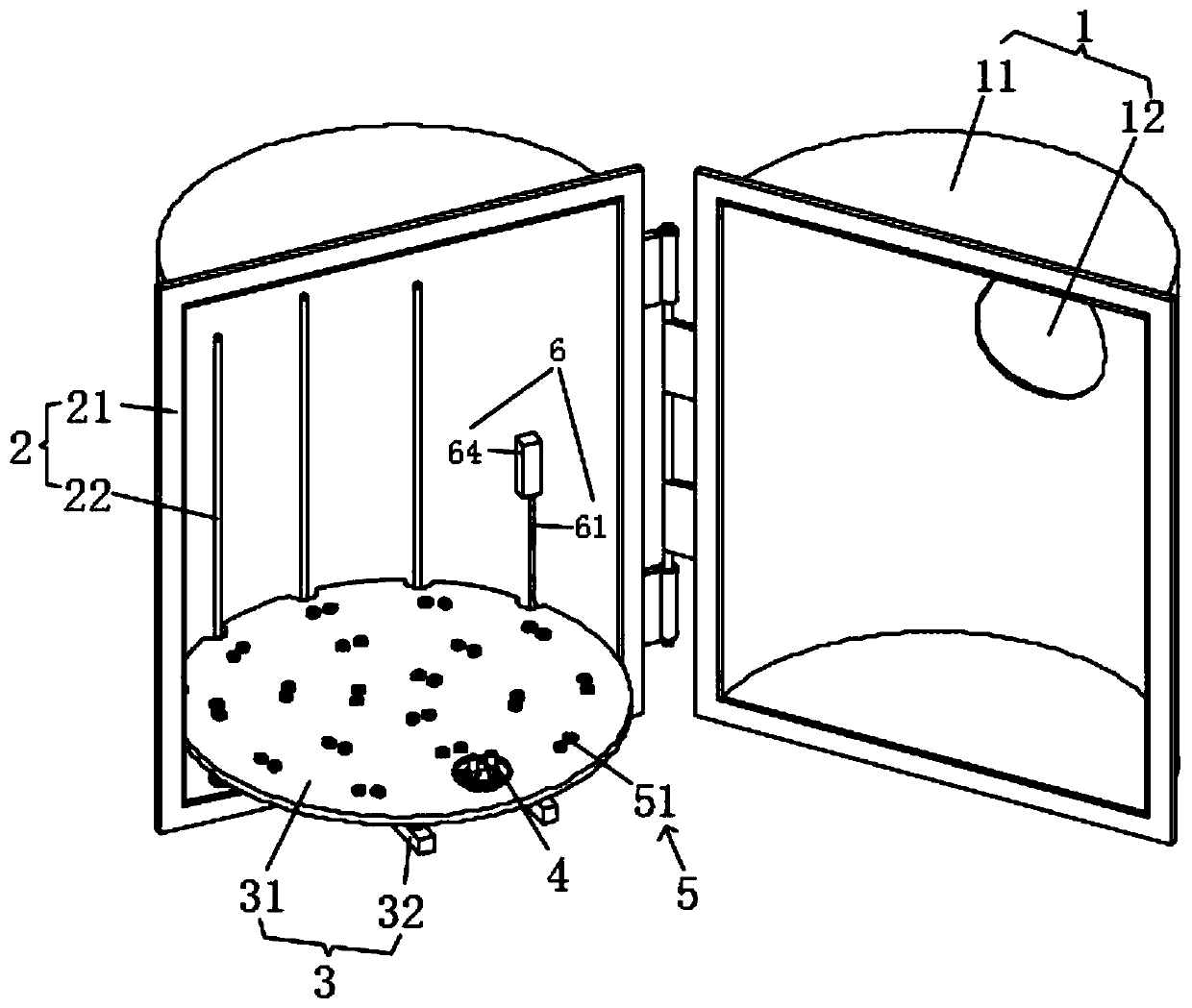

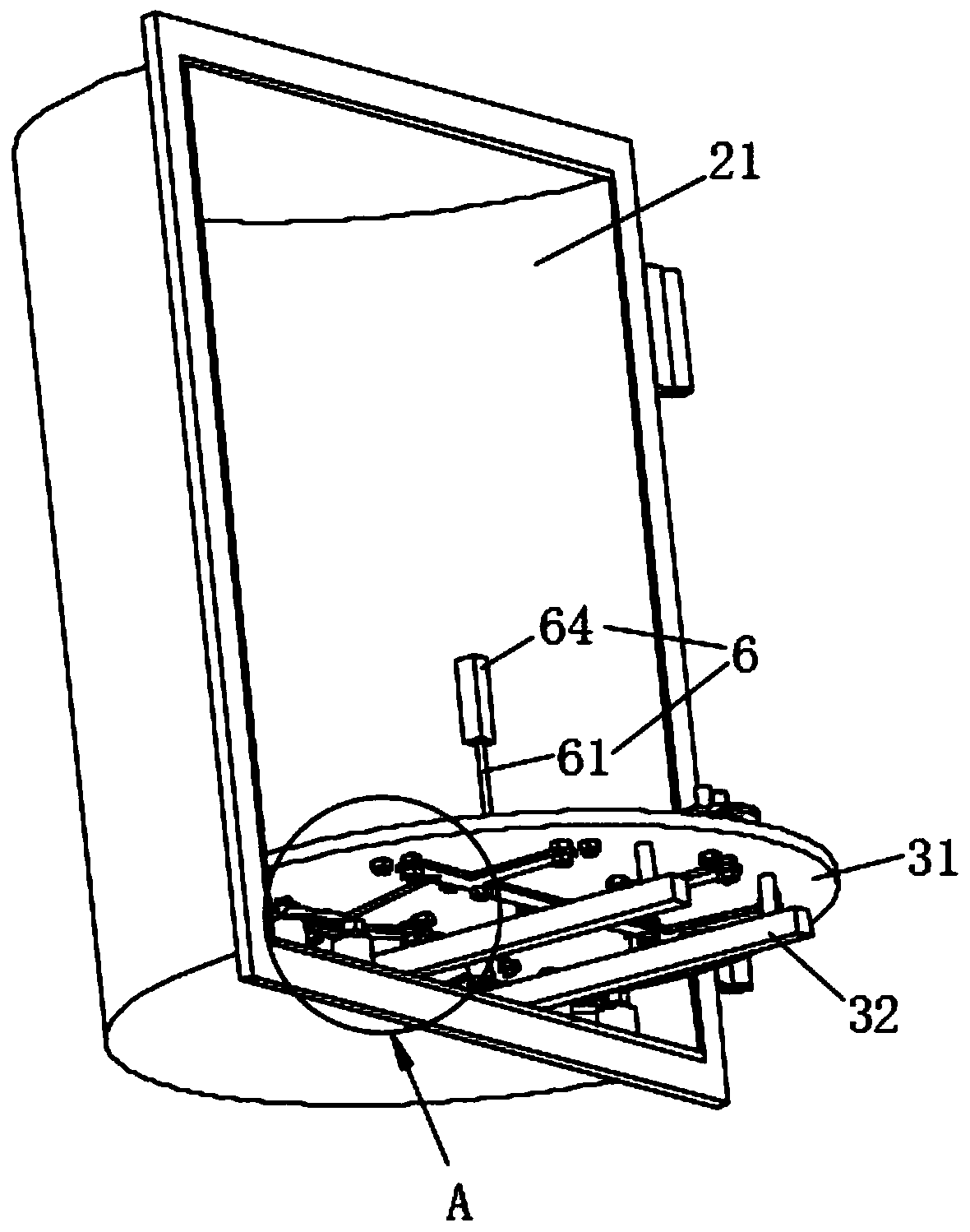

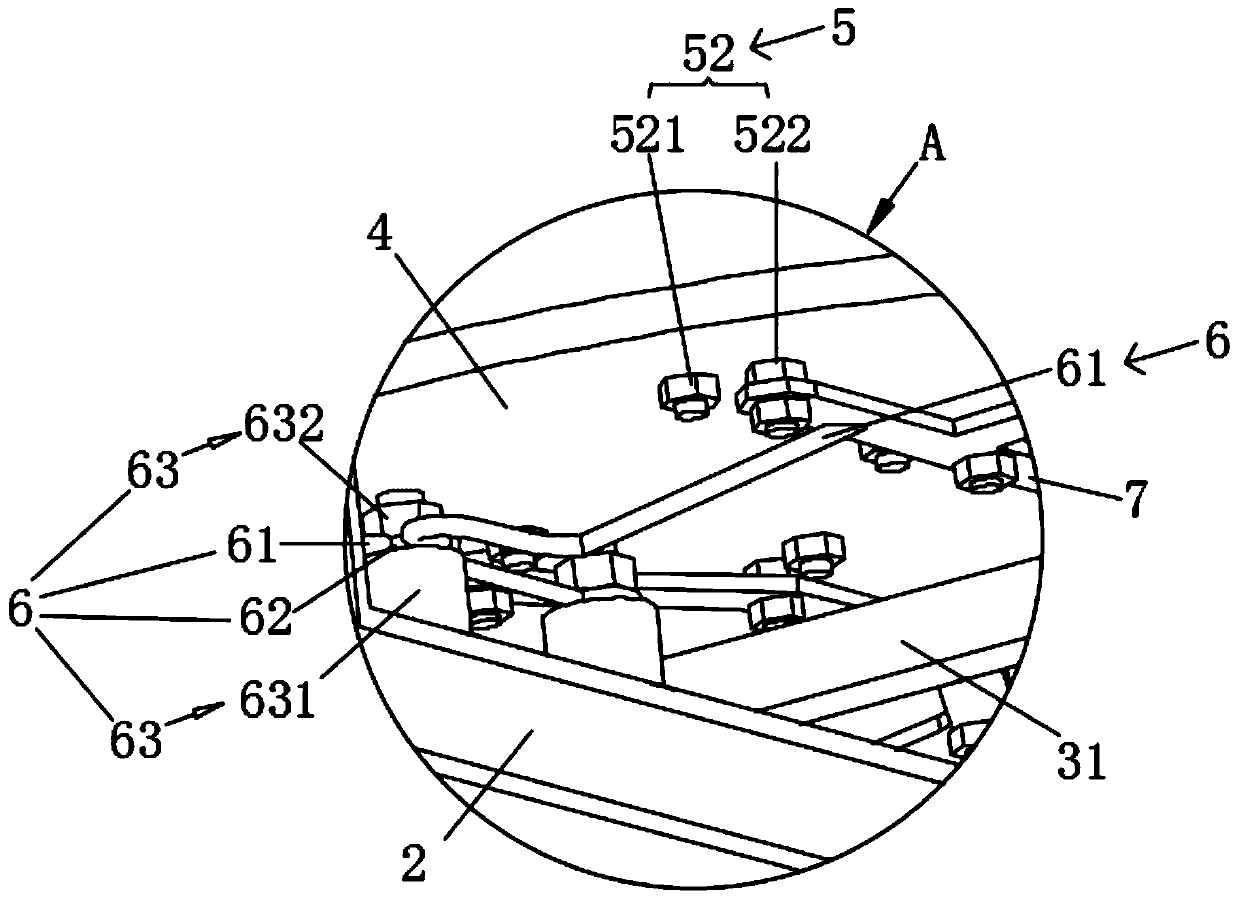

[0036] See figure 1 This embodiment discloses an internal coating machine for glass products, which includes a vacuum shell 1, an internal coating shell 2, a support plate 3, a coating component 4, a positive and negative electrode conductive component 5, a energized component 6, a conductive sheet 7, a metal Silk 8. The vacuum housing 1 and the inner coating housing 2 are connected in rotation. The support plate 3 is fixed inside the inner coating shell 2. A plurality of positive and negative conductive components 5 are uniformly distributed on the support plate 3. Each positive and negative electrode conductive component 5 is provided with a coating component 4. The coating assembly 4 is provided with a metal wire 8 for coating by energizing evaporation. The negative electrodes of the plurality of positive and negative electrode conductive components 5 are connected by a conductive sheet 7. The conductive sheet 7 is electrically connected to an external power source throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com