A kind of copolymerization modified layered graphite phase carbon nitride photocatalyst and its preparation method and application

A technology of phase carbon nitride light and layered graphite, which is applied in the field of preparation of semiconductor nanomaterials and photocatalysis, can solve the problems of few photocatalysts and the like, and achieve the effects of improved hydrogen production effect, simple preparation method and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

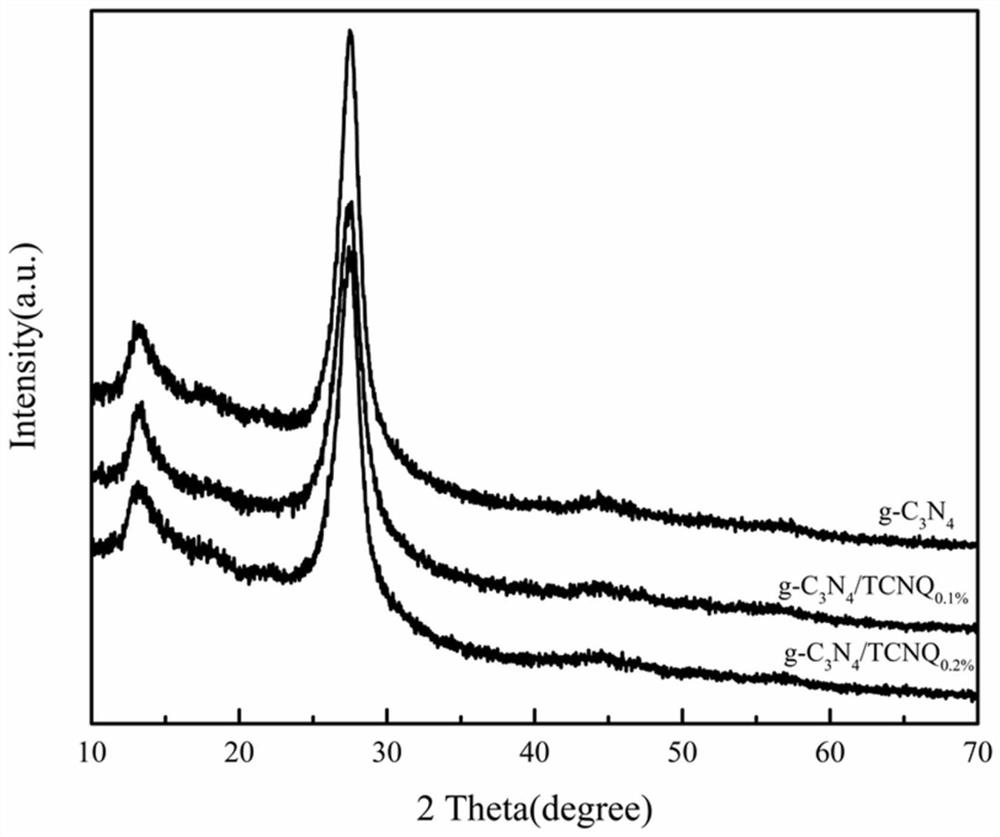

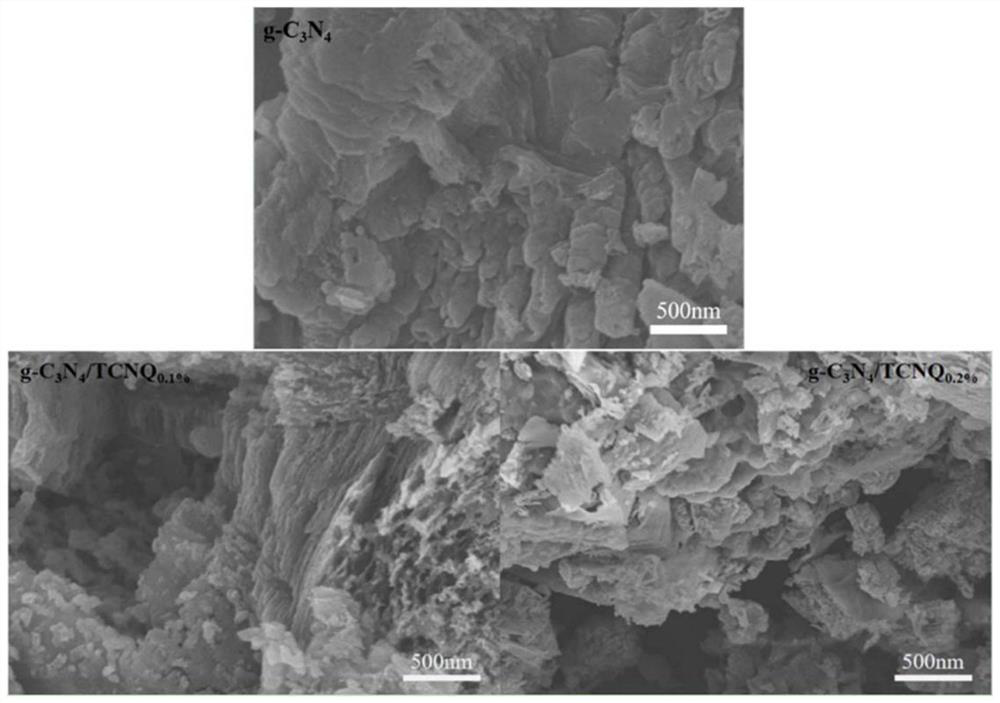

[0023] (1) Add 5 g of melamine and 5 mg of TCNQ into a ceramic mortar and grind continuously to obtain a mixed solid powder;

