Method for extracting taraxacum rubber

A technology of dandelion rubber and extraction method, which is applied in the field of extraction of dandelion rubber, and can solve the problem of toxic cost of solvent method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

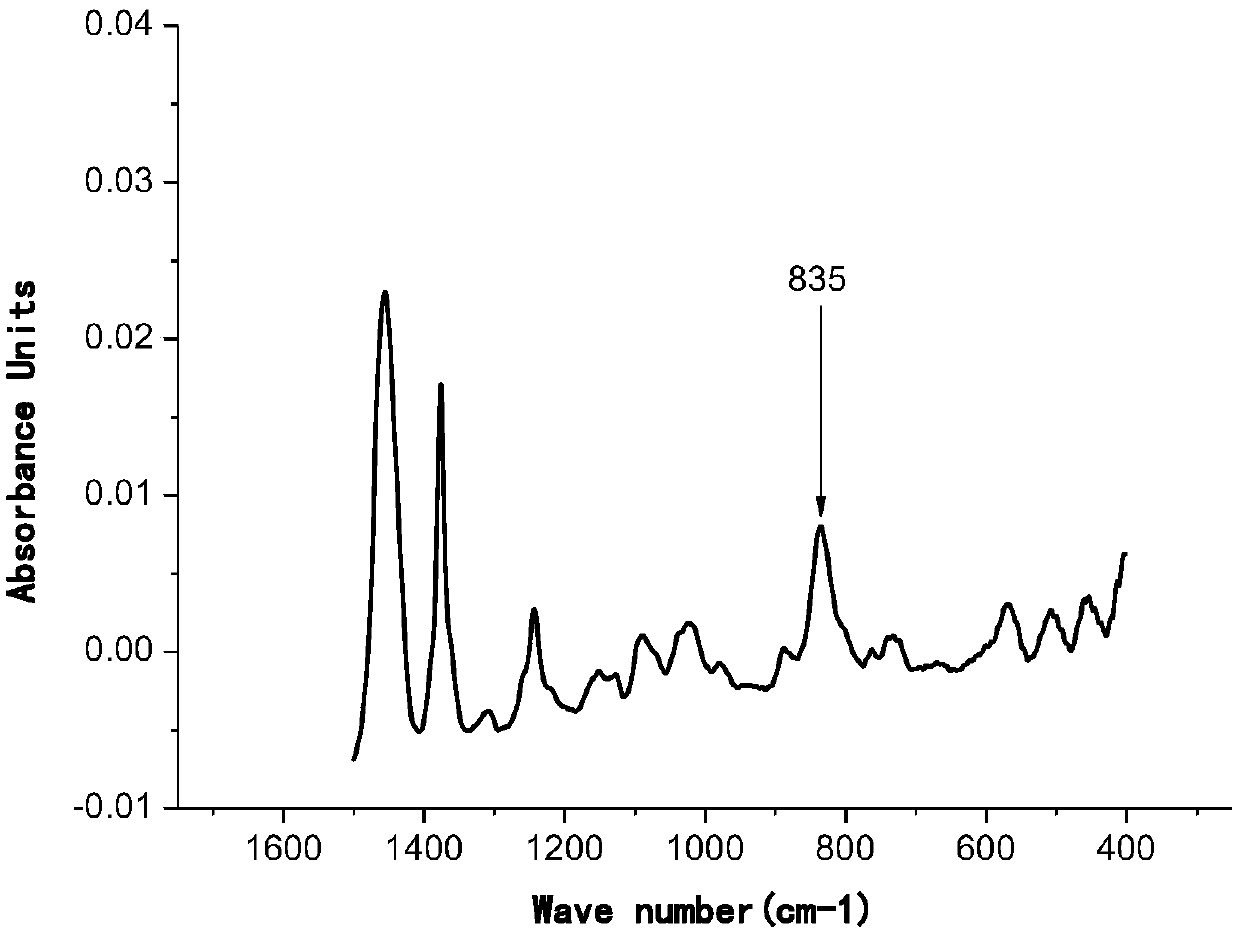

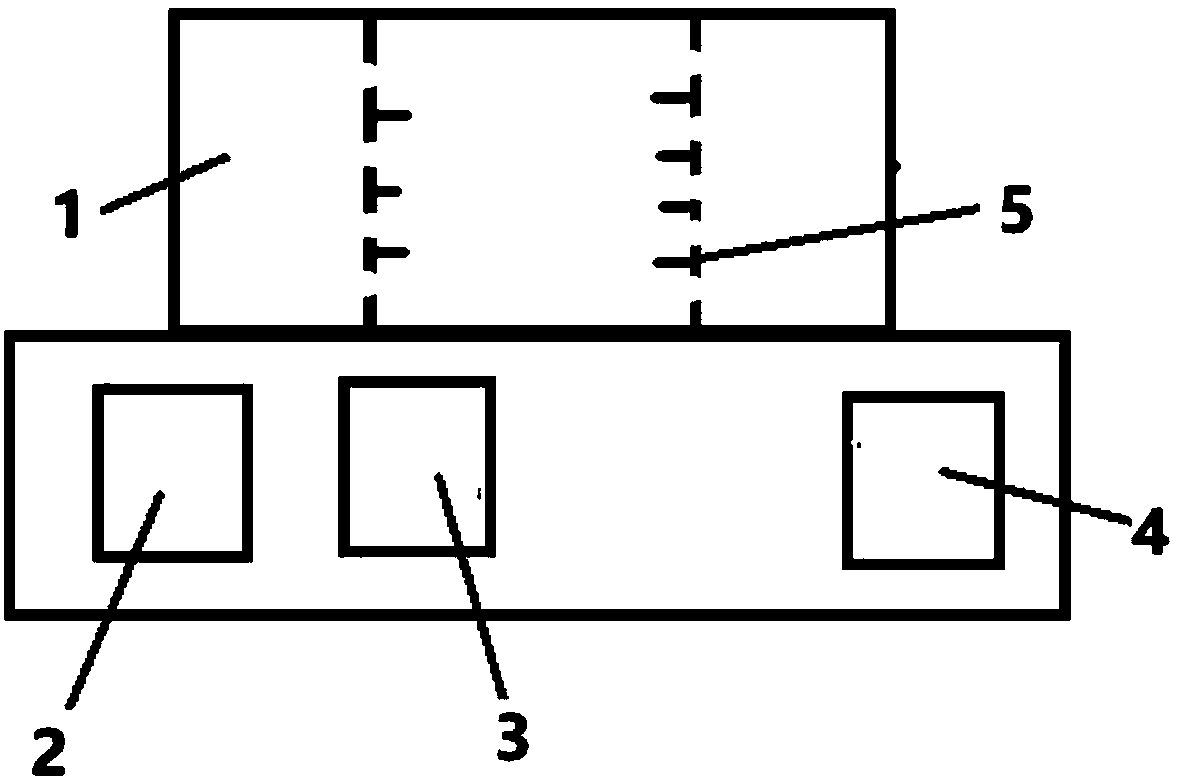

Image

Examples

Embodiment 1

[0082] Acid-base neutralization and gel extraction method:

[0083] (1) Boil the dried root of dandelion rubber grass in water for one hour, peel the skin and pull out the core, and separate the root pulp from the root bark;

[0084] (2) 100g root pulp is boiled in 500ml of sulfuric acid solution at a concentration of 3% for 4h, then filtered, the filter residue is separated from the filtrate, the filter residue is dried to obtain rubber, and the filtrate is reserved for subsequent use;

[0085] (3) Boil 160g of root bark in 600ml of water for one hour, then dump the waste liquid; boil 80g of root bark in 570ml of 3% KOH solution for 4h, then filter, separate the filter residue from the filtrate, and dry the filter residue Rubber can be obtained, and the filtrate is reserved for subsequent use;

[0086] (4) Neutralize the filtrate in the process of acid boiling and alkali boiling. Through equivalent calculation, the filtrate of the acid boiling and alkali boiling parts obtain...

Embodiment 2

[0091] (1) Boil the dried root of dandelion rubber grass in water for one hour, peel the skin and pull out the core, and separate the root pulp from the root bark;

[0092] (2) 200g root pulp is boiled in 500ml of sulfuric acid solution at a concentration of 1% for 1h, then filtered, the filter residue is separated from the filtrate, the filter residue is dried to obtain rubber, and the filtrate is retained for subsequent use;

