Construction method for erecting electrified railway uplink and downlink crossover contact net

A technology for electrified railways and construction methods, applied in overhead lines and other directions, can solve problems such as large measurement errors of workers, deviation of insulator positions, and long time for overhead lines to occupy skylights.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

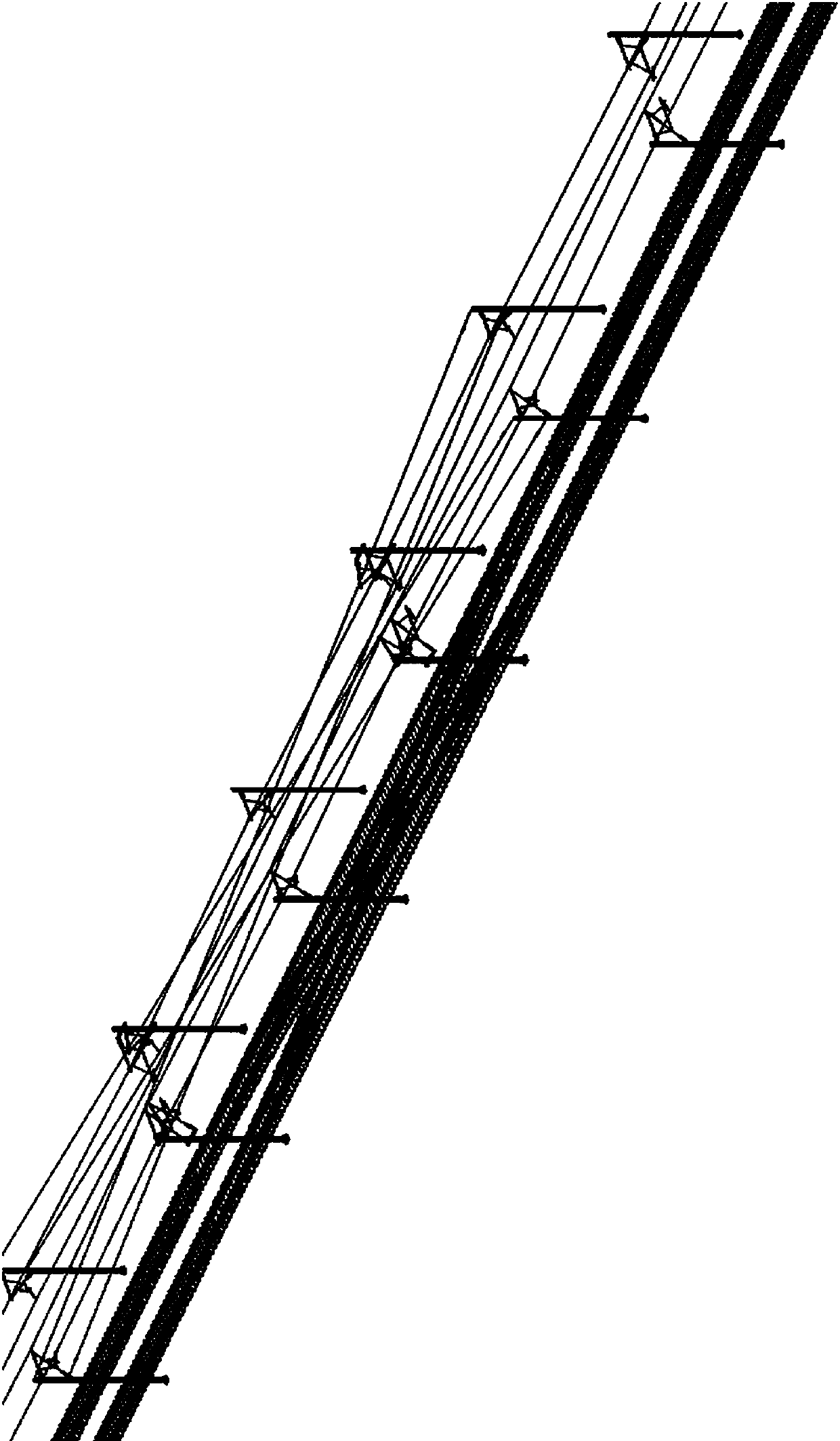

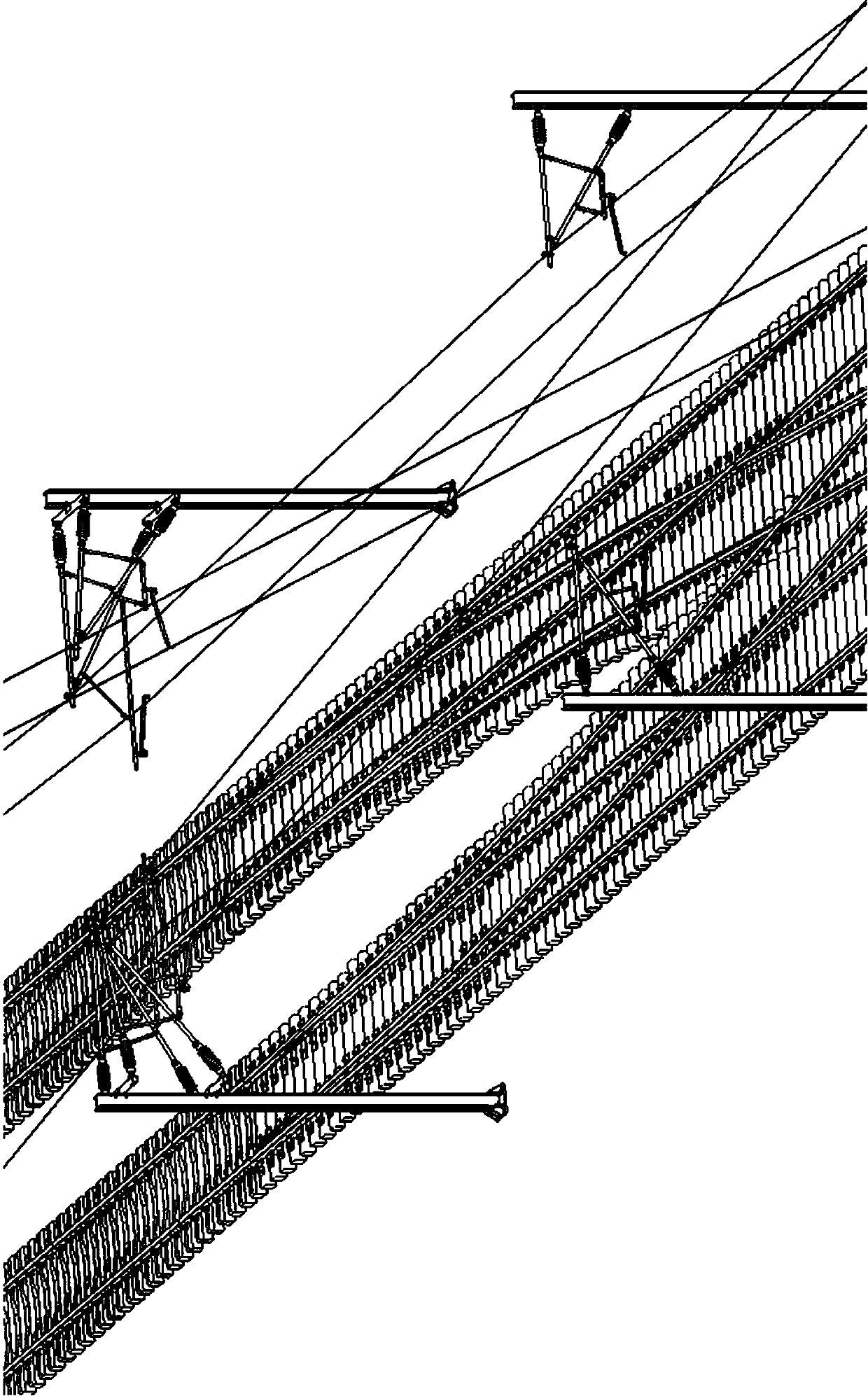

[0033] The present invention will be described in detail below by taking 8 stations of a certain line as an example. The line has 2 to 4 suspended skylights per month, and the power outage time is 55 minutes. The effective working time after the power outage is about 35 minutes. Affected by transportation, construction Skylights are often removed. The 8-station net-hanging project of the line involves 8 stations in total, and a total of 12 catenary lines for uplink and downlink crossing lines need to be erected. The floor plan of catenary in the throat area of one of the stations is as follows image 3 As shown, the lengths of the two anchor sections D11 and D12 are both 400 meters, the 31# and 32# pillars are anchored with full compensation, the 45# and 46# pillars are anchored without compensation, and 9 / 11 / 13 / 15 is 12 No. crossover line, the D11 anchor section is anchored from the 31# pillar, passing through the No. 9 and 11 turnouts to the 46# pillar and anchored, D12 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com