Automatic machining machine tool transmission mechanism of metal plate shell

A technology for processing machine tools and transmission mechanisms, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of conveyor belt shaking, damage to elastic plates and movable pressure bars, and reduce the service life of conveyor belts. The method is simple, the effect of avoiding position deviation and reducing the error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

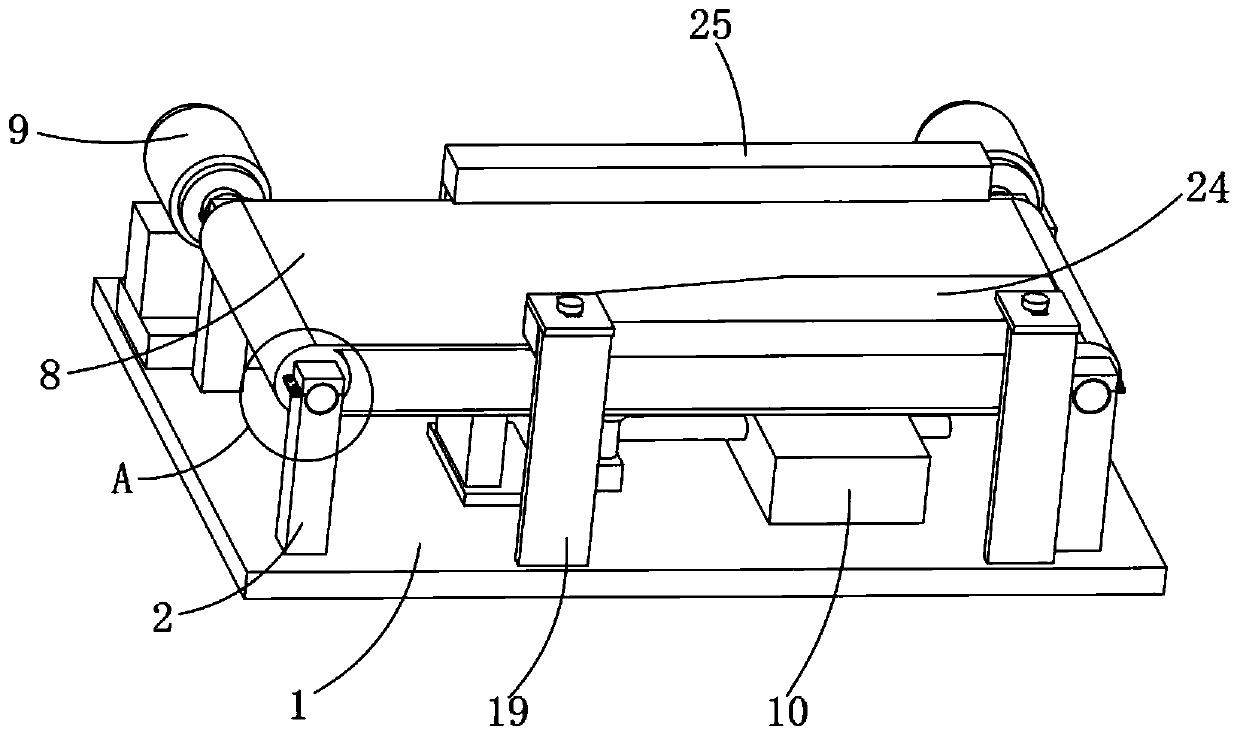

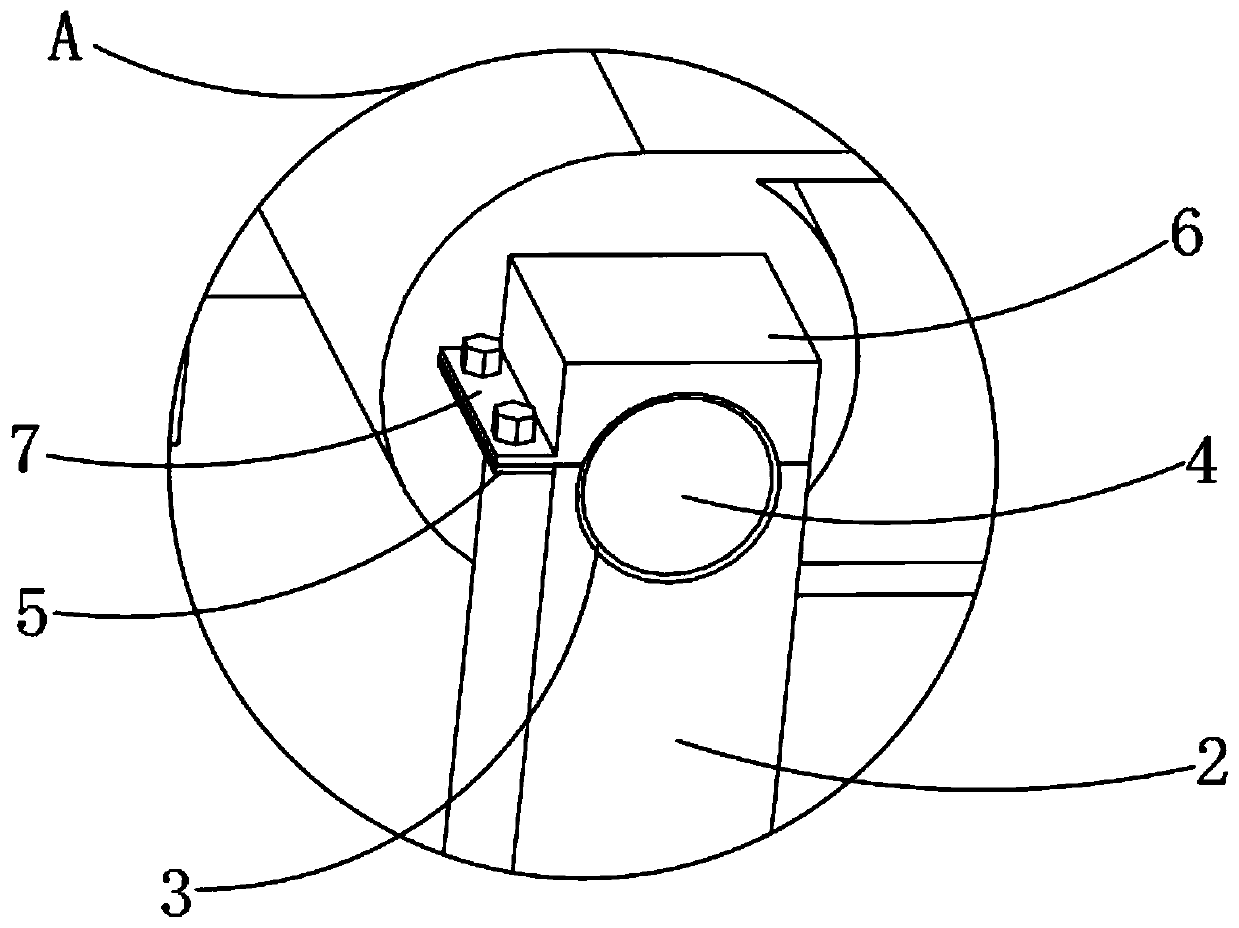

[0025] Example: such as Figure 1-4 As shown, the present invention provides a technical solution, an automatic processing machine tool transmission mechanism for a sheet metal shell, a first support frame 2 is symmetrically installed at the four corners of the top of the base 1, and the top of the first support frame 2 One end is connected with a bump 5, and the top of the first support frame 2 is provided with a groove 3, and a roller 4 is installed inside the groove 3, the number of the roller 4 is two, and one end of the roller 4 is installed in the groove 3, the other end of the roller 4 extends into the corresponding other groove 3 and is connected with the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com