[0093] (3) Boil 320g root bark in 600ml water for one hour, then dump waste liquid; boil 80g root bark in 570ml 1% KOH solution for 1h, then filter, separate the filter residue from the filtrate, and dry the filter residue Rubber can be obtained, and the filtrate is reserved for subsequent use;

[0094] (4) Neutralize the filtrate in the process of acid boiling and alkali boiling. Through equivalent calculation, the filtrate of the acid boiling and alkali boiling parts obtained according to the above feeding ratio can be just neutralized to neutral, an...

Embodiment 3

[0097] (1) Boil the dried root of dandelion rubber grass in water for one hour, peel the skin and pull out the core, and separate the root pulp from the root bark;

[0098] (2) 80g root pulp is boiled 4h in the sulfuric acid solution under the 7% concentration of 500ml, then filters, and filter residue is separated from filtrate, and filter residue can be dried to obtain rubber, and filtrate is reserved for subsequent use;

[0099] (3) Boil 90g of root bark in 600ml of water for one hour, then dump the waste liquid; boil 80g of root bark in 570ml of 7% KOH solution for 4h, then filter, separate the filter residue from the filtrate, and dry the filter residue Rubber can be obtained, and the filtrate is reserved for subsequent use;

[0100] (4) Neutralize the filtrate in the process of acid boiling and alkali boiling. Through equivalent calculation, the filtrate of the acid boiling and alkali boiling parts obtained according to the above feeding ratio can be just neutralized to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com