[0024] (2) Spread the mixed solid powder prepared in step (1) evenly in a quartz boat, place it in a tube furnace, raise the temperature to 520°C at a heating rate of 5°C / min in an air atmosphere, keep it for 4 hours and then follow the furnace Cool down to room temperature, make the layered graphitic phase carbon nitride photocatalyst (g-C 3 N 4 / TCNQ 0.1% ).

Embodiment 2

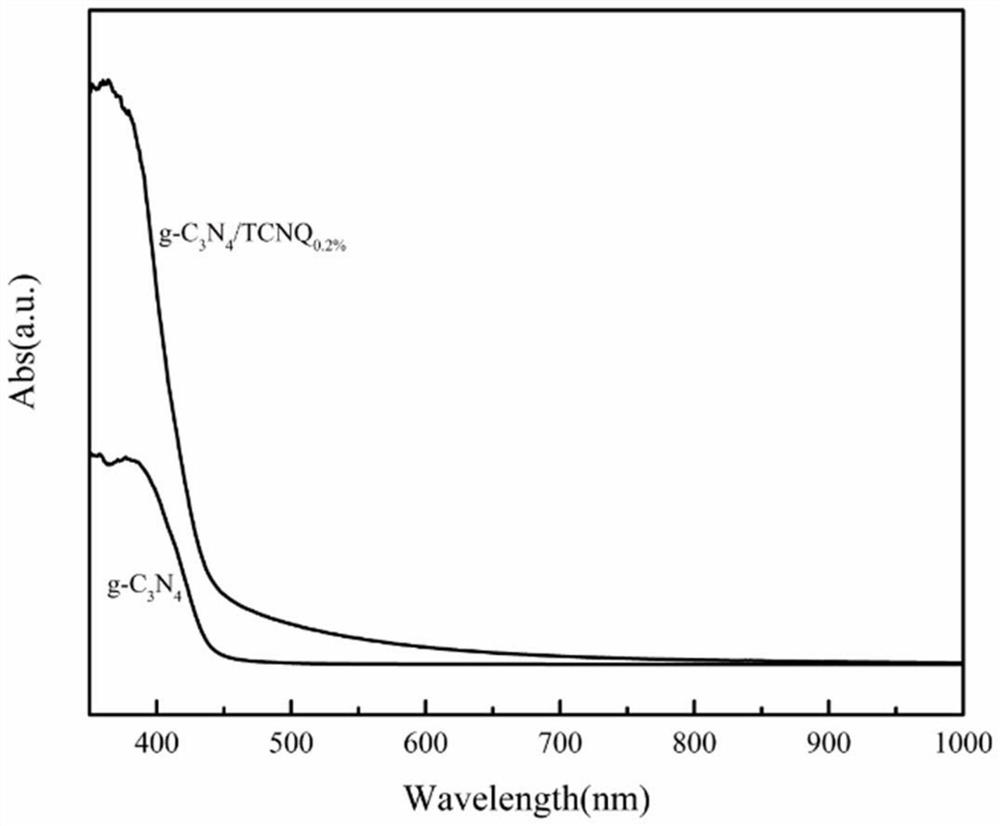

[0026] (1) Add 5 g of melamine and 10 mg of TCNQ into a ceramic mortar and grind continuously to obtain a mixed solid powder;

[0027] (2) Spread the mixed solid powder prepared in step (1) evenly in a quartz boat, place it in a tube furnace, raise the temperature to 520°C at a heating rate of 5°C / min in an air atmosphere, keep it for 4 hours and then follow the furnace Cool down to room temperature, make the layered graphitic phase carbon nitride photocatalyst (g-C 3 N 4 / TCNQ 0.2% ).

Embodiment 3

[0029] (1) Add 5 g of melamine and 25 mg of TCNQ into a ceramic mortar and grind continuously to obtain a mixed solid powder;

[0030] (2) Spread the mixed solid powder prepared in step (1) evenly in a quartz boat, place it in a tube furnace, raise the temperature to 520°C at a heating rate of 5°C / min in an air atmosphere, keep it for 4 hours and then follow the furnace Cool down to room temperature, make the layered graphitic phase carbon nitride photocatalyst (g-C 3 N 4 / TCNQ 0.5% ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com